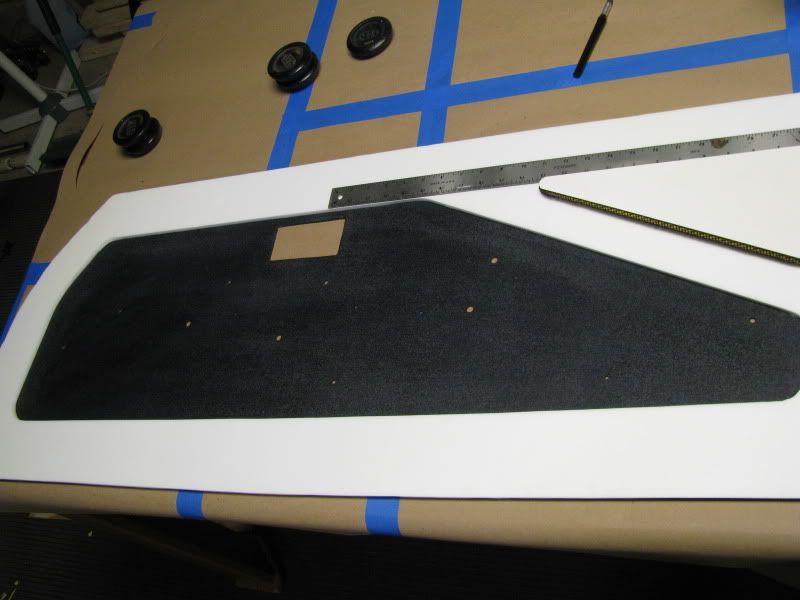

To make things much easier after the glues is sprayed, I taped off all of the places on the panels that I did NOT want glue to be.

The foam used for the main panel was 1/4" closed cell foam. I laid the main panel on the foam and cut around the ABS panel using an Exacto knife. I cannot stress enough, to ALWAYS use a fresh blade in the knife when cutting the foam or you will just end up tearing the foam. It also leaves a very nice clean edge on the foam.

I scuffed the prerimiter of the panel with the sandpaper prior to gluing. Sprayed the glue on the panel and the back side of the foam, let it sit the required 2-3 minutes till tackless and carefully placed it on the panel. I got a huge pile of 2'x3' pile of kraft paper from work that's used as packing material. I used it to cover may work table and a lot of it came in handy for gluing. In this case I put it in between the ABS panel and the foam. Once the 2 glued surfaces touch each other, you are pretty much committed!!!! I perfectly positioned the insert panel over the glued foam and cut around the perimeter. I then removed the foam that was where the insert panel would be. You can see how handy that tape was for covering the area that didn't need glue.

It would seem that these pictures are out of sequence but I learned as I went. As a result, in my haste of removing the tape in the above pics, I had to replace it in the pic below!! I cut the material oversized to be able to wrap around to the back of the panel. Sprayed the glue on the foam surface and the back of the material and waited for it to setup. After it goes tackless you can the start smoothing the material carefully with your hand making sure not to press too hard.

Here is the whole process again. 1- First place the piece to be covered on the foam and cut around the perimieter of the piece........

2-Scuff the surface of the ABS to be glued, wipe clean, spray both pieces with glue, wait 2-3 minutes until the glue is tackless. If it's wet or tacky it's NOT ready.....

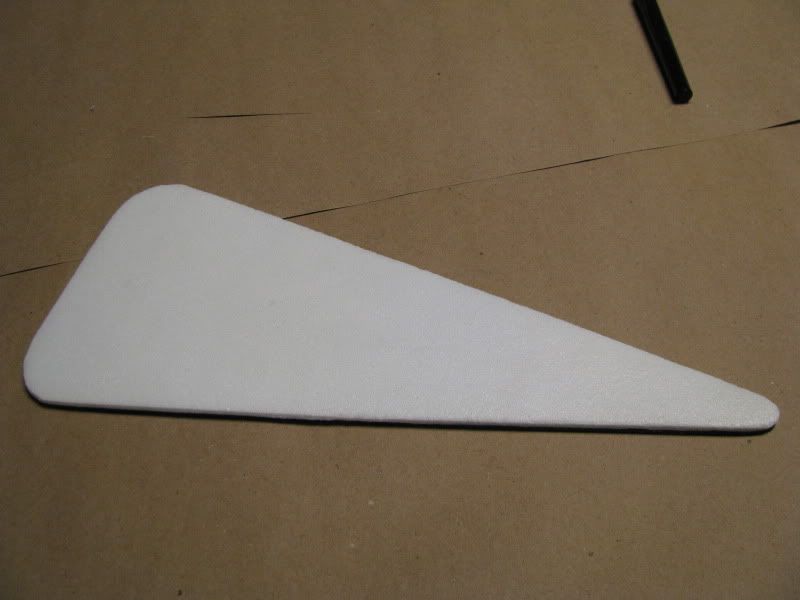

Ready to be covered with material........

3-Cut your material oversized, large enough to have the material wrap around to the back side of the piece to be covered, after the material is glued in place on the front side of the piece, this will be the view of the next step

4-Spray the overlap edge of the material and the backside of the panel with glue, and let it setup.........

As you will notice this is a different piece......... when you are doing this you will find that you DON'T have time to sit there and take pictures!!! So this shows the material that will cover the piece and the ABS panel already with the closed cell foam glued to it, waiting for the glue to set.......