Project Update September 9th, 2015: This forum post update covers much of the work we did in June and into July of 2015, which includes the bulk of the roll cage design and fabrication. Remember - each picture can be clicked for a larger image (except on some forums, which have weird UBB code).

FIREWALL FABRICATION

A small amount of time was spent here adding some initial tubing and gussets to create a new firewall frame and a bit more trimming of old, unused sheet metal. The new Goodmark reproduction cowl panel was also fitted in place - the goal is to have all of the original lines and exterior panels of a 69 Camaro, and the outer cowl panel is a significant visual piece.

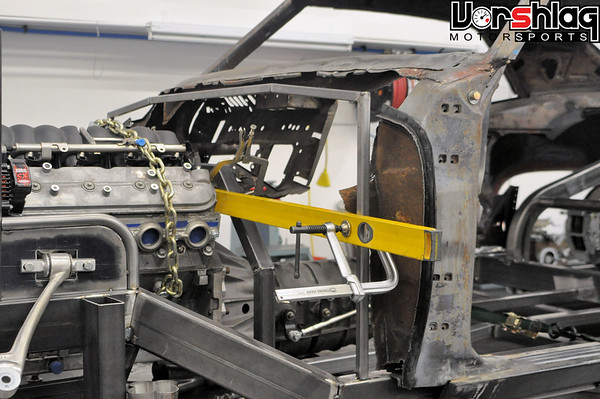

This lower framework will make up the front portion of the transmission tunnel. Access was left for header routing, but a slight change on a component down the road made for some small amount of rework to this frame (you would have to measure it before and after to see the difference).

The reproduction upper cowl panel is fitted to calculate the upper firewall position. This is as far as the cowl will get for now, as that will need to wait for final cage tubing, the tunnel fabrication, the exhaust header construction and some other items that will go in later in the build.

STEERING COLUMN MOCK UP

STEERING COLUMN MOCK UP

Once the new firewall location was picked (after moving the engine rearwards significantly from the OEM placement) a basic framework for the firewall mount for the steering column / bearing was built. The placement of the steering rack was fairly obvious, and the seat mock-up in the last installment showed where the steering wheel needed to end up... connect the dots and that's where the firewall mount for the column needed to be.

Ryan selected a Sweet Manufacturing steering column cage mount clamp kit, which he modified for better strength. This might not be the final clamp we use for the steering column. For now it lets us quickly rotate, raise/lower, and alter the angle of the column to make the final seating arrangement and steering wheel location/angle perfect.

This clamp was completed after parts of the cage (below) were in place - namely, the horizontal "dash bar". Looking from the engine bay you can see that the angle on the bearing/U-joint at the firewall junction was minimized.

BODY & FRAME STRUCTURE WORK

Squaring the body on the chassis was done to ensure the cage layout would be correct and the final body lines would look symmetrical. This took some time, measurements, tweaking, and adjustments.

Some temporary support tubes were added to the window and door frames to add strength while interior panels were cut away piece by piece. We just need the outer skin - everything else is just dead weight that will get in the way of the cage tubes. The final cage structure will add significant rigidity to the overall chassis, so most of the old unibody structure no longer provides meaningful stiffness to a tube framed chassis like this.

These rectangular gussets were added diagonally to join the middle frame and rear frame rails to make the cage layout and load paths work better. The width of the 345mm rear tires pushed the rear frame rails inboard more than you'd normally see on a car like this, so these diagonals help reinforce that offset step in the chassis.

ROLL CAGE COSTS

Building a roll cage for a road course car is a complicated, time consuming job. You have to know the class/rules it is being built for, the construction has to follow the constraints of the chassis you are building it for, there are materials to know how to select correctly and welding techniques to use for various tube and plate junctions. It takes a good bit of skill/experience/technique, proper tools and welders, and when done properly it takes a lot of time.

Lots of people ask us for roll cage quotes, and we usually use $6000 as a starting price for a typical road race cage. That might seem high to some, but even that price rarely covers the materials and our hourly rate. Most times we have to eat about 30-40% of the hours on a fixed bid cage job. Of course some cages cost more, but that's our typical cage cost. I've had trouble explaining the costs to people on the phone so I made a detailed entry about cage costs on our forum and just

send them this link. That post serves as a "tech article" to show why our cages might cost more than others', shows some details on a number of different cage jobs for differing racing classes, etc. Other shop owners have linked to this forum post to help justify their own cage costs - more power to 'em.

ROLL CAGE WORK BEGINS

I sent

that forum post about cages to the 69 Camaro owner as an explanation, early on during our quoting process. And on a build like this, a $5000 cage isn't a huge impact on the bottom line. OK, so where were we? After the main portion of the frame was laid out on the frame table, and the front and rear subframes created and welded to that, the rest of the body went on...

After the body was on the frame, and the first driver's racing seat was in place, Ryan started laying out the roll cage. Jason and I had some initial layout and classing/rules input, but once he got the inner panels out of the way, Ryan went to town and did his thing.

This is a major step in the overall '69 Camaro build, and Ryan was bending, cutting and notching tubes for two weeks on the main portion of the roll cage structure.

The cage tubes are laid out, measured, and bent carefully. Templates are made, strings are run, angles are measured and it is all transferred into tubing. The notching for each tube junction requires math, templates, the right tools, and careful fitting.

It is easy to have a tube droop or rotate slightly in the bender and have the angle thrown off. Ryan sets up guide tubes (see above) to keep the sometimes 10 foot long tubes from slipping or bending downward in the bender, and watches the digital angle finder attached to the tube during each pull.

Accurate measuring, calculation and fitting is key when building a cage that fits this tight to the chassis and body. Here Ryan is adding some tubing that will make up the floor structure and trans tunnel, which I will show in another post.

continued below