Quote:

Originally Posted by Doug1

I've got the passenger side drilled out and coated yesterday with sealer. Will be ready for the drivers side soon. Hopefully, I got it right. :-) I used every hole so I'm short a couple of 1" bolts because of that but no biggie. I'm going today to see if the supply house here has shouldered bolts in stainless so I can use those.

|

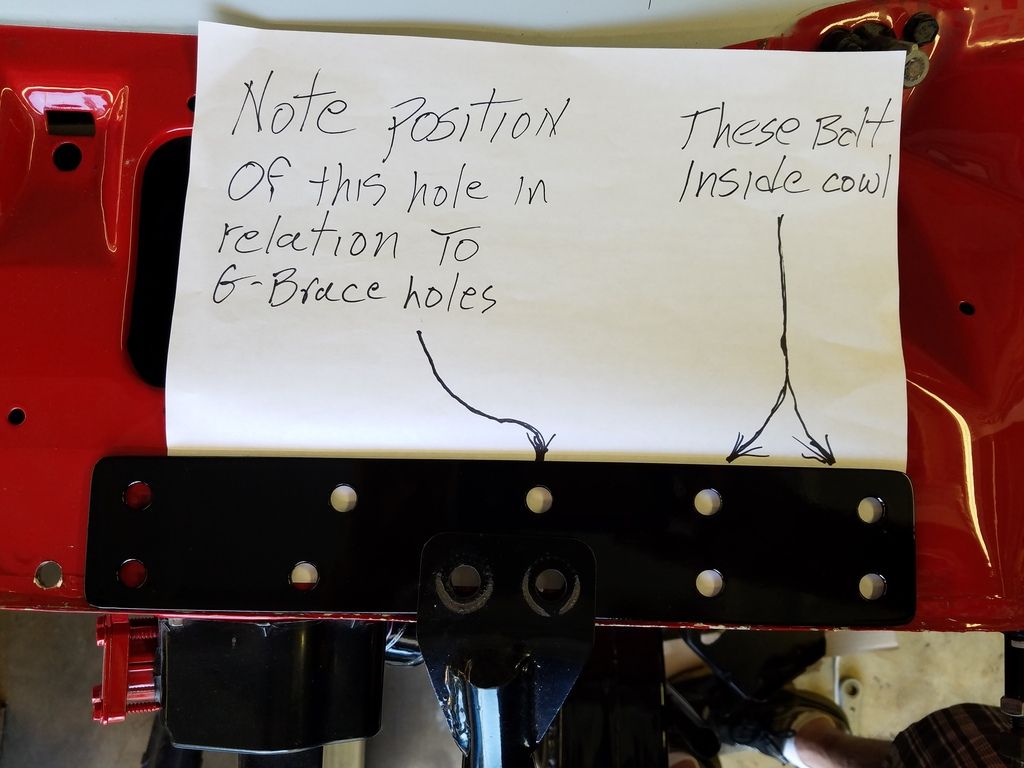

Narrow plates on passengers side and holes are slightly off center so you can flip them end to end or top & bottom for better fit against the short right angle lip on various cars. Wide ones on drivers side. The one notched for the wiper recess there is only one way it fits. Note bolt pattern for top plate in pic below so it lines up with the notched bottom plate. And be careful not to drop a nut down the side of the cowl. If you're short bolts I fear you tried to put a wide plate on each side. They're designed to get the most support we can without interfering with the stock plastic cowl screen or the 70-76 hood/cowl gasket.