continued below

LS ENGINE IN, NEW TRANS CROSSMEMBER

Around March of 2020 we had the crossmember mocked up, room for the front 18x11" wheels (see above), and it was time to test an LS engine and the manual transmission. For reasons I cannot get into yet I

cannot discuss or show the transmission we are using. All will be revealed at a later date.

The AJE crossmember came with block side mounts, bushings and standoffs on the subframe for an LS engine. I was skeptical that we would end up using their mounts or engine location, but we figured we'd give it a test fit.

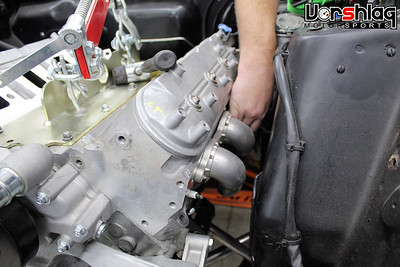

The block side plates are pretty basic but we made them work. The mock-up GEN III LS engine we had on hand was fitted with G8 / CTS-V accessories, minus the power steering pump. We were still unsure if we'd convert this car to electric steering at this point (we decided against that later - other things started to "scope creep" so we pulled this back).

This isn't our first LS swap and we had engine swap long tube headers on hand from 5 different kits we sell, plus a few others, to test in the '67. We had several oil pans, including this one from "Summit" that has a kick out sump, trap doors, etc. We have used this pan on two other LS swap builds lately and it should work well for road course use with an LS, along with an Accusump. We tried a mid-length header first, and it didn't fit either side.

Then we tried this 1-7/8" long tube design from another swap, and it just fell right in. My wife Amy put in the passenger side and Evan the driver's side. These long tubes fit extremely well, as did the transmission, so we stopped to lock down the AJE crossmember location. I was pretty dang happy at this point - no new custom header design would be needed! FOR THE FIRST TIME EVER we already had an LS swap long tube header that could work on a completely different chassis. This never happens.

FINAL MOUNT AJE CROSSMEMBER

After the subframe was mocked up, and after positive testing and measurements with the LS engine and trans in the position set by the AJE mounts, we had a plan in place. We had test fit three LS oil pans, several intake manifolds, and fitted one of our long tube LS swap headers. The transmission we were using fit the factory shifter hole pretty well, too.

We had already adjusted the engine up and down, moved it front to back, and the only thing it did was add a lot of work - virtually no benefits. The Holley Hi Ram intake (below left) was never going to fit no matter the placement, so that tall intake was axed. And honestly it would be massive overkill for the modest 450-500 whp goal the customer had in mind. For a 2600 pound car that is going to be PLENTY of power - I suspect close to double what it came in here with.

So we left the mounts that AJE added to the subframe alone, had our front axle centerline set, and even some progress on the control arms for our custom S197 front strut / spindle / brake setup. It was time to lock down the subframe position and bolt it to the frame.

The K-member had been clamped in place for the previous tests and we had several inches of fore-aft adjustment room, but we locked it down in the position recommended by AJE. Evan marked the holes (above left) then dropped the K-member and drilled through the frame. The AJE kit comes with crush sleeves which were added and TIG welded into the frame holes (above right).

The holes / sleeves were fully welded and then sprayed with self etching primer, then the K-member was finally bolted in place. The mock up LS engine, the Summit oil pan, our long tube 1-7/8" stainless headers, and the transmission were reinstalled March 5th, 2020, right as we started to scale down hours in the shop during the lock down.

Again, apologies for the redacted images I have to use here. Getting the K-member in and the drive train installed was a good step - now we started talking about an affordable stroker 383" LS for this car, which we were putting together at HorsePower Research. We had two other track cars getting similar engines and felt it would fit the power goals, track reliability, and budget allocated to this part of the project.

CONTROL ARMS AND TRANS CROSSMEMBER BUILT

It was difficult to show the work to our customer but these images worked, and in person he could see that the transmission was appropriate for this tunnel size, the power output goals, RPM range, and both street and road course use. Again, will talk more about this when the NDA is lifted.

The crossmember is pretty basic, with a short span to support. We utilized a captured polyurethane Energy Suspension bushing which we have used on many LS swaps. The parts were designed in SolidWorks and cut on our CNC plasma table, as were the control arms shown below.

continued below