continued from above

Left: BEFORE Camaro SS front bumper cover. Right: AFTER with the ZL1 front end

Left: BEFORE Camaro SS front bumper cover. Right: AFTER with the ZL1 front end

We used this "opportunity" to upgrade a number of things in his braking system, exterior cosmetics, seats, and safety gear. The Heritage crew replaced the front SS bumper cover with a ZL1 version, along with the associated ZL1 lower lip and lower grill.

They did a superb job for the money charged (not an insurance repair) and replaced all of the airbags, airbag controllers, ZL1 front bumper cover, and ZL1 rear diffuser. We also did the brake cooling & suspension work shown below, then Brad detailed the car, buffed the carbon fiber-ish hood, and cleaned up the wheels. No more traces of mud from "the incident" and the Camaro looked better than ever.

We addressed the brake cooling issues by creating new 5th Gen Camaro brake backing plates with 3" inlets for cooling air. We made these by hand but scanned the final design for future production after some track testing.

These backing plates are fed by inlets in the ZL1 grill and the ZL1 brake cooling inlet ducts we sourced from GM. But like most factory "brake cooling" solutions, the inlet ducts just pushed air into the wheel well area and hoped it would reach the brake rotors. That's not good enough.

Our crew made these 3" oval duct adapters that fit onto the end of the factory plastic duct tubes. These give us something rigid to clamp the 3" brake cooling hoses to that protrudes into the wheel well area.

The images above show the 3" oval adapters in place and then with the 3" brake cooling hose attached to these + the brake backing plates.

This is the final result - proper brake ducting that force feeds high pressure air from the lower grill, through smooth OEM style ducting, into 3" high temp hose, then into the brake backing plate. The air is then pumped inside the opening of the 14" front rotor, around the front wheel bearing and through the vented rotor vanes like a centrifugal pump. This is how to cool brakes properly. No need for heavier 14.6" ZL1 2-piece rotors, or CCM Z/28 rotors, just proper cooling for the OEM iron brakes. We would need to test this later on track to validate their worth before moving forward with any of this as production parts.

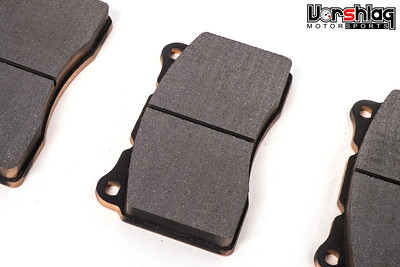

We also flushed out the RBF600 and went with a higher temp RBF660 fluid then upgraded the "EBC Green" pads to proper track pads using G-LOC R10 compound fronts and R8 rears. They are more heat resistant and have a higher braking coefficient but do make more dust and noise. That's the price you pay for proper brake pads.

continued below