continued from above

I admit to being a little worried that this pump made for a Ford would fit the GM LS7 engine (because there are 3 GM LS engine pulley fore-aft placements), but with the help of KRC we ordered the right parts and it all bolted up. One less thing to worry about, and with a proper cooler and some hoses to the rack we should be golden.

FUEL SYSTEM PLUMBED & HOLLEY EFI WIRED

Back in early June we had convinced Adam that the stock fuel rail was going to be trouble to work around, due to the planned fuel system plumbing route on the other side of the engine bay.

An aftermarket Holley LS7 fuel rail kit was ordered and installed in late June. This will allow us to install a fuel "return style" fuel system in this car more easily and cleanly.

Along with the rail kit, the pressure regulator also came from Holley. We're trying to stick within this brand when we can, for several reasons.

The Holley Terminator X-Max EFI system was chosen, based on experience with our tuner Jon Simpson as well as Evan's own experience. This system has a lot of power and control for the cost, and near infinite tunability. It can also control the drive-by-wire LS7 throttle body and pedal.

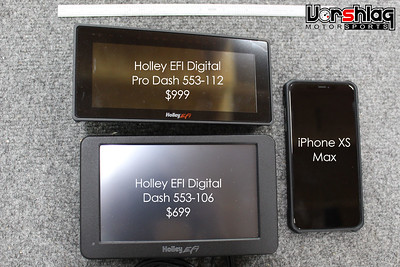

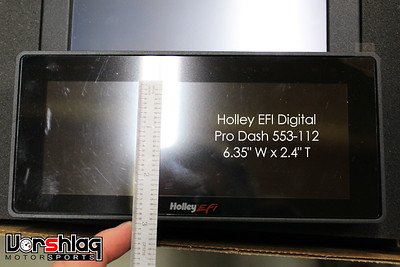

We gave Adam several digital dash choices as well, including these two Holley versions above. He went with their Pro Dash 553-112, which is shown above right. This has touch screen capability so you can literally create buttons on the screen to touch to turn on or off systems. Full color TFT display, should be pretty slick.

The EFI parts arrived in July and Evan got to work. An Odyssey Red Top AGM battery replaced the old lead-acid battery in the trunk, which was wired into the Holley system for initial testing. We will mount this with one of our brackets for the Odyssey 75-25 series to secure it in all 3 axis.

Within a few hours the plug-and-play harness was installed, the ECU was wired in, and the digital dash was connected. It all fired up and communicated perfectly.

If we had oiling and fuel systems on the car we would have cranked it that day in July! But by the time that the Fragola parts arrived for the plumbing, Evan had left to start his own shop. Luckily he came for handful of days back to wrap up some things on this Mustang in late August/September 2020.

The OEM hinges immediately became an issue. These spring loaded units are big and bulky - they take up some much needed room under the hood, where we needed to place the fuel pressure regulator and coolant reservoir. We found some fancy billet versions that were much smaller, but in the end the customer decided to go with the stock units sans springs.

Evan had spec'd all of the components for the fuel system so he got to work mounting and plumbing everything from the fuel cell forward.

The Radium fuel cell feeds a Radium fuel filter, mounted in one of their heat sink mounts, which is installed in the trunk. An AN -8 line feeds the engine and a -6 AN line goes back to the surge tank return. These pass through a bulkhead in the trunk, and we will build a firewall to separate the trunk from the passenger cabin.

The hard lines were routed above the frame rail and subframe connectors, so they are not the lowest part of the car. The lines were secured with Vibrant dual line clamps throughout.

Once they reach the engine bay and pass through another pair of bulkhead connectors they feed to the regulator and fuel rail via Fragola braided lines.

By September 4th the fuel system was fully plumbed and the Holley EFI system wired, other than a few things like fan relays. We just had a few more things to wrap up before taking it to the painter.

RACK AND PINION STEERING & HEADERS

This is where brad jumped into this project to wrap up a few things before the car went to paint. The main item missing was functional steering - we had no steering rack or steering shaft connection. We also needed to final install the long tube headers, which had only been test fit before.

After Jason and I looked at both SN95 and Fox racks, I purchased a brand new Fox Mustang GT power steering rack, which has a known amount of travel and 15:1 assist. This was one the AJE crossmember was made to accept. This was installed and it was time to find the right tie rod ends to connect the Fox rack and S197 front spindle.

I purchased both Fox Mustang and S197 Mustang tie rod ends - these arrived and we got to work finding the right solution - which might include a hybrid of both.

Seeing both parts let us measure the different tie rod threads but similar tapers on the ball joint end, where it needed to connect to the steering arm on the S197 spindles. So the Fox tie rods were utilized.

With the rack connected to the spindles it was time for the final install of the long tube headers. We needed these in place to verify the steering shaft clearances.

continued below