Big update for tonight on all the work it took to get my wheels and tires to fit.

For reference, my wheels are 18x10.5" Weld S71s with a 6.6" backspace on all 4 corners. The tires are 315/30ZR18 BFG Rival S 1.5. I did my fitting with a small 1/4" thick spacer in the front.

EDIT: I am also running a front brake upgrade that replaces the stock rotor / hub 1-piece assembly with a separate hub and rotor. This adds an additional width to the track the thickness of the rotor flange. Mine are Corvette C6 Z51 rotors, and I can get an exact thickness for someone if they need it.

My ultimate goal is to be able to drive this car without any compromises... so not having to go around speed bumps, avoid railroad crossings or have a huge turning circle. I want to be able to toss the keys to someone and not have to give a long list of things to worry about. A big part of this is doing your homework when installing new wheels to make sure nothing is going to rub or worse... cut a tire! With all of the autocrossing and road racing I am planning on doing with this car, I spent a lot of time here massaging everything to make sure I don't have to worry about tire rubbing.

I will start with the fronts. I removed the sway bar, front springs and the bump stops so I could cycle the suspension through it's full travel.

Here is where I would like my ride height to be:

This is where I expect the suspension to be at full compression (maybe a bit higher):

In just moving the wheel straight up, there were 2 areas that needed to be addressed.

The first was rolling the fenders. There was no way around this. I considered using the old school wooden baseball bat method, but ended up finding a fender roller on Amazon for about $40 so I just on it. The tool turned out to be pretty nice and worked like a charm. The tape was my guide for the area I needed to roll.

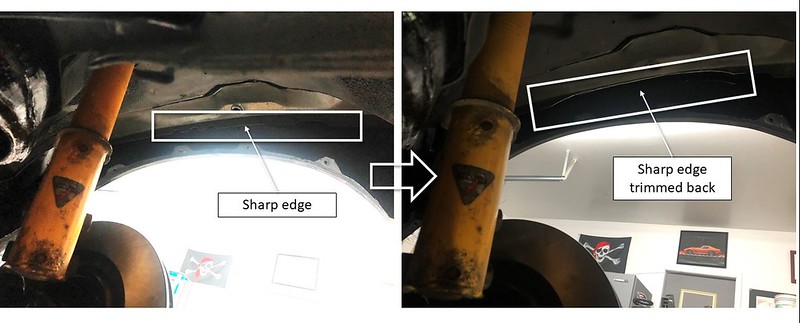

Next I trimmed a bit of material away from the pinch weld where the outer and inner fenders come together. If the tire were to get up into the fender well, this edge would definitely puncture a tire. I tried to get some good pictures but it was tough:

After the vertical clearance was taken care of, I started turning the wheels lock to lock at different areas of the suspension travel (from full compression to full droop) and adding clearance or removing material where needed. All of the pictures below are from the passenger side so just mirror things for the driver's side (except the battery box, obviously).

Here is another look at the battery box interference from lying under the car:

And with the final cut made:

I don't currently have a welder, so once I get the car driving I'll have to find someone to weld up that corner with a little patch piece for me.

After, that things looked pretty good, so I painted to wheel wells and double checked everything:

The real test will come once I get out on the road but for now I'm pretty confident I've done my homework and will be OK. I'll post up the mods I did in the back next.