Date: around 12-27-22

Back in 2010, I contacted The DriveShaft shop to solve a vibration issue in the GTO. They made me a CV driveshaft that use a CV at the slip yoke and a u-joint in the rear, which solved my vibration issues. Since then, many other A-body owners have done the same thing with the same, great results. When I built the Cougar, I wanted to go a step further and do a double CV shaft. That too had amazing results. If you look at any modern, RWD muscle car, that is exactly what you will see.

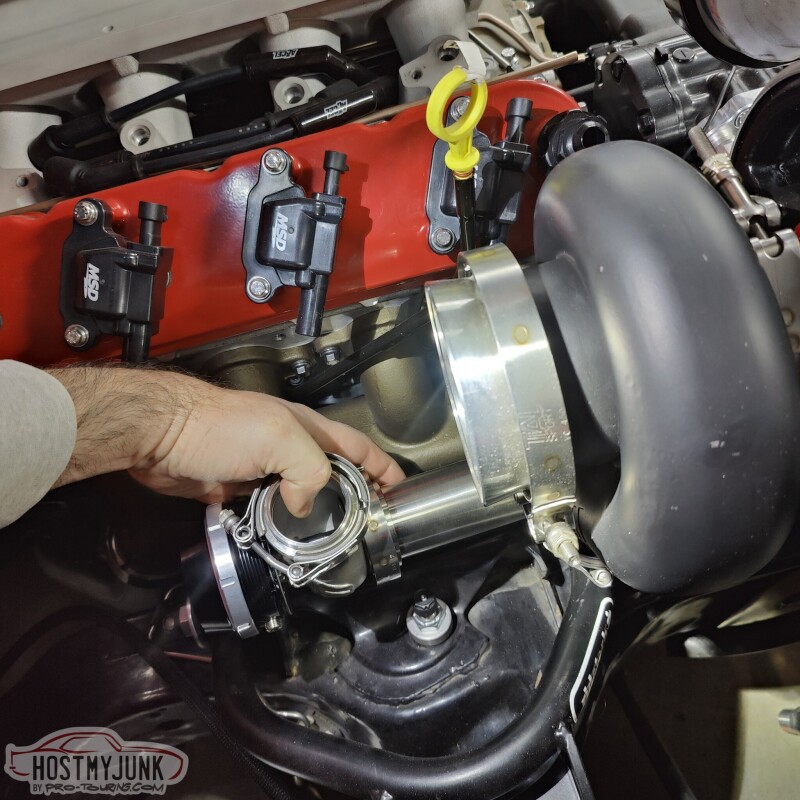

This version of the GTO will also get a dual CV driveshaft and this is the second part of that puzzle (the first being the CV pinion yoke). This slip yoke will use their new, non-plunging CV. This is the same CV they use on their high HP Nissan GTR and other driveshafts.

It's a tight fit, but there is a minimum of 3/8" all the way around the yoke. (what the hell was I thinking, twenty years ago, with the sheet metal screw?!)

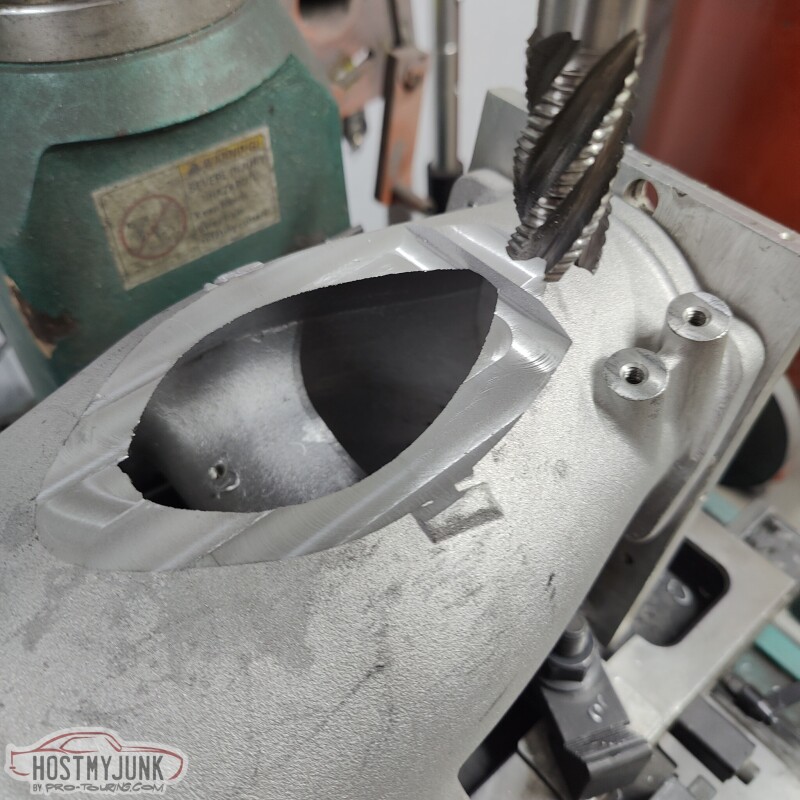

Vic made a fixture to hold the intake lid on the mill. We positioned it at the approximate angle of the hood.

