A little Superbowl Sunday update - I finally picked up some pics from the motor shop and thought I'd throw up some details of my build...

For the most part this motor is not built 7800 rpm top end, but more for fast revving in-n-out of corners torque. My goal was to build a bullet proof (no such thing!) LS7, or at least take out some of the known weaknesses. I started w a flea-bay motor some knucklehead built wrong. I bought it knowing I would tear it down and rebuild it as strong as possible for the planned abuse. Last thing I wanted was a rod grenading the side of the block or needle bearings falling through the rotating assy under power. I wanted it to breathe good, accelerate quick and rev to 7k on the straights. I didn’t sleeve it, although I did speak to RED Steve and one day I’ll beef up the block a little (meaning the motor will be torn down at some point, planned or not).

According to Ovrkill, here’s my ‘puny’ motor (haha, Brent!). All the work was done at QMP Racing in Chatsworth, CA. I’ve known Brad and Mikey for a loooong time and consider them friends. These guys really know their stuff and

everything is done in house. On any given week you’ll see small blocks, big blocks, turbo/blower builds, a Lambo rebuild or one of those Sonny-whats-his-names 800 cu alum motors! That thing is huge BTW…

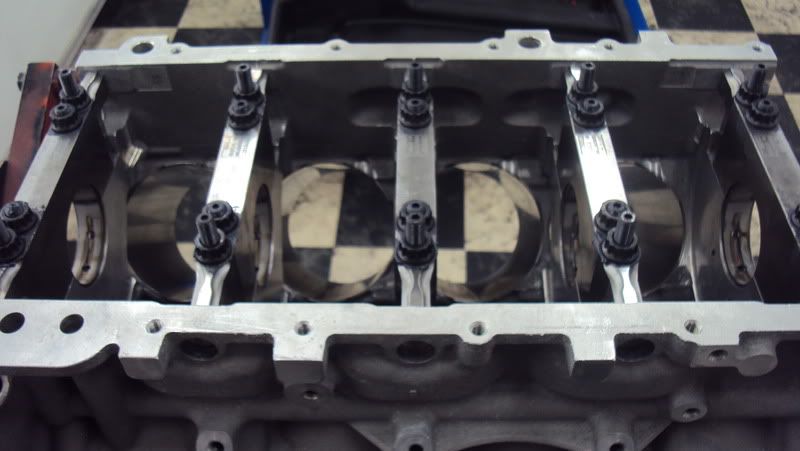

I started w a stock GM LS7 crate motor. Block was CNC blueprinted, diamond honed, decked, align honed, Cam tunnel bored. We balanced the factory forged crank and added Crower billet steel connecting rods, ROSS custom pistons and pins, and a set of Total Seal custom rings. ARP main bearing studs hold it all together. I’ve got a 13 lb Fidanza alum flywheel and a McLeod RST clamp I’ll throw on when the time comes.

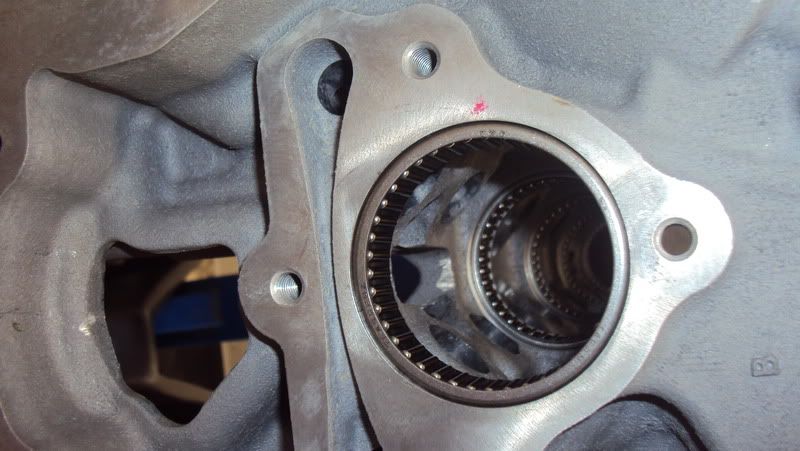

Heads were fully prepped w CNC port to breathe 390 cfm @ .0600. Milled and given QMP's competition valve job. We kept the Titanium valves and added Manley Titanium spring cups , retainers, pushrods and polished valve springs. CHE bushed rockers help delete those pesky needle bearings. We also used some of those new Comp short throw lifters (tray type) to see if they truly help the motor build revs faster and control any valve float.

Tieing the two together is a Comp bump stick. 235/244, 630 lift w a 113+2 LSA. Brad cam doctored it as he always does and this is the formula for my intended use.

For oiling I’m using an LS9 pump, Avaid pan baffle, Peterson baffled tank and breather. These cars don’t quite pull Gs like race prepped Vetts so I think I should be good.

Up top I’ve got a Mamo ported factory intake, Fast rails and a BER ported TB. We threw a set of Fast flow matched injectors pumping 65 psi just in case I decide to add some cubes or something later on down the road.

Here's some some pics...