Quote:

Originally Posted by Peter McMahon

Just read all the way through this, I love it! Seems like you had some blueprint issues? I used to have a 70 Swinger 340 auto so I have always been partial to mopar . Keep at it!

|

Thanks. We'll just say "issues".

Started back on it, time to build headers. Everything about this is going to be a fight for space.

I want the turbo's high enough to drain (don't want to mess with a sump, another pump, check valves, etc), but far enough back to help with weight distribution.

This leaves me very little options for mounting, so a pocket in the firewall is my only option. This will necessitate cold side plumbing in the cowl, and water-to-air intercoolers behind the dash.

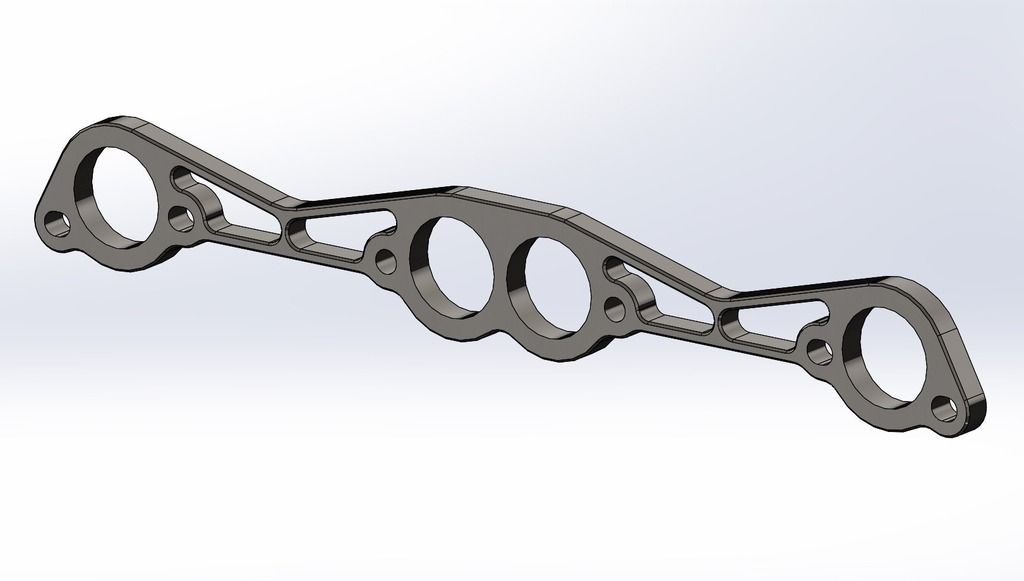

The first hurdle is going to be the long (for a turbo application) tube headers. Okay, second hurdle, first is this is a Mopar that no one makes a flange for. I sent Aaron Oberle the measurements and an idea of how I wanted them and he responded with a very trick file:

Couple of tweaks back and forth and ready to be made. Dropped off some 1/2" 304SS to the water jet guy and got these:

I grabbed my scrap when I picked up the flanges because I had an idea...

This slug is a perfect match to the port profile, and will make a nice forming tool. I reduced it's perimeter by about 0.050" to account for tubing wall thickness, rounded the edge that gets driven into the tube, and polished to keep it from grabbing. Drilled a hole (calibrated eyeball must be off center) and added a handle to have something to beat on!

I formed the tube, slid it in the flange and formed it again: