continued from above

Myles and Jason worked on the control arm design based off the S197 Mustang design (2005-2014), using an S197 spindle/hub we keep on hand for design and testing purposes. Once the geometry was dialed in on the wheel testing task above, Myles ran some calculations using the OEM S197 front LCA. We bought the later S197 spindles (which upgraded from an 18mm to 19mm ball joint shaft) and Howe ball joints and threaded collars.

These ball joints are replaceable and the threaded Howe collars are more easily incorporated with a custom LCA design, and were used on the mock-up single plate designs to test geometry (above left). We talked about a tubular version but felt that a boxed, plate steel design would be more robust and accurately repeatable for the mirrored side-to-side design.

This later version had some round windows that we would later fill in with tubing to make the boxed structure stronger. Myles poured some hours into this design and the fabrication work.

We don't do "weld pr0n" around here, because most of that Instagram welding isn't practical, and it isn't always the right way to do ti. You can look at all of our builds and won't see any pics of "stacking dimes" - because that is better left to ego posting. Proper cleaning, the right rod, adequate shield gas flow, accurate heat, and the right penetration are what we shoot for here.

Above left you can see the tubing sections being added to the holes, for strength. Lots of tedious work went into these boxed Lower Control Arms. The control arm mounts were tubular sleeves made to fit within the AJE subframe, and to work with Whiteline bushings we ordered to fit the OD and ID needed.

Having the sleeved mounts aligned was critical, so a couple of welding fixtures were machined to fit the ID of the tubing as well as set the spacing to mach the crossmember. We will keep these on hand, along with our CAD designs, in case we ever have a need to make these LCAs again.

The rounded ends at the ball joint mount were "boxed" in with a final piece of steel. All of the parts were CNC cut but that doesn't make the welding and prep work any easier. After both arms were fully welded the Howe ball joints with S197 stubs were fitted with the rubber boots. No distortion and they threaded right in.

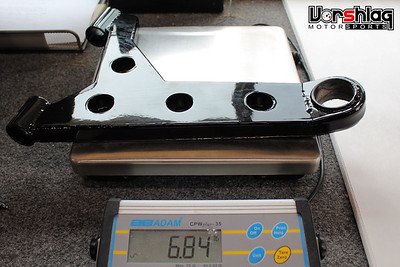

This might seem like an excess number of pictures for Lower Control Arms, but these are critical to this entire build and we built them in a new way - for us. They came out very strong, rigid, and relatively light weight. They will allow us to use a modern S197 spindle / hub / brake / ABS with a cost effective tubular crossmember from AJE - that had LS motor mounts built in.

I took the LCAs and trans crossmember to have them powder coated, which wrapped up that portion of the fab work. This brought the build into early April 2020, and I will show more of these parts in a future post.

continued below