Thanks Wayne, pushing to get it done for SEMA. Going to be Line-Xing the entire floor panel next.

The boys did a tremendous amount of work for something that will look so simple in the end. Creating a flat firewall on the driver side.

Here is a pic of the original engine bay. The red circle represent studs (total of 11 studs) that were sticking out about an inch through the firewall into the engine bay. These studs are welded to the plate that hold the buster and pedal assembly.

In order to create a flat firewall driver side, the first step was to cut off the studs off the plate.

Next they had to come up with a way to mount the plate to the firewall.

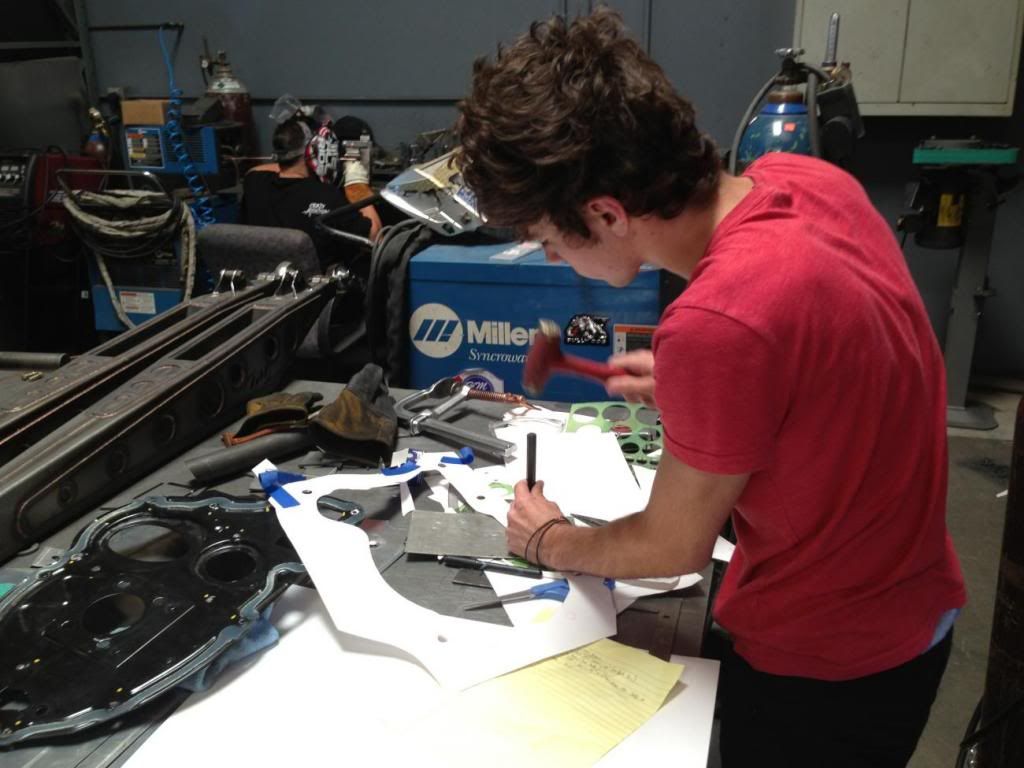

Seth made the template for what would become a ring the shape of the hole.

Next came cutting the shape out on the plasma cutter

Nathan cleaning out the edges.

They cut the heads off the bolts and here they used the plate as a fixture to weld the bolts to the ring.

There's was about another 20 more steps to get to where they welded the ring

The holes were use to rosette weld the ring to the firewall.

Finally, they welded the ring to the firewall with the stud now facing the cabin. Next on the list is making a carbon fiber firewall.