continued from above

New Frame

To stick with the same frame section sizes used in the bolt-on

front subframe (that had been welded to the center frame section) we stuck with the 2x3" rectangular tubing for the center section of the new frame we would be building. This would make it possible to mate it all up at the firewall. Its a good size of tubing to use in any case.

We ordered up more of the 2x3" tubing as well as several other sizes of square and round tube for various fixtures or frame pieces that needed to be constructed. At the same time a pair of mandrel bent "over the axle" 2x4" tubing rear frame sections were ordered. Then the tedious work of fitting the side frame rails into the Camaro rockers was undertaken, which meant more cutting, but with more refinement and measuring involved...

The previous 2x3" frame sections were placed several inches inboard of the outer rocker panels. This meant the old roll cage tubes didn't line up with the frame rails. Our new goal was to "pocket" the inner structure of the exterior lower rockers and move the new 2x3" frame tubing outboard. This would allow the new frame rails to "nest" inside the outer portion of the lower rocker panels. The new frame would be several inches wider and would allow the new roll cage to move outboard and land on these 2x3" frame members directly, which would make for a safer roll cage and a more efficient overall structure.

As the work to fit for the new frame to the body progressed, more and more of the previous fabrication work was removed. I could write a book about the missing welds, poor engineering, and shoddy fab work we have seen on

many cars that enter our little shop, but it isn't worth the down sides. It seems if I say

anything negative about anything ever built, I end up being the bad guy, so I'll just say "lots of stuff was removed", and that we "only removed what was inappropriate for this type of build."

Before the entire frame and some interior chassis structures were cut away, temporary bracing was added to keep the outer body panels square. These tack welded tubes (shown above) will be removed as the new frame structure is added.

There were some hours spent making room for the 2x3" frame rails out in the rocker sections (tack welded in place, above), but it was worth it to be able to get the cage mounted more outboard than it was before. This work gained several valuable inches, room needed to keep the tubes from being where the seat needed to be, to keep cage away from the driver's head.

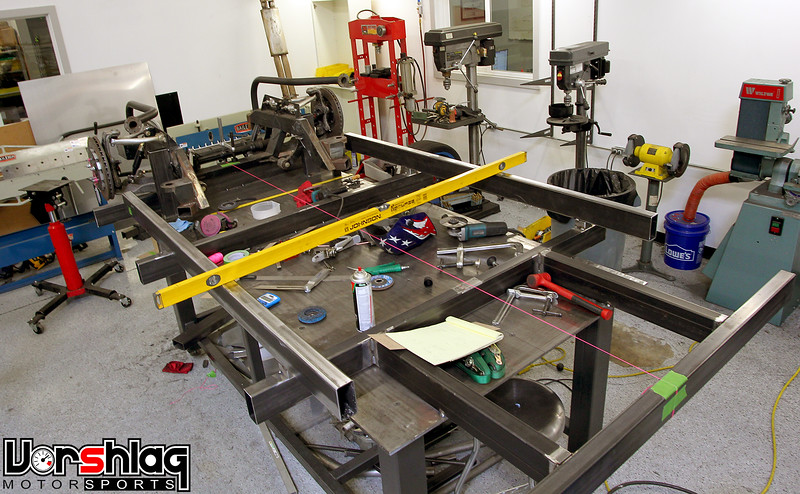

Once the frame rails were mocked-up on the chassis, measurements were taken and a flat and sturdy structure was built onto our 4x8 foot heavy duty welding table. Its not really a "frame table" that I'd like, but for our limited shop space, it works. Then the frame rails were removed from the Camaro tub and placed onto the table structure at the right width... then the body was lifted onto the frame rails, set onto those, and re-tack welded in place.

More Next Time

This work shown above was completed by about May 20th, and this tear-down is as good a time as any to stop this project thread installment. I'll show more of the frame table work next time.

Thanks for reading,