onward back to metal manipulation

key here is that this is hour 8 but only hour 2 of actual work.

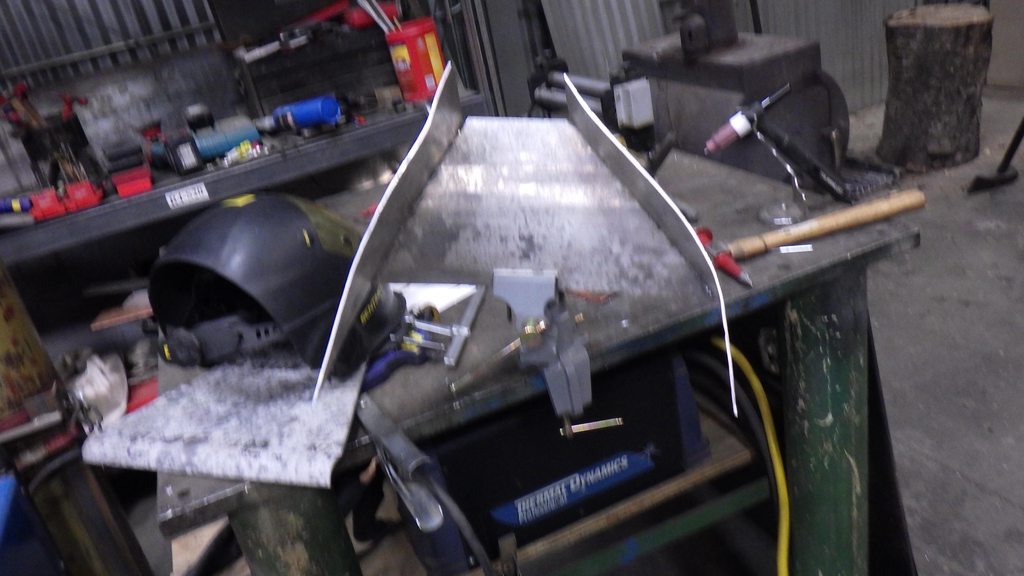

you shall bend to my will

the hardest part was, of course, clamping. With aluminum, adding filler is almost mandatory - so you need at least 3 hands

and unlike steel, there is little memory to the metal, so you can distort it then tap it right back into shape

