Thanks for all the support

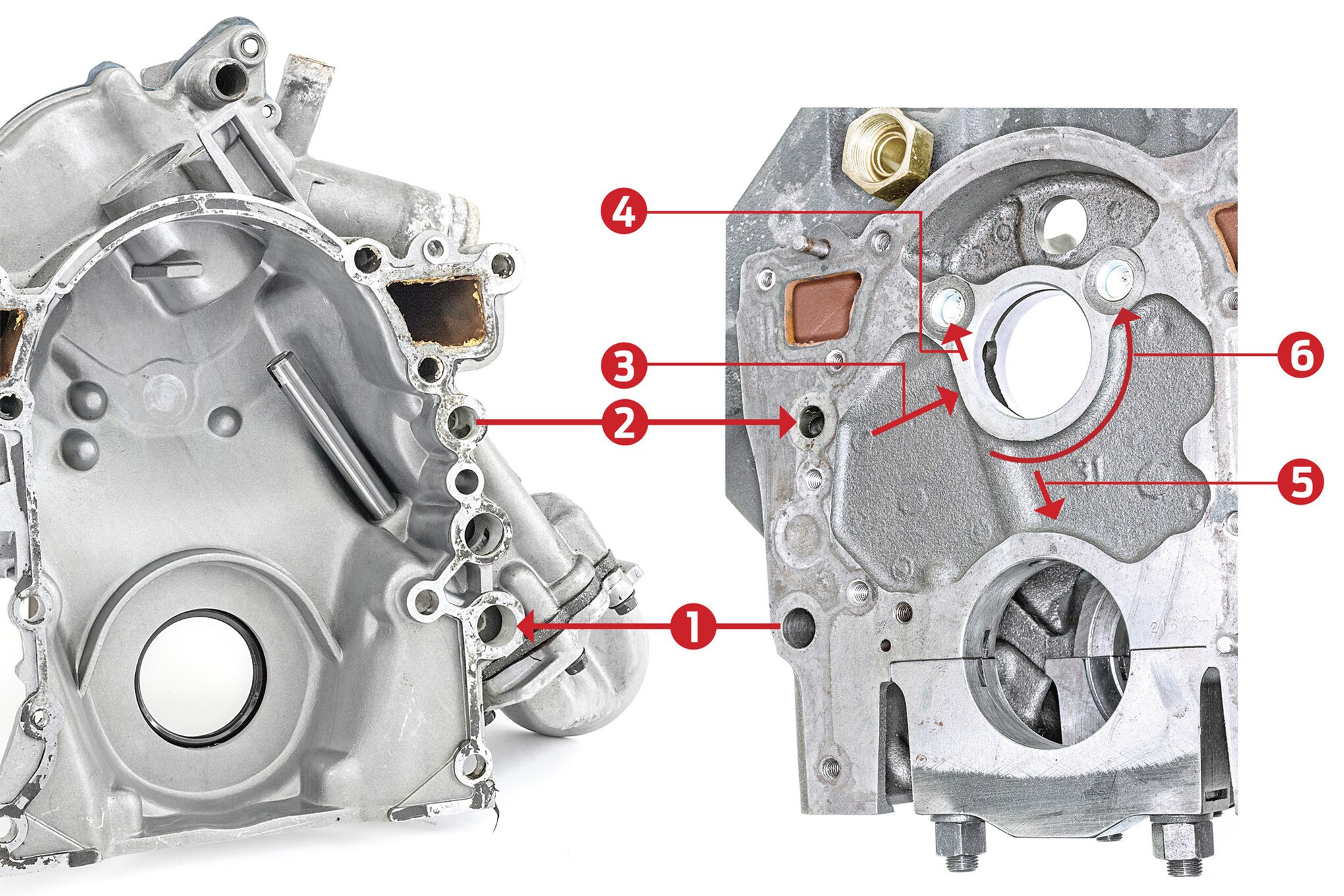

One of the big short comings of almost all Buick engines is the oiling system. The stock setup using steel spur gears riding in an aluminum housing with an aluminum thrust plate that tends to wear. The front cover oiling passages also have a lot of right angles in them so it's a torturous path from the pump to where it needs to go.

Quote:

|

Originally Posted by Hot Rod Pitstop

Seen At Duttweiler Engineering, This Is A Typical 1985 And Later Buick V6 Block And Front Cover. All Buick V6 And V8 Oil Supply Systems Have A Similar Oiling Layout, With The Same Problem: A Tortuous Supply Path With Multiple Right Angle Turns That Make The Engines Hard To Prime And An Undersized, Front Cam Bearing And Journal That Can Fail If It Experiences Oil Starvation—either On A New Start Up, Or If The Car Has Been Sitting For A Long Time. 1] From Pick Up Tube Out To Oil Filter 2] From Oil Pump Into Block Main Oil Feed 3] To Main Oil Distribution Junction 4] To Passenger Side Lifter Gallery 5] To Crank, Main, And Rod Bearing Oil Supply Passages 6] Transfer Groove From Passenger Side To Driver Side Lifter Oil Supply Passage

http://www.hotrod.com/articles/pit-s...t-cam-bearing/ |

Combine this weakness with the fact that the stock oil pump and filter would run smack into the engine cross member I pretty much set out to fix both of those problems in one feel swoop. Now I'm not the first person to do this general idea, there are two others that took other Buick V6 front covers with a gerotor pump and adapted them but as far as I know I'm the only one that did it with a 3800 Series II/III pump which has the slight advantage of being internally located vs. the older pumps relied on the crank snout for the drive gear. However this is even less of a bolt on than the earlier setups they used since a 3800 has a balance shaft and a slightly different front bolt pattern for the timing cover. While it does use the same oil pickup location, the feed to the block is different so I had to change that. I ended up using the lower section of the 3800 cover and the upper section of an Indy Lites dry sump timing cover. I filled the oil return section of the pump up with marine JB weld and then machined a plate that housed the pressure regulator and allowed me to use an AN-10 fitting to route the oil to the external oil filter and then back into the side the of block where the old oil pressure sensor went.

At this point in my life I was stationed at Wright-Patterson AFB in Dayton, OH and I had Ohio George Montgomery do the machine work. When he enlarged the passage for the oil supply he broke though into the water jacket above the oil gallery so he custom machined an insert that he locktited into place with a copper crush washer at the end and an epoxy blob over the top of the breach. He warned me to never tighten that fitting without a backer wrench less it start leaking.

For the upper section I didn't have my mill yet so I literally burned up (it caught on fire) a dremmel hogging out the underside of that dry sump cover and making a spacer bar to take up the space between the inside of the dry sump cover the and outside of the 3800 cover. I filled the rough spots with JB Weld again and then painted the inside with Gyptol and then used Indian Head Form-a-gasket to seal it up. No leaks believe it or not!

Here's a selection of pictures