continued from above

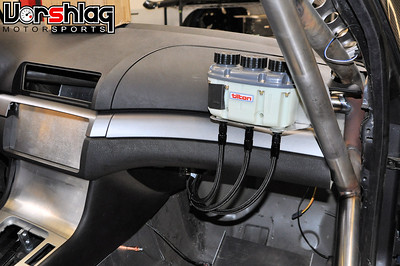

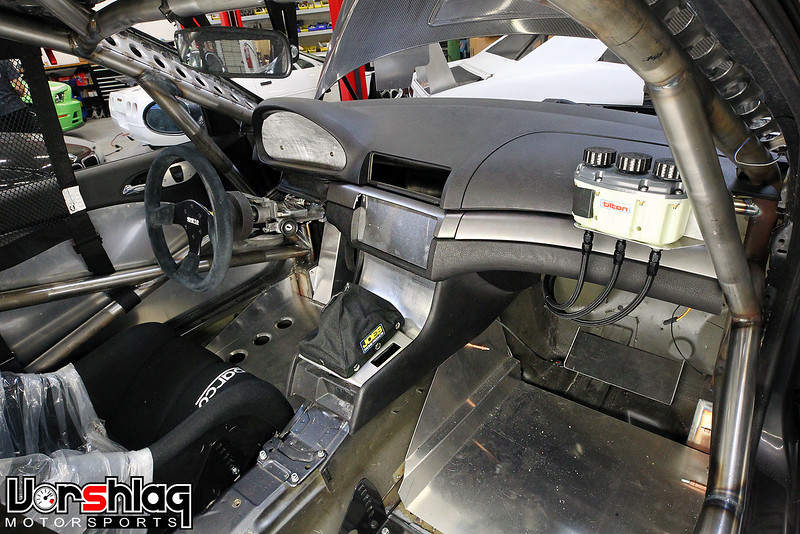

Another Tilton triple reservoir was purchased (also like on the 69 Camaro), which will feed the twin brake and single clutch master cylinder from the OBP floor mounted pedal box. This Tilton unit was mocked up and then mounted on the passenger side. Why have this in the passenger compartment? Three reasons. 1) Being visible to the driver makes it easy to see if fluid LEVELS drop during a session (indicates pad wear or a leak). 2) It makes it easy to fill the fluid levels, not buried down by the floor mounted pedals. 3) It keeps the bulk of the fluid away from heat in the engine bay.

A few weeks later Ryan went back and made -4 AN braided lines for the reservoir and ran them to each master cylinder.

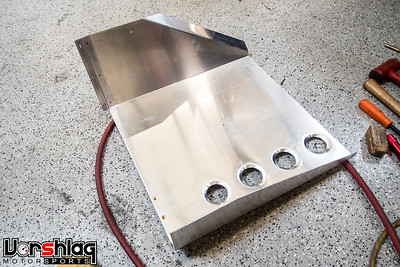

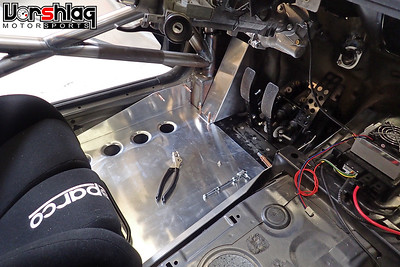

The spot your heel rests on at OBP pedal box was tied into a flat, false floor made of aluminum. A formed sheet aluminum dead pedal was also built and tied into the same section. These false floors are commonplace in race cars, and with the unusual non-flat floors of the BMW E46 they are pretty much a requirement if you remove the carpet and massive foam backing.

These were formed from 6061 sheet then dimple die holes were added on the press. We will add grip tape to the surfaces later, to keep your feet from sliding around if they get wet. The passenger side false floor was started but still needs some dimple die work.

We couldn't leave the stock steering wheel in place so we ordered a Sparco wheel and Lifeline quick disconnect hub. This wheel fit the driver's position and has the right covering, and the Lifeline is the best quick disconnect on the market.

Window nets might seem a bit extreme for a car with roll up windows, and it is unusual. But for a "street car" this M3 has an unusually high speed threshold, so the safety gear isn't being skimped anywhere. This mesh window net has great visibility but keeps "your arms and hands inside the ride at all times". We will add a center net later as well.

A lot of aluminum panels were built, which help fill holes in the dash where the radio, HVAC controls, and stock gauge cluster went. An AiM digital dash, possibly a rear view camera/LCD screen, and the fire pulls and main battery kill will go back into these places. A new set of "Titanium" OEM trim panels was ordered from BMW and installed to fill the gaps between the 2-pieces in the upper and lower dash sections. We will get a little crazier with interior panels and finishes before the car ever does an Optima event, but its already a lot better than the plain "gutted race car" look.

continued below

RADIATOR INSTALLED + HOSES BUILT

Spec'ing the radiator for this project took a little bit of work. This 7.7L motor would need the biggest radiator we could fit in front of the motor. We also wanted to duct the hood and "roll" the radiator forward at the top, so that meant we wouldn't be using an off-the-shelf aluminum E46 radiator.

I asked Ryan to clear away anything in the way between the frame rails then measure for the widest core we could squeeze in there (27"). The center portion of the lower stamped piece of the radiator support was completely cut out. He then built a cardboard mock-up to verify the max height core possible. Then we had to spec the hose outlets for an LS engine accessory layout, with the suction on the passenger side and water pump outlet on the driver's side. The goal was to shove as much of the radiator forward under the radiator support as possible without running into the front nose or crash beam. Unfortunately the headlights became a limiting factor for forward roll of the radiator, so the bottom of the core was pulled back closer to the balancer, to gain more angle and radiator height room.

The mock-ups and other specs led us to a BeCool 60229 radiator, which was custom ordered back in May. It took a while to be built and shipped here but when it arrived Ryan made brackets to mount it in the layout we wanted.

continued below