OK, so on all the forums all i hear is how great the Mastercool tool is for flaring SS lines. Sure the unit is expensive, but everyone says its great, and they wont use another tool.

So lets see what kind of results you guys are getting, I went out and tooled up for some 3/16 inverted flare work. I'm using 3/16 304L .028 wall seamless tubing.

However i just cant seem to get what looks like a good flare.

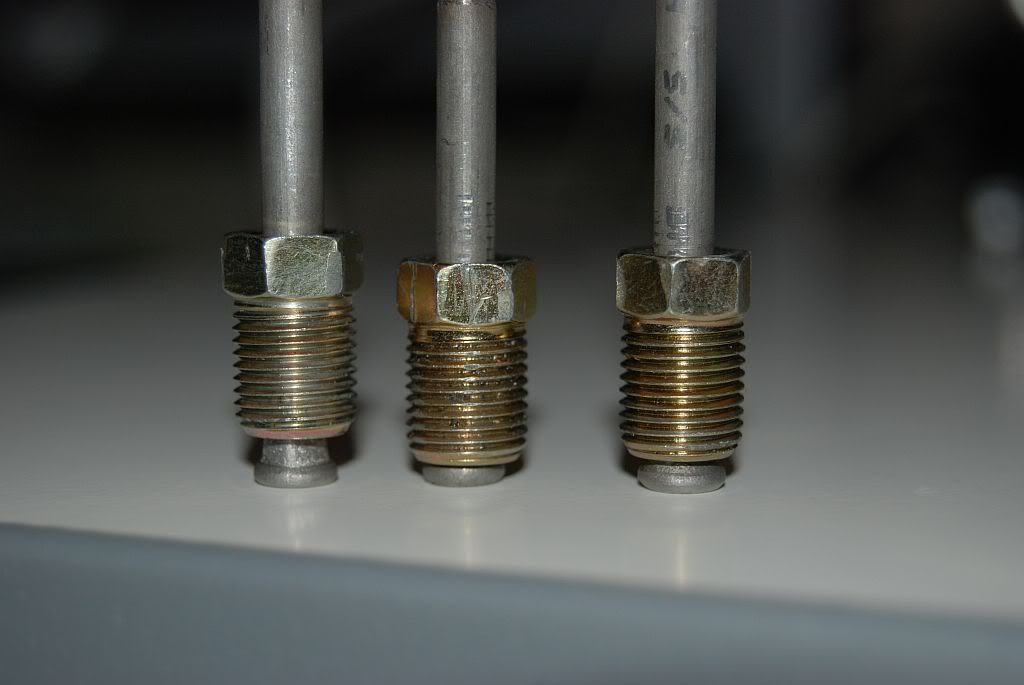

Here are 3 examples,

My next option is to build some type of system that will allow me to test them at 1000psi