My dilemma began with "unsatisfactory" accuracy and setup time for 45* miter cuts with my little Jet horizontal 1/2" x 64.5" blade bandsaw.

Cuts for auto related projects are tolerable but for my frame and other projects the time spent hand fitting joints is a PITA.

The current saw and space restrictions:

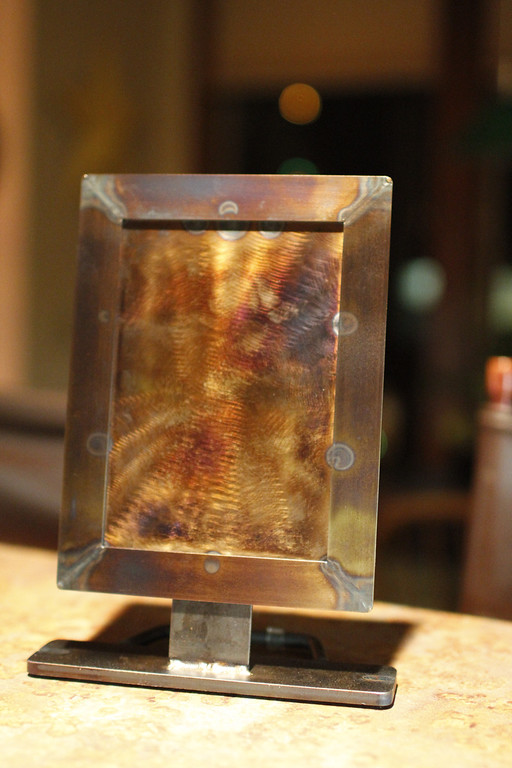

Couple mitering projects:

I started thinking a 110V Cold Saw in the 11" range that cuts 45* both Left and Right would be ideal for speed and accuracy. Not inexpensive upfront and a proper selection of blades adds to the cost.

This is the cold saw:

http://metal.baileighindustrial.com/...ldsaw-cs-275eu

Are the cold saws that accurate?

Do they produce really clean burr free cuts?

Are they low or high maintenance?

Do they work well on smaller tubing and shapes?

I'm close to pulling the trigger and I'm now assessing my wants vs overall needs. Is there a more universal saw better suited to my hobbyist needs?

Would a mitering bandsaw with a 3/4" blade that also goes vertical (a feature I use a lot) be a better purchase in the long run?

This is the bandsaw:

http://metal.baileighindustrial.com/...d-saw-bs-712ms

Will the 3/4" vs. 1/2" blade improve the cutting accuracy?

The upgraded bandsaw would only take a little more existing space vs. adding the cold saw to the mix which requires another 3' x 3'.

Do I want the cold saw.........hell yes! Because I think they're a cool tool and I've always appreciated the quality good tools deliver.

I ask those with experience.........will I be disappointed?

Are the cold saws as frequent a "go-to" tool in the shop as a good bandsaw?