A couple quick updates: Getting the car ready for USCA at Thunder Hill next month. I finally got my roll bar painted. And who ever told you you can't build your own leaf springs?

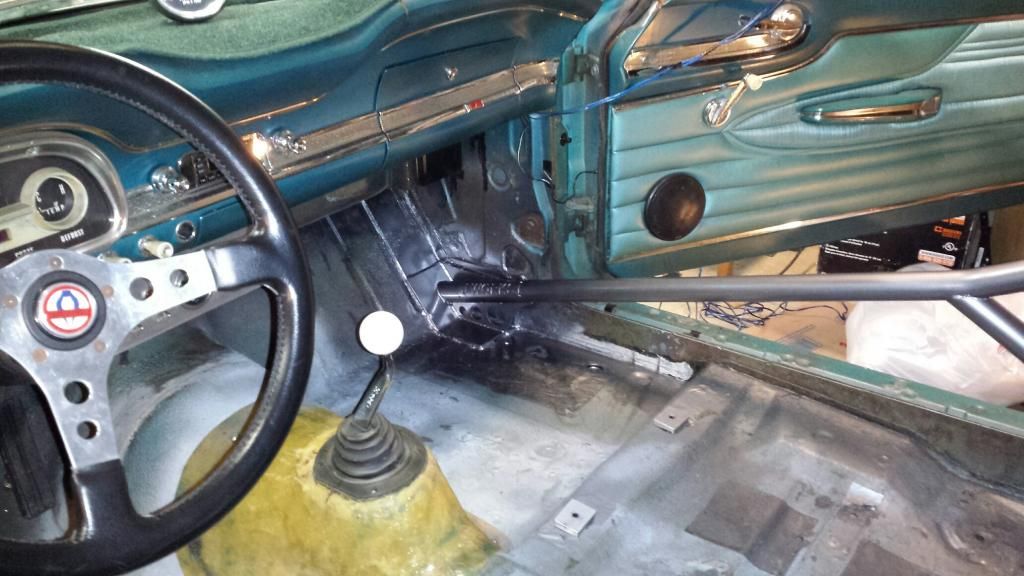

Mike built the cage for me several months back. He did a great job and it is a very tight fit in the interior. I finally got ahead on my "Honey Do" list and pulled the interior back out to spray it before it got too rusty.

I actually modified my leaf packs before the November GoodGuys, but I figured you guys would like to see them anyways. Went from a 155# to about 185#. Really keeps the nose down better (no longer lifts the inside front), but my tires are too shot to get a good idea if it will be any faster.

I added an extra leaf below the main, flipped the old #2, and added a new #3, and an anti-wrap leaf to the front half of the pack.

Formed up a bunch of leaf straps

And had to make a custom aching tool...with adjustable stop.

FYI, McMaster-Carr sells a bunch of thicknesses and widths of 5160 spring stock. As long as you use sharp drills bits, keep it cool and use lots of lube, this stuff drills great.