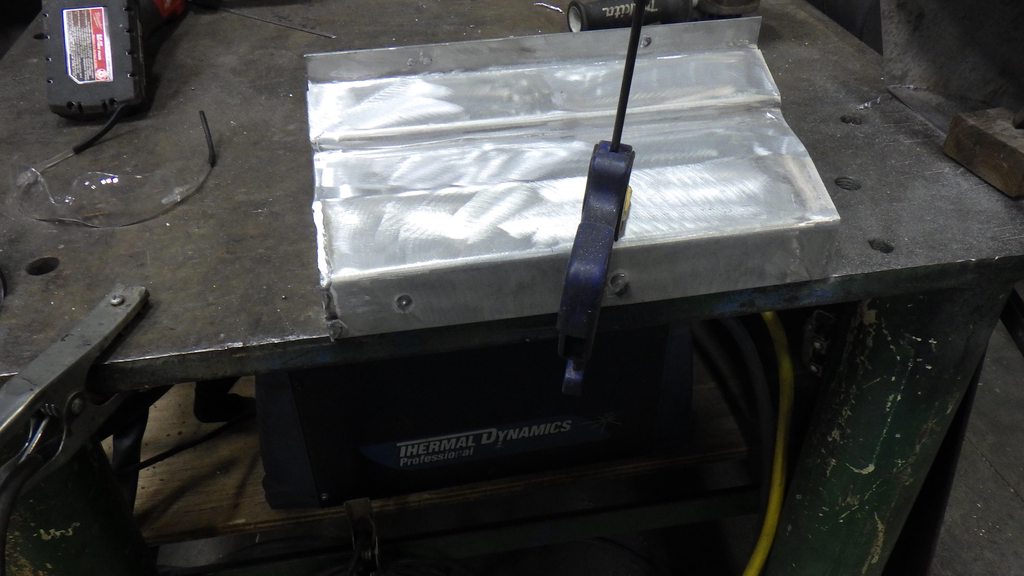

but lord knows there were some ugly welds to get it to stick together

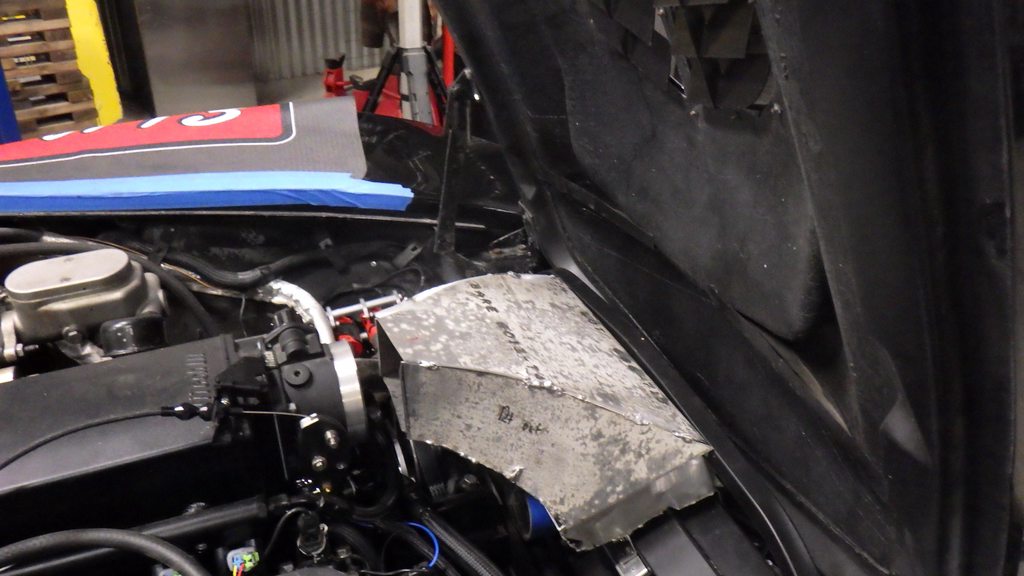

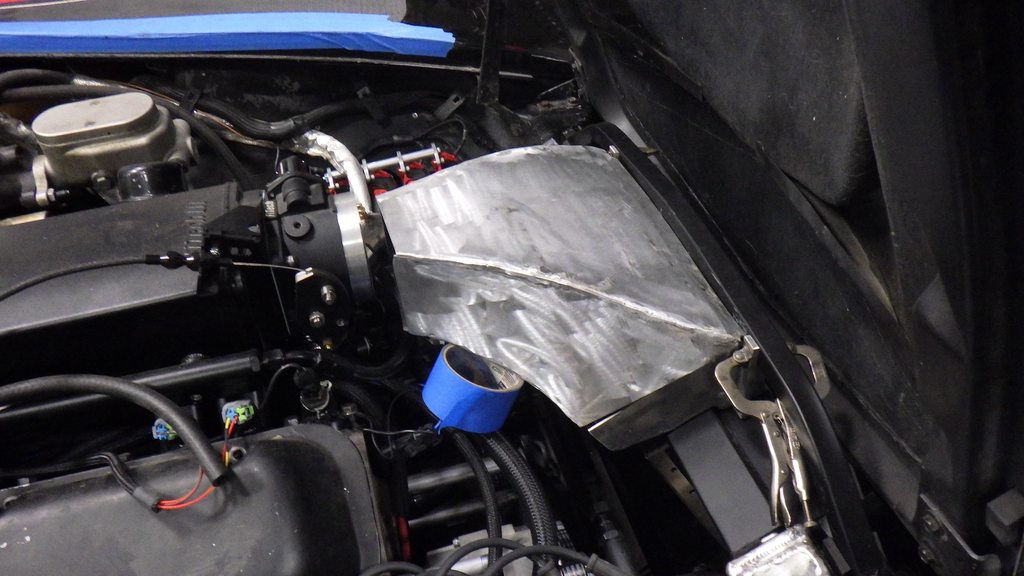

first fit

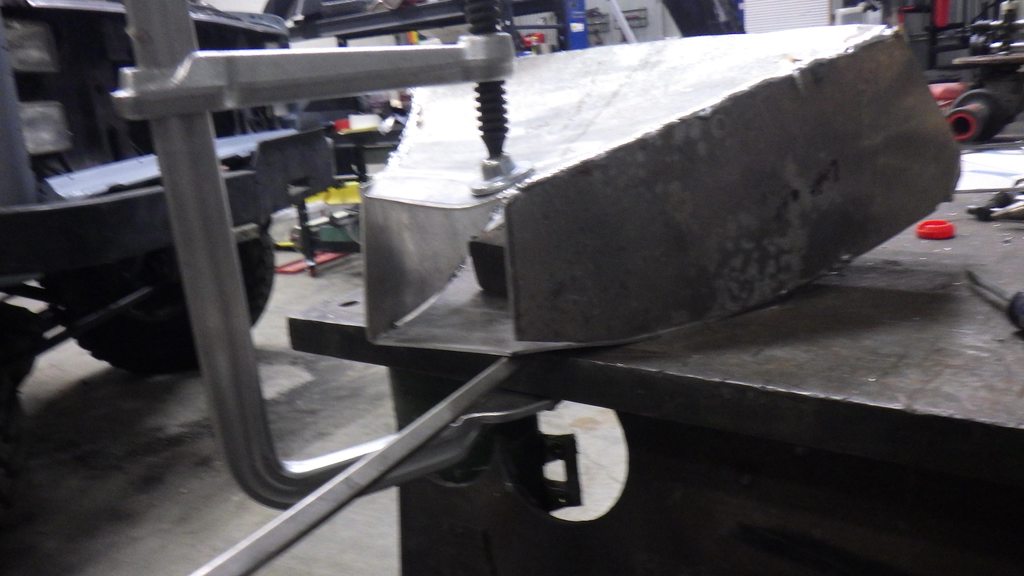

then I needed to work on the pan portion and add flanges

and finish the bottom side

it seems it worked

well, would you look at that

but still, there is quite a bit more work, need to go square to round though I've found that preliminary-finish can help the process

all that work and I'm painting it black..