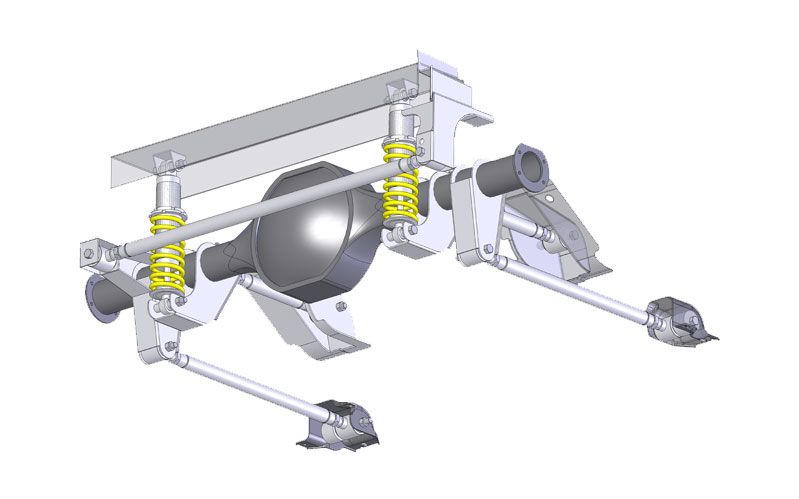

While we wait for all the new steel to arrive the V8TV crew has been working on things like installing the Detroit Speed QUADRALink brackets to our Currie 9 inch rear axle housing.

John started by first building a clever welding fixture to make this job and future ones like it easier.

Instead of temporarily welding the housing to a table he made a fixture that allows the axle to be supported anywhere along its length and that allows the axle to be rotated making angle adjustments and full perimeter welding easier.

The DSE brackets come like the one in this picture. When being installed on a housing that already has the axle tube ends welded on (like ours does), the brackets have to first be cut since they can not be slid on from the ends.

In this pic you can see how John tacked some of the cut brackets on in their appropriate places assuring the right pinion angle recommended by DSE.

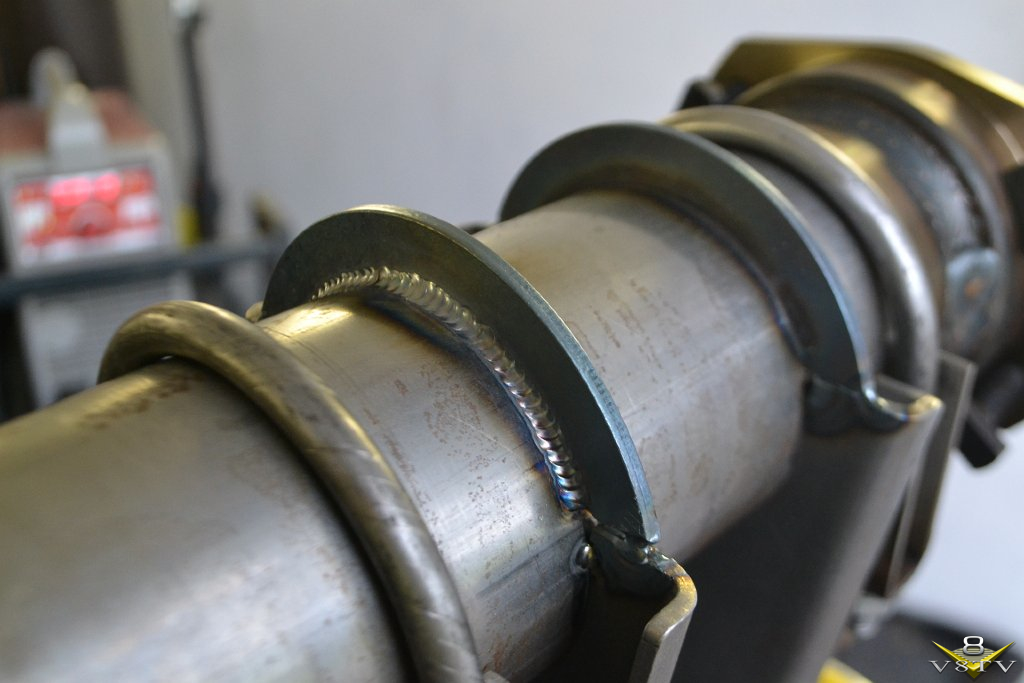

Next he welded the rest of the bracket rings on.

Look at John's welds.

Like the rest of the V8TV crew, he is a true craftsman.

Perfect.

Currie welds their logo onto their housing but it is too wide to place anywhere between the DSE brackets. John removed it and then after the brackets were all in place he welded it back on as shown.

All done except for the addition of some tow hooks, epoxy primer and paint.

Can't wait for the sheet metal to arrive!!!