Well I retired last year in March and went to New Mexico for the Summer. Back in AZ now and decided to really work on the Camaro while the weather is cool. My goal is to start the engine by the end of February to simply get me motivated to take the next steps. I wonít be able to drive it yet but that is the next step before blowing it apart for painting.

Bringing the electrical system up one circuit at a time works best for me to avoid becoming overwhelmed. The engine wires will be the last thing I do when everything else is figured out.

I decided to put in a trunk contactor so I can isolate the electrical circuits when the car isnít in use. I will have a constant battery circuit for the GMPP ECU.

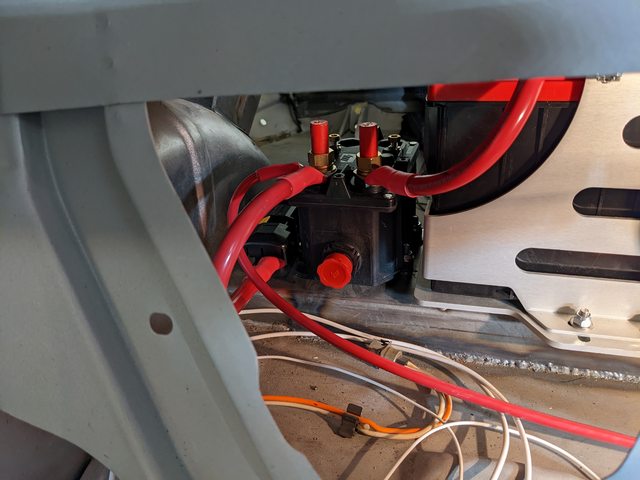

The battery, contactor and a 500AMP main fuse to protect the battery cable are all installed. There is a local place that makes really nice cables.

With the contactor I can manually close the relay with a push button and turn it off when not needed. The trunk aux. fuse box and fuel pump PWM controller can be powered now.

I bought a new power probe and it is a really convenient way to power individual circuits. I finished the fuel pump wiring and was finally able to spin the fuel pump in the tank by simulating an ECU pump turn on signal with the power probe.

My son also bought me a nice Fluke meter for Christmas.

I ran a new power wire from the trunk panel to the original GM fuse box so fuse box power now comes from the trunk panel and not the horn relay in the engine bay. I made a temporary splice to get the engine running but will add a fuse later in the trunk to make it safe. The wires look old and worn out but they are soft and don't have any nicks or corrosion since the car was stored inside most of its life. The stock harness and fusebox will mostly be accs. and lighting circuits. All the engine circuits will be new, modern wiring for reliability.

It was really nice to have the Ignition key working and all the battery and Accs circuits working. Feels like the car is slowly coming alive again.

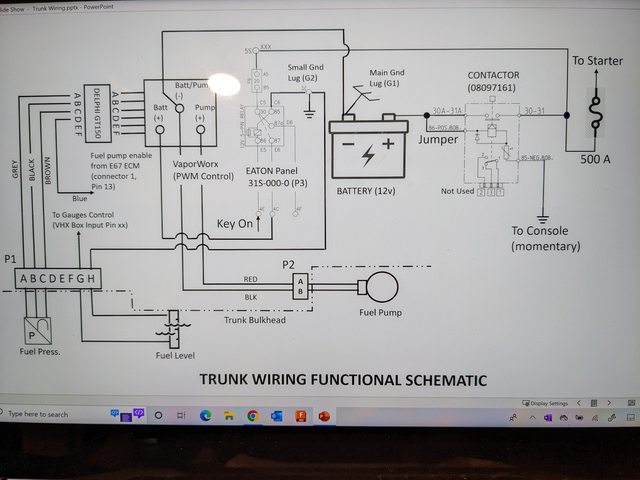

I created a schematic so I would not forget how it is all hooked up (again).

I decided to play with the power probe and hooked up the DSE multi-speed wiper circuits and tested them. Everything works fine and I still need a lot of wire clean-up.

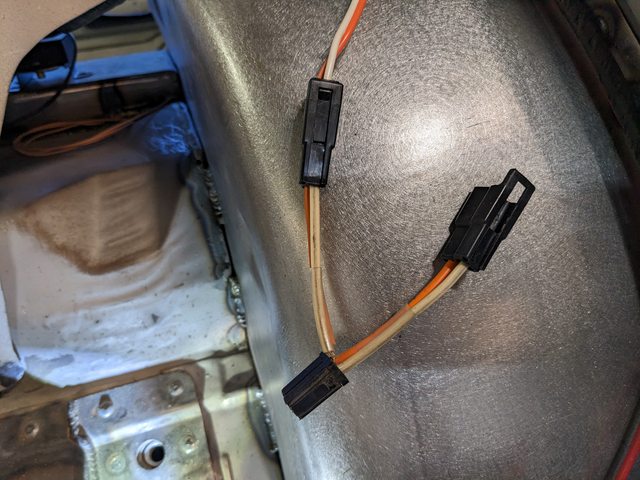

The RS sail panel lighting was always pretty lacking and I decided to add a dome light circuit and the under-dash courtesy lights. To have both a dome and sail panel light harness meant I needed to make some sort of pigtail adapter. I was going to reuse the original sail panel light harness but it was too stiff after all the years. I bought a new repro. harness and used part of the old harness to make the pigtail to power dome and sail lighting.

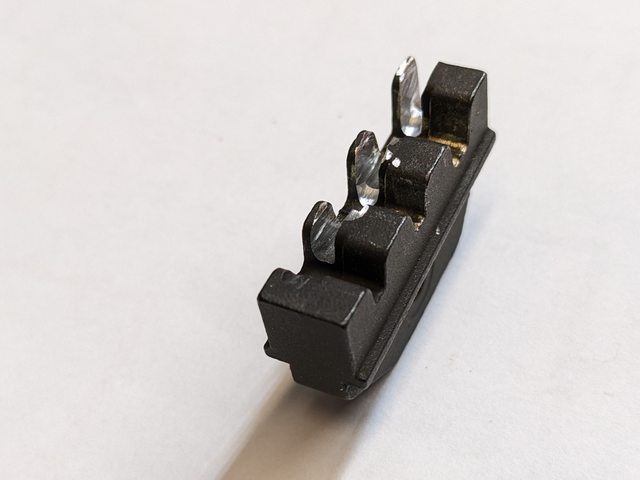

What should have been a 30 minute job turned into several hours trying to figure out the crimping arrangement. I thought I had the right tools but the MSD crimper mangles the little terminal tabs.

I did a little online research and found someone who just modified their crimper inserts by grinding a groove so I grudgingly did that to mine. Hopefully they will still work for normal terminals with a tab clearance groove cut into the one jaw.

The simplest of circuits is done and all the interior lights work now.

The dash lights also work except the VintageAir panel is too dim. I hope there is a burned bulb, or something easy causing that.

Next week I am going to wire up the Dakota dome light dimmer circuit.

Then I will bring power to the Dakota under-dash control box for the gauges. I also want to get the battery cable to the starter and power up the GMPP fuse panel in the engine bay.

Once the engine bay panel is powered the first thing I want to do is get the drive-by-wire throttle pedal working. That will seem like a big milestone.