ep, the pilot bearing was destroyed, so the transmission needed to have some repairs done. Anaheim Gear performed the needed shaft repair by making a sleeve for the pilot bearing surface vs. a whole new shaft. New synchros, blocker rings, pads, etc. and she's like new again.

But, why did the pilot bearing fail? When this engine went in the block was a new GM part along with the bellhousing. Should be good, right? I was so wrong.....

Using the new Bowler T56 alignment plate, measurements were taken to determine the radial and angular/axial misalignment. For radial, 0.005" Total Indicated Runout is considered okay, and 0.002" on the axial for driver cars, 0.001" TIR for high-RPM cars. So the radial is measuring the runout on the bore of the hole, the axial is the measurement on the face of the plate.

Though the radial runout was within tolerance, the axial was 0.011". Yep, that's what took out the bearing, and I'm surprised it lasted as long as it did.

So, how to fix the axial misalignment? The traditional way is to use shims that mount between the engine block and bellhousing. But I can't seen to do things the easy way......

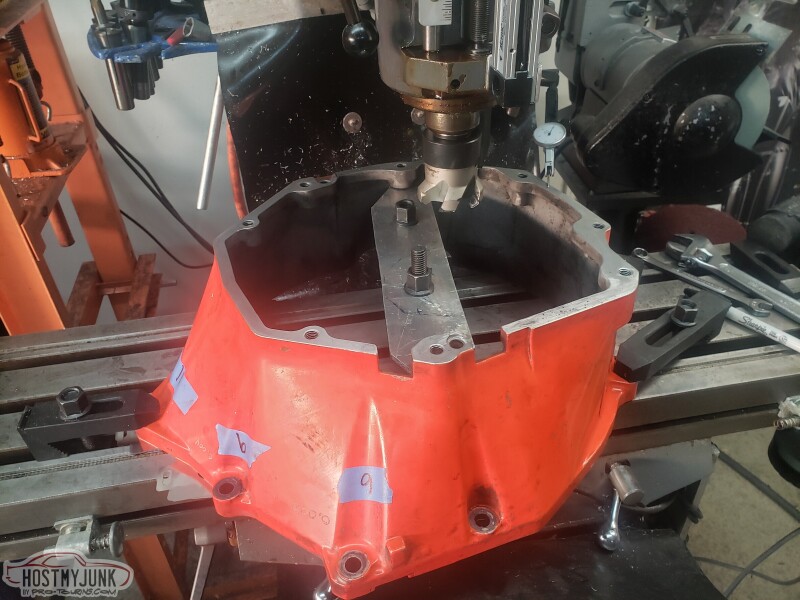

My friend Jeff was nice enough to let me spend the better part of a day using his mill to machine the face of the bellhousing to get it within tolerance. It took five setups to get it right, one heavy pass to get somewhat close, then multiple passes taking just a 0.001" - 0.002" and then checking on the engine. It's under 0.001" now without shims, but it was a PITA to get there. The cross-bar in the setup shown in the photo below was removed as even just a small amount of clamping force caused enough part deflection to create a wavy surface at those locations.

Lesson? Always check the transmission alignment even on new OEM parts.

Clutch:

I'd show a photo of the removed LS7 disk and pressure plate, but instead show just one boring flywheel photo showing the 45k+ mile LS2 flywheel. It's still in good condition, and for how well it works, feels, and the price point, it's a great bargain for many LS builds.

Differential:

The housing was checked for straightness by Speedway Engineering, and a local shop checked the posi unit and replaced the bearings. The C7 bearing hubs appear to be in good condition and were re-used by bolting them back up to the MillerBuilt housing ends. The MillerBuilt parts have been excellent and have cured all of the pad knockback issues the car had experienced prior. Plus, all four corners run a common C7 hub which makes spares a lot easier to deal with.

Being super fortunate, a new set of mid-1980's vintage 12-bolt 3.42:1 gears were still in possession of a forum member that no longer needs them. With the poor state of gear manufacturing for our older builds, these things are worth their weight in gold. They were sent to GearFX for REM finishing and came out beautiful: