Dude ----

Okay -- seriously -- I did this just for you after reading your latest post... went to the shed - grabbed my camera - and made up a piece of 3/16" SS tube with a double flare - using my hydraulic MasterCool...

Okay here goes pictorial

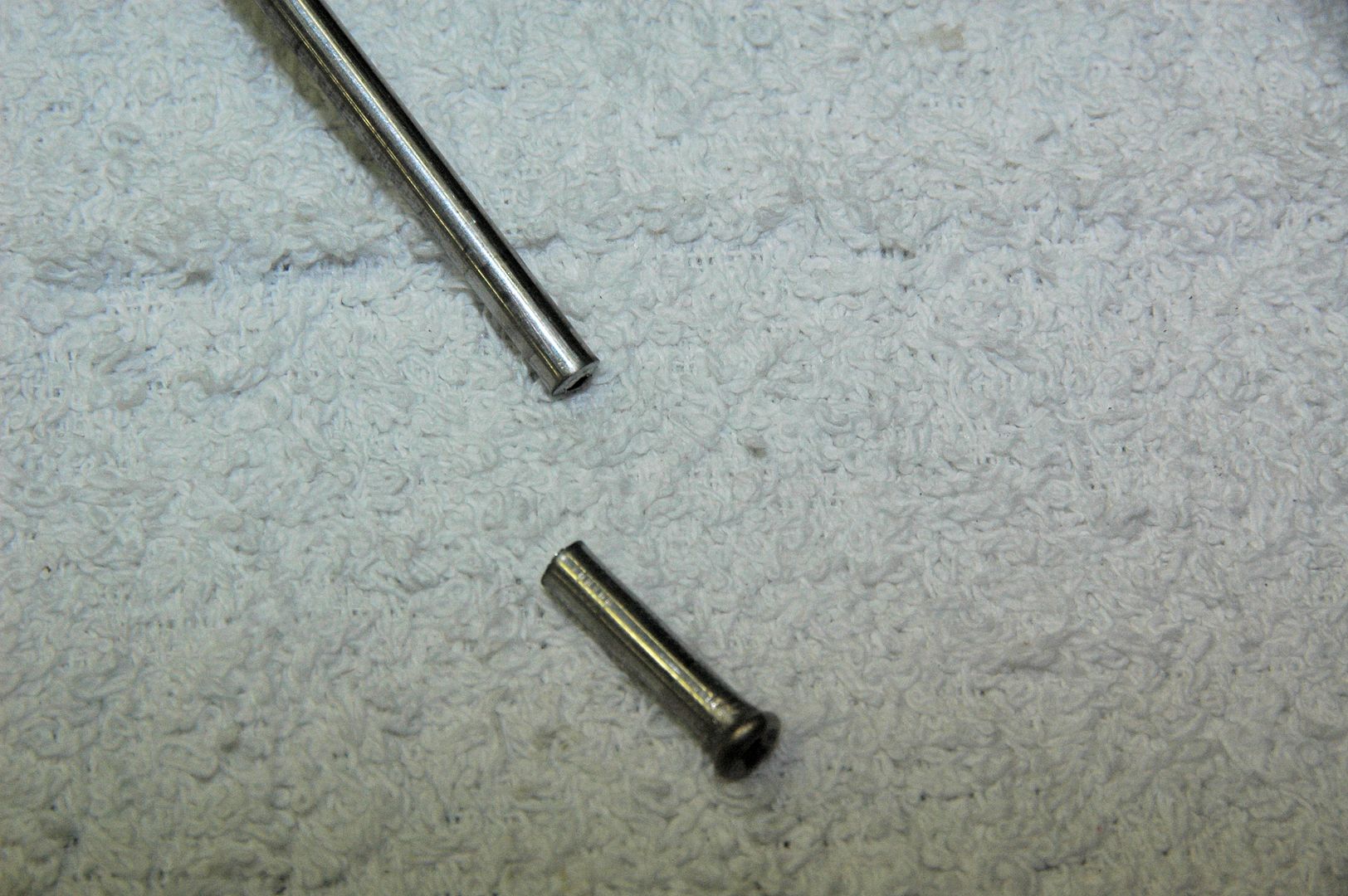

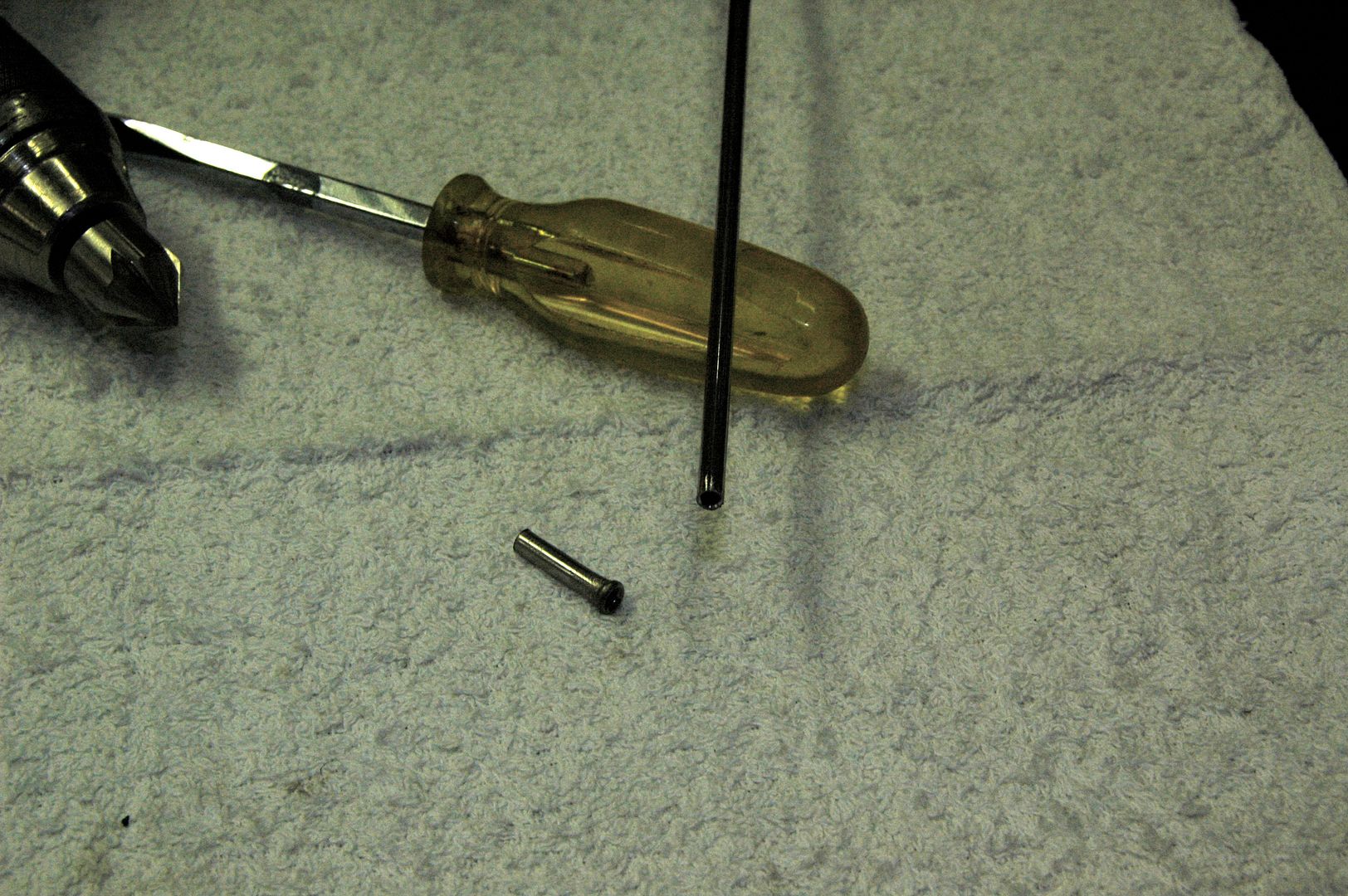

Whacked off a perfectly good flare - for you...

REAMED the inside... you can see the reamer I use on a DeWalt bat drill

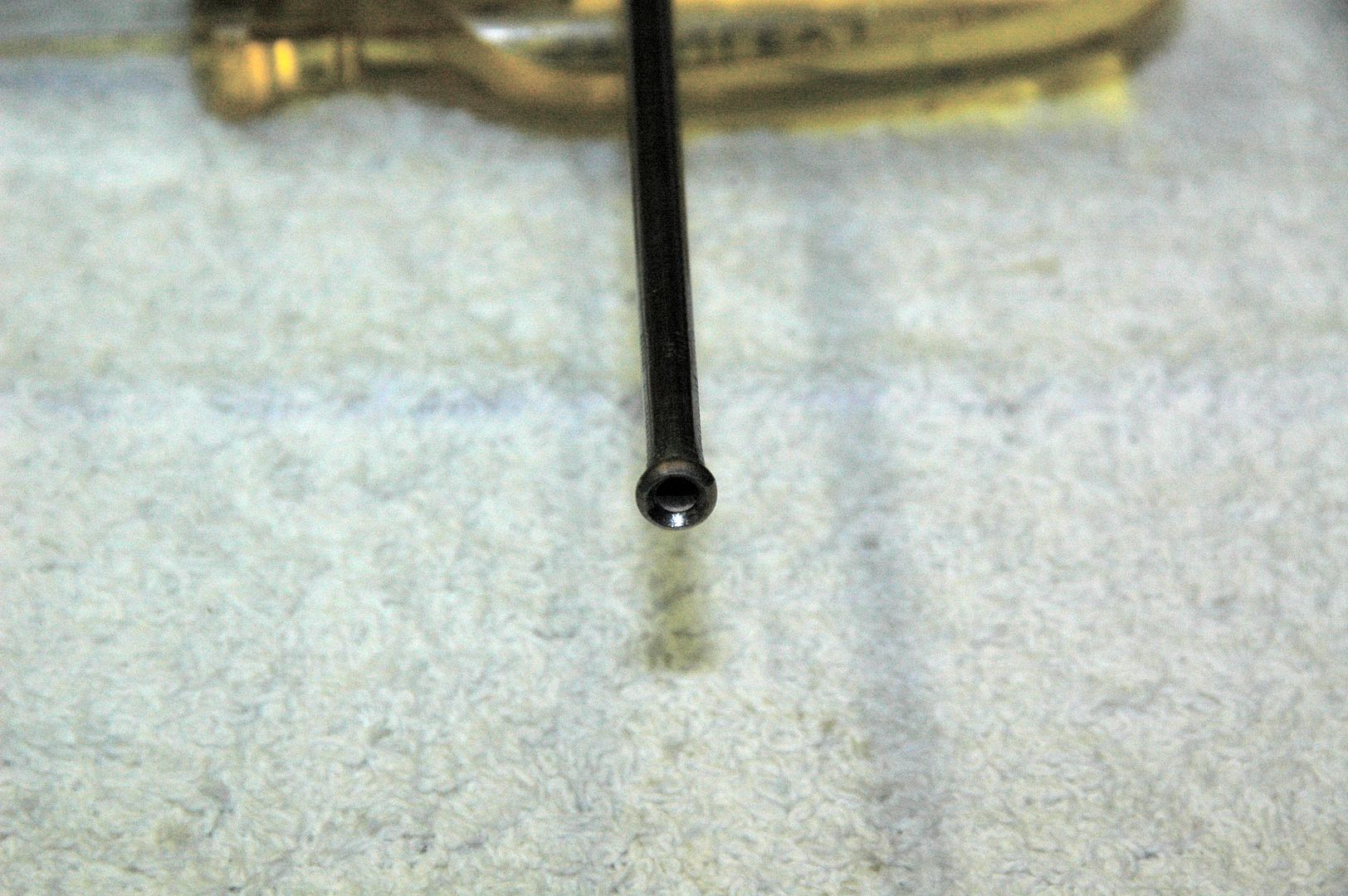

NOTE THE NICE INSIDE REAM JOB...

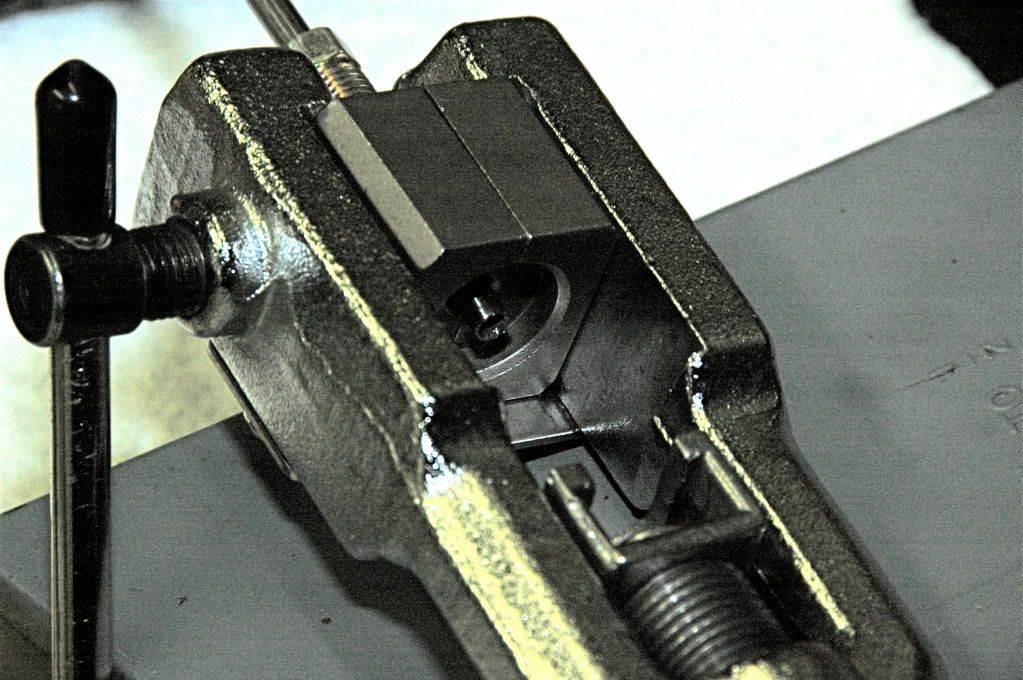

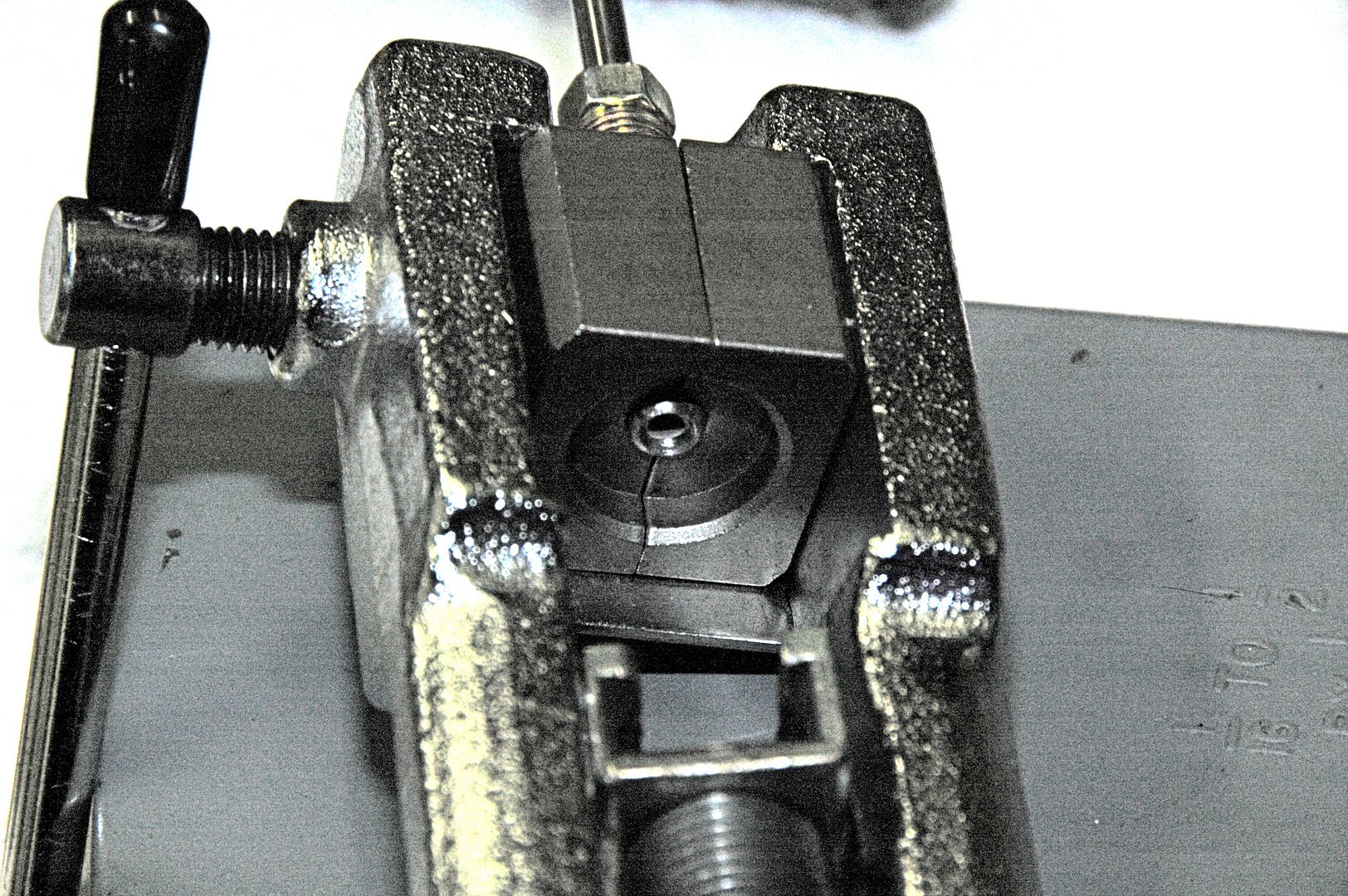

Load the blocks and the tube - the tube needs to be flush with the end of the blocks and the blocks need to be flush and square in their nice little holder... you DO NOT NEED TO GORILLA the blocks to hold the tube - just give her a nice snug... there are plenty of serrations inside the block to hold the tubing with just a little effort....

Done with both operations -- so first the proper die for the first op - then the 45 die to finish - this is what it looks like all done in the blocks. I UNTHREAD the hydraulic --- enough to be able to load the die - then thread the hydraulic until the die is into/touching the tube - then I close the hydraulic valve and squeeze - when she stops - I back off the hydraulic knob - and unthread the hydraulic so I can get the die off/out.

DONE! DUDE -- this just ain't rocket science!

Now it's ready to meet it's fate in one of these little dandy bender dudes...