continued from above

The motor mounts use the same Energy Suspension polyurethane bushing we've used on hundreds of LS swaps, which is both rigid enough to prevent drivetrain deflection but

just supple enough to cancel out some NVH. The mounts tie into the front frame/subframe structure and bolt on.

Above you can see Brad and Ryan test fitting one of three different racing seats the customer brought - a Sparco EVO III, an EVOII, and a Lajoie aluminum seat - which I will show next time. They also mocked up a driveshaft with 4" PVC tubing, to check rear crossmember clearance and tunnel position. There's some floor and tunnel structure started here, but I will show more of that in my next post.

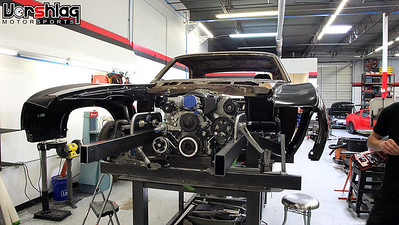

A quick body mockup showed that meeting the desired engine setback would be easier to remove the factory cowl in favor of a fabricated part rather than just trimming it. Again, the firewall had been heavily modified (and yet had zero room for exhaust headers) and the rusty cowl was a mess, so losing all of that wasn't making anyone too sad. Plasma cutter made the initial, big cuts on the cowl, then the body could slide down over the chassis to verify fit...

With the body on you can see the engine setback clearly, above. The Norwood "alumi-fit" 69 Z28 reproduction aluminum front fenders and hood were also test fitted at this stage, to check basic clearances to the engine, tires, etc. Everything looked good and fit as expected.

That shot gives you a better image of what the car will look like when its done. It looks SO much meaner with the wheels and tires fitted, but I will show that next time.

Videos - This Week At Vorshlag

The 69 Camaro has made it into a few of my semi-regular "this week at Vorshlag" videos, and the one below get us caught up to where we stopped here in this build thread.

This

June 15th Video has plenty of 69 Camaro at the beginning to about the 3:38 mark.

What's Next?

Next time I will finish covering the rest of the work knocked out in June and then some going into July, including: the differential install, more floor structure and tunnel fab work, dry sump tank mounting, more front suspension work, and firewall structure work. Oh yea, and the roll cage was built (teaser pic above). Until next time...

Cheers,