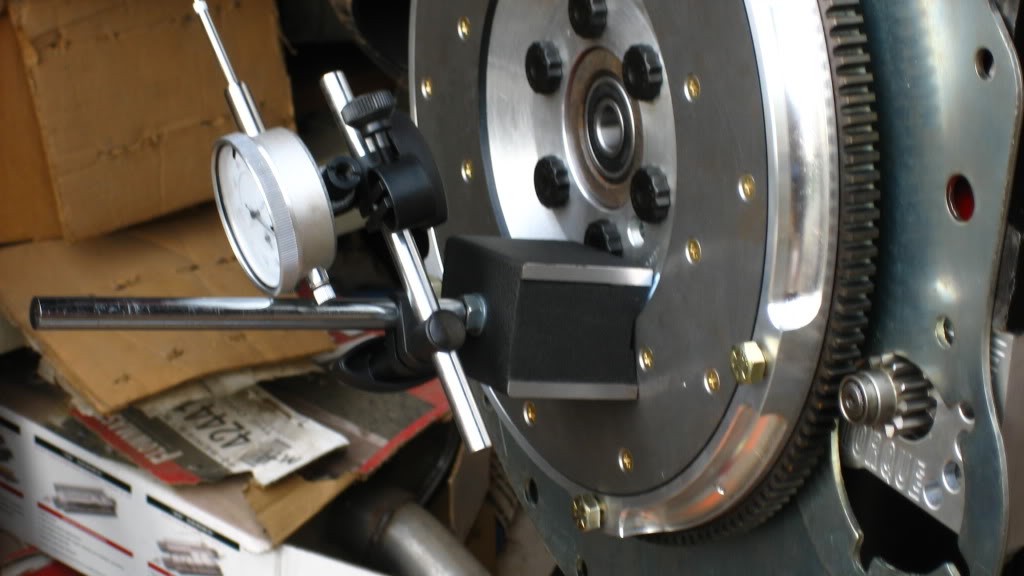

Aluminum isn't magnetic:

Much tougher to find a good mounting position for your dial indicator when doing a bellhousing alignment if your magnetic base indicator doesn't stick to a good portion of your flywheel. I had to use the bolts and the friction surface simultaneously...it was stable though. This was by far the most tedius task of the whole process.

About the bellhousing alignment, there is plenty of information online about how to do it.

www.classicchevy5speed.com has a video, and there are tons of other resources... if your engine is out of the car, I would recommend you do it yourself. It may take a weekend of zen-like patience, because you're knocking dowel pins in and out, positioning your dial indicator, and bolting and unbolting your bellhousing, but it's not difficult.

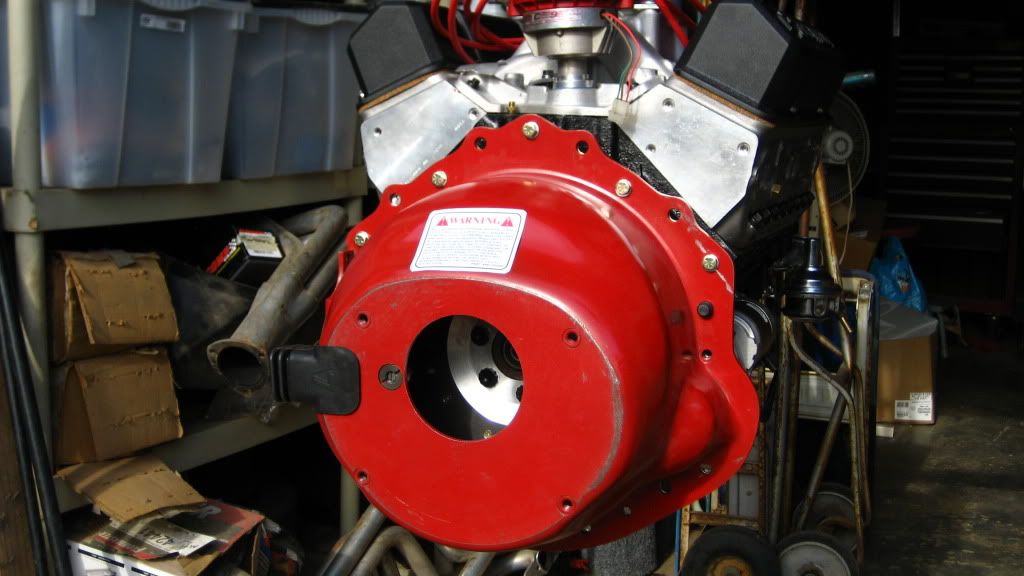

Here's the bellhousing I am using, Lakewood 15030:

In conjunction with the pilot bearing I showed you, this particular Lakewood is used to adapt a Ford-input-shaft TKO to a small block chevy. The Ford input shaft is roughly 0.3" longer, so the bellhousing is longer to accomodate. I have read (and believe) that the Quicktime bellhousing (RM-6064) is more spot-on than the Lakewood, but I got this bellhousing used so it was worth a try.

My remarks on Offset Dowels

In addition to the straight dowels, I bought all 3 offsets: 0.007, 0.014, 0.021 to have on hand. The dowels themselves come with no mention of where the high/low point actually is on the dowel, stupid. Anyways, what I did is just put a straight dowel side by side with an offset dowel and shine light through them. A little crude, but my brother and I both came up with the same point, so I was satisfied. After 6 alignment tries and the typical dial indicator math (a couple just to ensure repeatability), I came within the 0.005 tolerance using the 0.007 dowels clocked at about 12:30. Parallelism was within 0.002 as well. My experience, Lakewood isn't so bad.

To round out the weekend with some eye candy, I mocked up my 10.4" Centerforce dual friction clutch & pressure plate (DF161739) on the flywheel (note again that the pressure plate bolts I show are for mockup only...will use proper hardware for final install):

Centerforce lists 3 dual friction clutches for SBCs:

DF161056 $ XXX ftlbs <--weakest one

DF161675 $$ 430 ftlbs <--marginal for me if I decide to run slicks

DF161739 $$$ 530 ftlbs <--just right

Summit racing lists the clutch I got for Pontiacs only...but a call to Centerforce said that it can be used on SBC's as well.

Well that was 2 days worth of work; thanks for tuning in. Getting there!