For the dry sump oil pump I used a NRC 4 stage Pro Series pump. I could have gone with a 3 stage to simplify the plumbing... but the extra scavenge stage creates about 10 inches HG of vacuum in the engine and gives you a little extra HP (about 15 HP in my engine). The 4 stage pump has one pressure section and three scavenge sections.

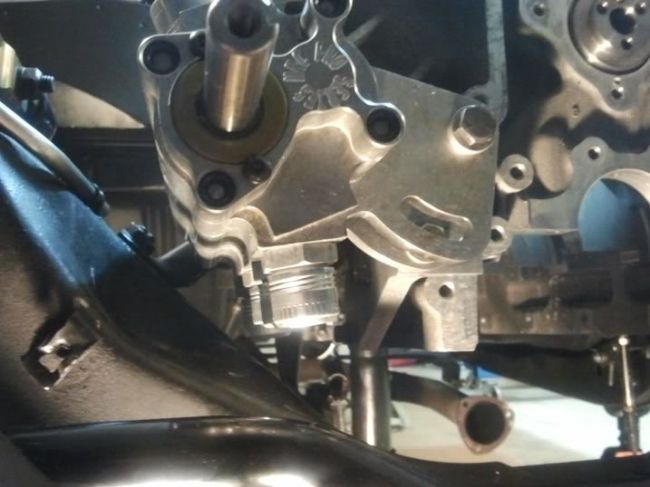

The pump is mounted to my engine block using a billet aluminum mounting bracket that bolts to the factory mount holes on the LS block. I worked with the engine builder to test the mounting bracket before I installed the engine in the car. He made some adjustments to the bracket design until the pump was in the exact right position to clear the sub frame... and allow for adjustment of the cog belt drive.

A.C. loaned me this busted up block to use for testing the fit of the pump and mounting bracket.

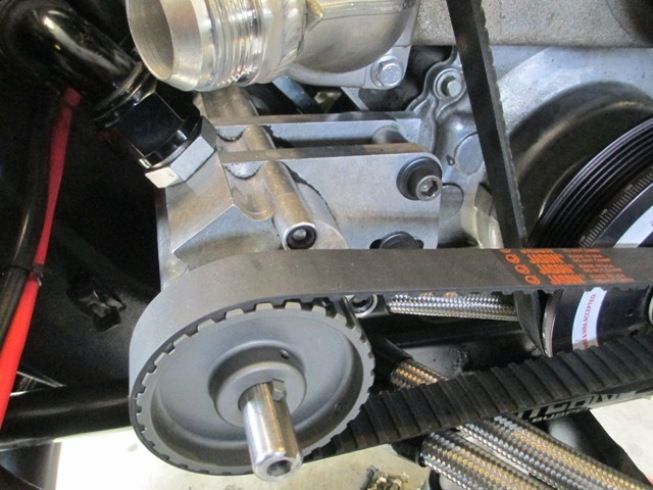

To drive the pump we used a Manley forged crank that had an extended nose designed for mounting the cog pulley.

The pump has a nice rigid mounting bracket.

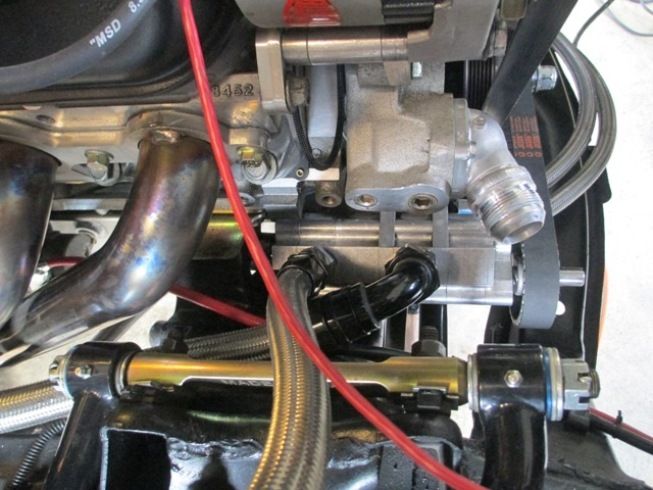

The line on the left is the pressure line and goes into a port at the back of the engine behind the valley cover.

The line on the right is the scavenge return line that goes to the oil tank mounted in the trunk.

For the oil pan the engine builder purchased a Canton pan and then customized it by adding extra clearance for the rod bolts, and adding the 3 scavenge ports.

There is one scavenge port on the right side of the pan and two on the left side.

I'll show all the routing of the plumbing in another post tomorrow.