Final post for now, mock up of some shiny bits!

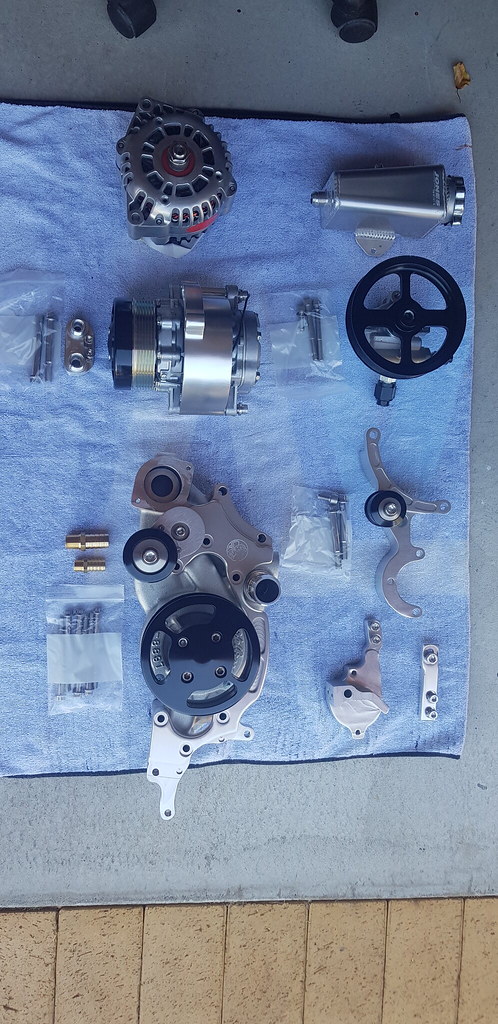

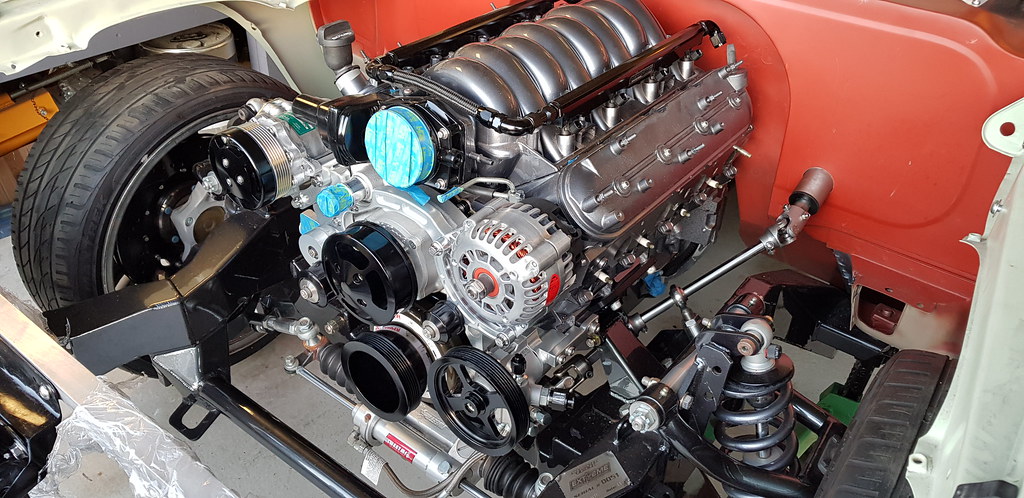

I custom ordered the Drive Junky setup with brushed components and black pulleys to break up the silver a little bit, matches well with the scheme I'm going for. Absolutely beautiful kit, great instructions, everything went together perfectly.

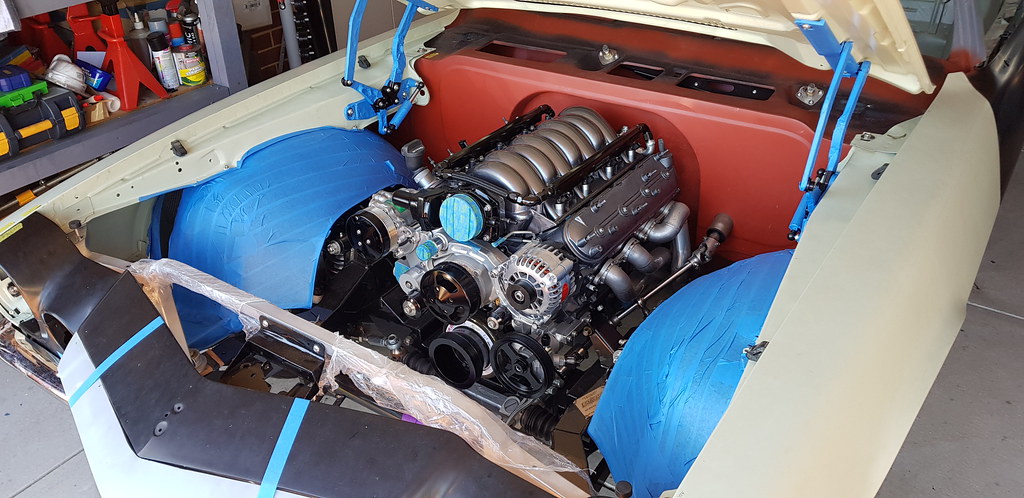

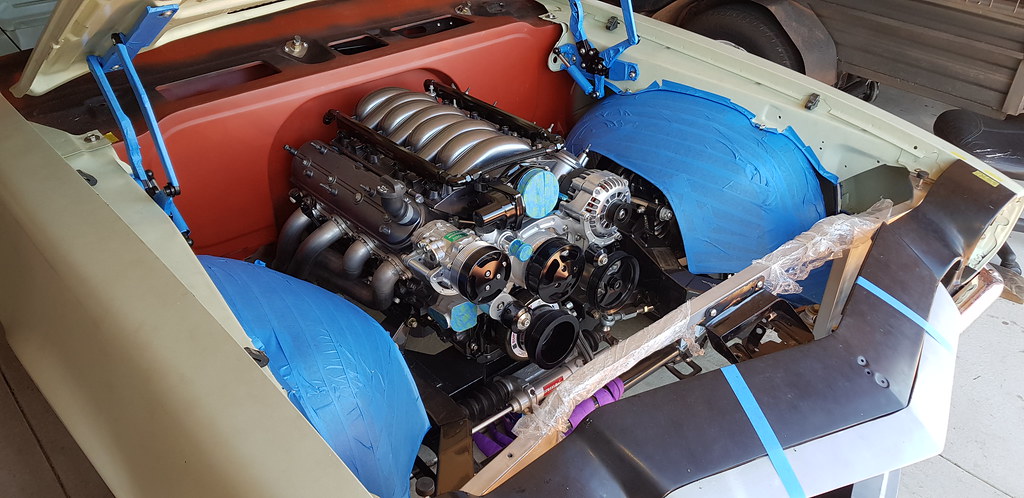

Next up is some carbon from Anvil auto, front spoiler and inner fenders, front spoiler fits decent, may need a little adjustment but that may be due to my aftermarket sheetmetal.

The inner fenders are a little disappointing in quality / fitment in my opinion, thankfully the areas of concern are not visible and can therefore be modified / worked, cant deny they look great though, even when covered in tape. I was concerned they would hit the frame with the modified subframe mounts but they tuck in nicely with the Speedtech Extreme frame.

That's all for now, the car is currently having all the gaps sorted out ready for some extended rockers, an idea i can't deny i have blatantly stolen from Goosesdad's absolutely fantastic build. The end of the metal work stage is in sight! Cheers, guys.