Before I won the contest I'd been trying to just have as much fun as I could while retaining an original type single piston front disc/rear drum brake system. Of course I keep replacing the calipers, wheel cylinders, master cylinder etc. and I installed braided flex lines to replace the stock rubber ones. I tried a number of different pads and shoes over the years and the most recent and best setup was having Porterfield race pads on the front with custom made Raybestos race shoes in the rear. I kept dedicated street pads, shoes, drums, and rotors and swapped everything and bled the brakes before and after every track day. A lot of work, but the race setup worked so much better on track than stock stuff it was worth it. The biggest drawback was that I would get the rotors so hot on track because of the race pads that I'd crystalize them and have to junk them after a track weekend. Now I'm going big time!

As mentioned in my first post, I talked to Todd at Baer for a while one afternoon. After discussing what I do with the car and my personal opinions on things like aesthetics. He came up with the brake package you see below. There's a few reasons for the way I got certain things that I think might be interesting to others considering big brake upgrades. I told Todd I didn't care what color the calipers were so they sent me Nickle plated!

Although the car's pretty and photographic, I am more concerned with the function, performance, and simplicity of things for The 14 Car than I am about the "look". If a couple sponges rubbing on a balsa wood disc would stop the car faster I'd be fine with that, no matter how silly it looked. So given that attitude, some things that the more show oriented guys get in a brake package I have no yearning desire for. Zinc wash rotor coating is a good example. My brakes are going to be used to their limit and so the wheels, spindles, calipers etc. get covered with brake dust at every track event. I clean everything often but I don't need the "show" look of the zinc. Drilled rotors are another type of option that I don't really need. There's a lot of opinions about drilling rotors that I'm not going to go into here, but for me, I'm good with slotted or solid rotors.

The big rotors are a lot of rotating mass and they will require more power to get them up to speed out of every turn. (read, slow my car down) That mass is also what helps dissipate all the heat generated while slowing the car repeatedly on track. Now, while you might think that the car accelerating slower out of corners will make the lap times higher, the ability to stay at full speed on the other end of the straight longer before braking more than makes up for the slower corner exit acceleration. As an example if I was going 140 MPH at the end of a straight I'd cover a lot of ground in a short period of time. If I can start braking a hundred feet later than I did with the old brakes the loss of time getting up to speed is more than made up for by the time saved traveling at full speed for an extra hundred feet!

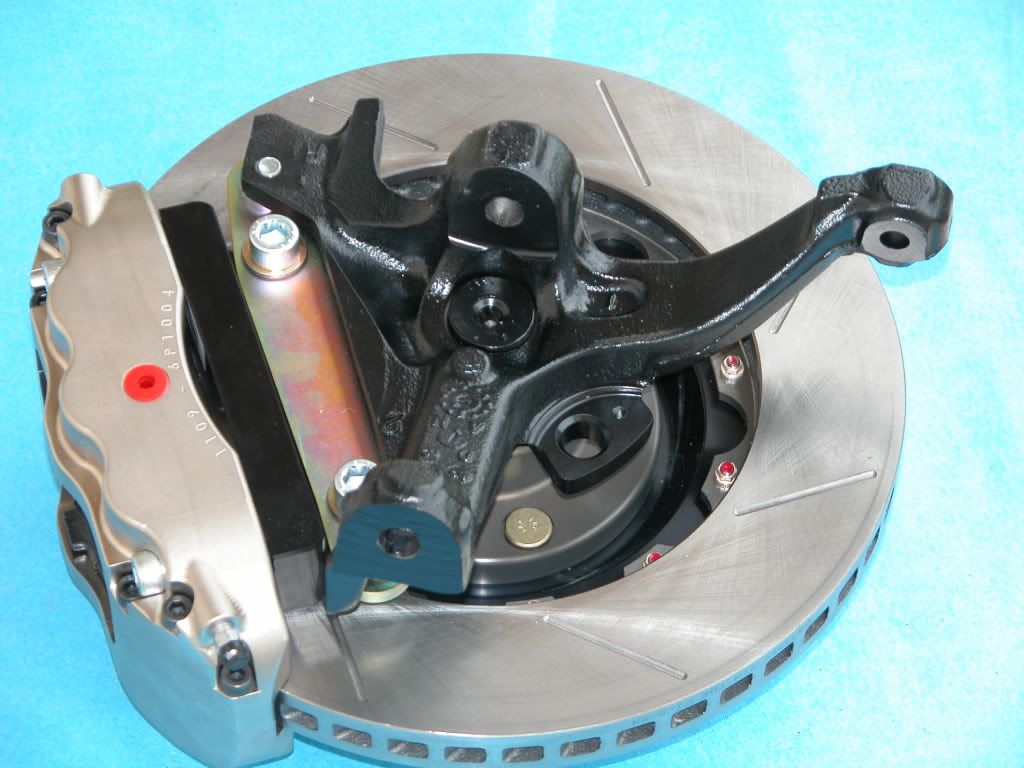

The rotors are a 2 piece design and the calipers are BAER 6P asphalt track 6 piston design with BOTH brake pads moving! (inside joke). The fronts come on a dedicated spindle for the 2nd gen F bodies and the rears are designed to work on the Ford style Moser tapered bearing housing ends I have on my 10 bolt GM rear. These calipers use a modern Corvette design pad so replacements are readily available in different compounds.

The rear brakes are also 14" rotors with the 6P calipers and include the park brake that fits into the center section of the 2 piece rotors. There will also be an adjustable proportioning valve I'm hoping to mount within reach while driving to fine tune the amount of work the rear brakes do.