continued from above

FRONT STRUT TOWER REINFORCEMENT

The second common weak point on the E46 chassis, as with many McPherson strut cars, is in the actual strut towers. The sheet metal is a bit on the thin side and virtually all of the vertical suspension loads pass through the strut and into the chassis via these two towers. With a big enough impact you can deform or crack the sheet metal here. It's even worse with sticky race tire loads. Sometimes the towers develop cracks simply from fatigue - again, soft bushings allow for a lot of extra squishy movement, which flexes the metal over time.

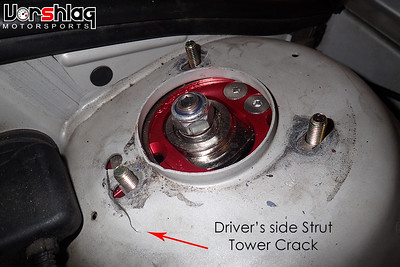

Below is a common upgrade we do on many BMW chassis, where we reinforce the tops of the strut towers. The damage shown on the silver E46 M3 track car below is a perfect example of why this work is needed.

This customer saw the tower reinforcements done on the Chainsaw Massacre E46 M3 CSL-clone and wanted the same thing done to his dedicated M3 track car. Good thing, too - when we pulled the strut tower brace off we found a series of massive cracks hidden from view, which you can see above.

The cracks were each "drill-stopped", TIG welded, sanded smooth, then a pair of the BMW E46 reinforcement plates were welded into the towers from underneath - effectively doubling the thickness here. The areas were primed and the car went back on track.

Before the color matched paint arrived to re-shoot the tops of the towers this car was in a track incident. This snapped the right front Bilstein Club Sport inverted strut like a twig, ripped the tie rod out, and broke the control arm and wheel - but the strut tower was fine. I can say with confidence that this reinforcement work saved this strut tower from total annihilation. Doubling the thickness of metal here is key.

Back to the E46 M3 CSL build - Ryan started by pulling the stock front suspension off and out of the way. Then we ordered these stamped steel E46 strut tower reinforcement plates from BMW (Part # 51717036781 ), which are rounded and match the shape of the E46 strut tower from underneath. These are often just slipped in and bolted between the strut tower and the top mount, but we would weld them on for more strength and longevity.

The paint was stripped off the top of the strut towers with our OBX stripper tool. Then the reinforcement plate was bolted in using a fixture and TIG welded around the round opening at the top and along the slotted strut tower holes. There was some prior damage to the lip of the strut tower opening that we repaired and now looks new.

The paint was also stripped from the underside of the tower and from the reinforcement plate. Ryan MIG welded the plate to the tower from underneath with 6 stitch welds as shown. These areas were then covered with seam sealer and primer paint.

SEAT TESTING + STRIPPING THE INTERIOR & ENGINE BAY

In preparation for the roll cage and seat mounting we needed to get the chassis completely stripped and ready for welding. Since this was a "complete build" we tackled the additional work of removing all of the body wiring, tar insulation, and even some unnecessary unibody structure. When you are looking for hundreds of pounds of weight loss you have to chase every pound!

We had Mr Chainsaw test sit various racing seats in our lobby. He liked the

Sparco Circuit II seat, which have an integral halo section to prevent side impact neck injuries and high leg bolstering. I also like this seat and have it in one of our shop cars. After we test fit one in this car, I ordered two new seats from Sparco for this build.

The work of removing the dash, wiring, and plumbing from the car to get it down to a bare rolling chassis takes time. It isn't super exciting work but it is all necessary when you are looking to minimize weight as much as we are here. "Just leave the stock wiring harness" might be appropriate for some builds, but not one this extreme.

continued below