We took about 3/4" off the peak of the bubble and this was the hole that was made.

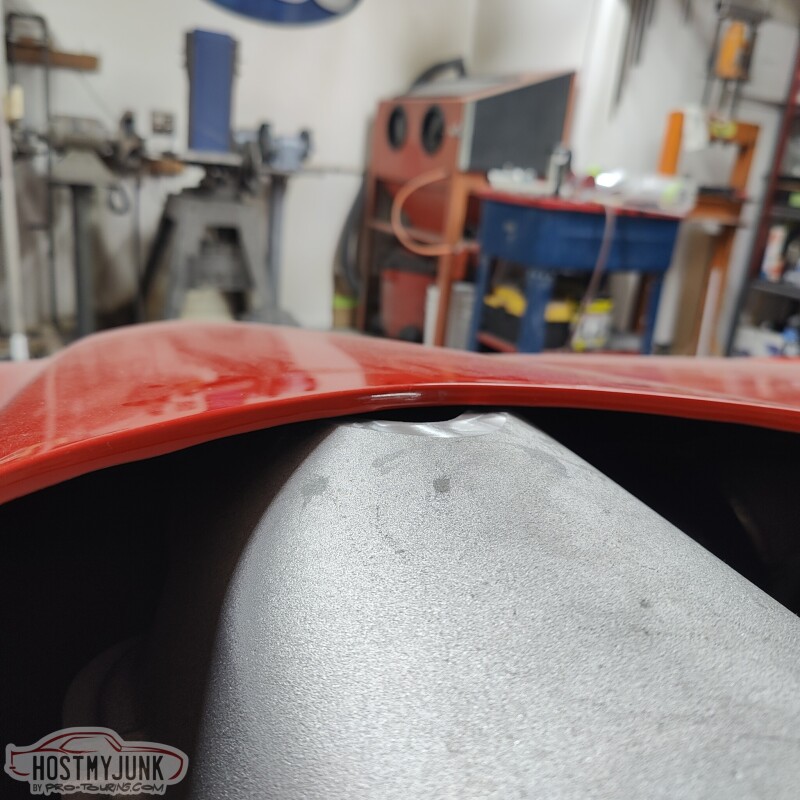

And the hood closed. As you can see, it is really tight, but nothing is touching. We are going to take a little bit more off to make room for the eventual plate that will get welded to cover the hole.

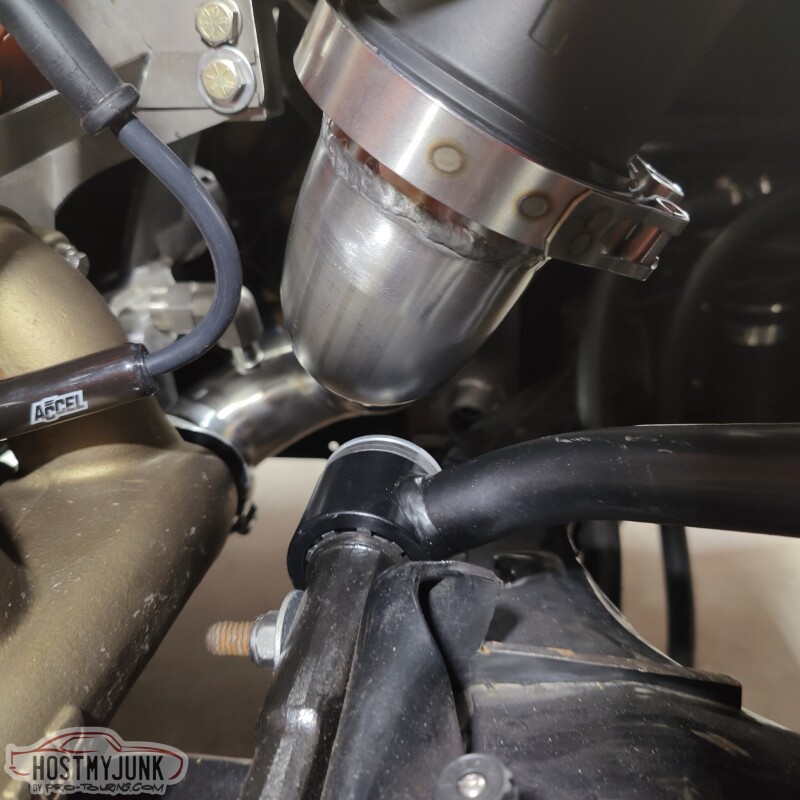

This is the current thinking on wastegate placement. My only reservation is that it be under the downpipe and will be a pain to get to if I have to do something with the wastegate.

The upside is that it will have excellent, priority flow and will merge back into the downpipe.

If anyone has thoughts on the wastegate placement, please chime in.

Andrew