|

|

04-21-2017, 12:01 PM

|

|

Senior Member

|

|

Join Date: Aug 2012

Location: Bay Area, CA

Posts: 665

Thanks: 4

Thanked 62 Times in 35 Posts

|

|

Will be following this build! Great fab work guys!

Are you going to reuse the factory BMW diff? What gearing?

__________________

Project: 1969 Chevelle, alum 5.3, GTS76 turbo, Chiseled Perf A/W intercooler, Holley Dominator EFI, Davis TC, JRi coilovers, 14" brakes, T56 Magnum. CTS-V Recaro seats!

Coffey Fabrication Nashville, TN doing the fabwork! 800rwhp+/25mpg+/9's@150mph goal  https://lateral-g.net/forums/showthread.php4?t=52976

1993 Mazda FD RX-7

https://lateral-g.net/forums/showthread.php4?t=52976

1993 Mazda FD RX-7, built LS7, T56 Magnum, Holley HP, Davis Tech TC, 8.8" 3.73 Cobra IRS diff, DSS axles, Ohlins coilovers, big brakes.

CCW 18x11 front 315/30/18's and 18x12.5 rear on 335/30/18 RA1's, 2850lbs

10.31@137mph 165mph Shift-Sector 1/2 mile speed

441ci AllPro headed motor and 200lb weigh reduction in the works....

|

04-21-2017, 12:28 PM

|

|

Member

|

|

Join Date: Nov 2009

Location: Dallas, TX

Posts: 22

Thanks: 2

Thanked 0 Times in 0 Posts

|

|

Quote:

Originally Posted by gnx7

...Are you going to reuse the factory BMW diff? What gearing?

|

Nope. For a 450hp build, I'd consider reusing the M3 diff. But with real power and huge sticky tires we wanted a little more strength and better ability to choose a different final drive and limited slip.

So...we ditched the BMW diff and used a combination of Ford parts. Terry will cover all the details and show what it took. There are some tight space constraints under the car that made us do a little more work than we normally do when swapping IRS diffs.

__________________

Jason McDaniel - Vorshlag R&D

|

04-21-2017, 10:43 PM

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Behind the wheel in KCMO

Posts: 363

Thanks: 118

Thanked 40 Times in 37 Posts

|

|

I really enjoy your posts Terry. You spend a LOT of time explaining not only what you guys did but the logic of WHY you did what you did and sharing pictures of the process. I feel there are few that can't learn something to up their game in your threads.

__________________

I build my own junk...

|

04-23-2017, 10:45 AM

|

|

Lateral-g Supporting Member

|

|

Join Date: Nov 2008

Location: Dunwoody, GA

Posts: 6,479

Thanks: 1,028

Thanked 715 Times in 556 Posts

|

|

Great post as usual Terry and Jason. Thanks for keeping us updated on your builds. I love seeing what you guys are working on.

__________________

Trey

Current rides: 2000 BMW 540i/6 and 86 C10.

Former ride: 1979 Trans Am WS6: LT1/T56, Kore 3 C5/6 brakes, BMW 18in rims

|

05-19-2017, 09:28 AM

|

|

Senior Member

|

|

Join Date: Mar 2014

Location: Plano, TX

Posts: 160

Thanks: 6

Thanked 67 Times in 33 Posts

|

|

Project Update - May 18th, 2017: This round we will cover a number of fabrication tasks, including the roll cage and seat mounting. We also did a good bit of work to both the front and rear BMW M3 subframes, modifying and reinforcing them. The rear subframe was also modified to accept a different differential housing (for 8.8" IRS) and the reasons for doing that are explained in detail.

A pair of custom "low profile" inner door panels were built to allow for operational door window glass, which is one of the stock features retained to compete with this car in the Optima Ultimate Street Car series. We talk about concessions needed for Optima as well as the NASA class we are building for at the end. Let's get started.

RACING SEAT CHOICE, MOCK-UP, & MOUNTING

Before we started building the roll cage we needed to pick the seat(s) for this car. This is a critical decision in any race car build, as it needs to fit the driver(s), be comfortable and supportive, and provide the proper level of safety for the class/power/driver. Then it needs to be mounted correctly, safely, and with the right tilt/height/fore-aft placement.

Like with all seat installs we do, we started in our lobby with the customer - test sitting in about a dozen different seat models. We had a number of race cars in the shop with most of these seats also, so he got to sit in them on stands and in cars. We're looking for head placement relative to the halo, shoulder height relative to the harness slots, and width sizing in the shoulder and hips. In the end the car's owner and I both fit the best in the Sparco Circuit II seat (above right). Wait... why does it matter if I fit? Well, I might drive this CSL clone in a few events at his behest. The sacrifices I have to make... :p

Some marketing speak from Sparco: The Circuit LF is an lightweight competition seat specifically designed for road course (ie: circuit) use. Made from aramadic fiber-reinforced fiberglass, the Circuit has an ultra-light shell (LF is for lightweight fiberglass). The integrated head bolsters offer added neck protection and the driver’s legs are also supported well with high side bolsters. The shell is wrapped in an impact-absorbing and fire retardant fabric that helps hold the body in place, with everything meeting FIA approval.

The Circuit "II" version is a more appropriate width for "adult humans" - almost nobody over 100 pounds can fit in the "regular" sized Sparco or Cobra seats (which is why we rarely have them in stock). And the weights published for all seats are always low - I don't think they include the weight of fabric and cushions. Of course we weigh everything, and this halo style racing seat is 24.10 pounds.

Initially we had hoped to use an E46 seat bracket design that was identical to one we fabricated for another E46 race car we are building, shown above right. This beefy bracket is made from tubular and angled steel, is very rigid, and has integral anti-sub-mounts. This "chassis bracket" is made for use with a slider on the driver's side, and is more substantial than the seat brackets used in my TTD classed E46 330, but sit a hair higher. I like this design and might go back and have the 330 brackets replaced with some like this.

At this point the factory lateral seat braces were still tack welded in the floor, and the driver's Sparco racing seat was mounted. We grabbed a similarly sized passenger seat (MOMO) and fixed bracket from another E46 race car and began the roll cage construction around them. The car owner came by for a test fitting, and it was apparent that the seats were going to be too high relative to the roll cage for safe use without a helmet (ie: for the Optima "road rally" event), so we had to go back and re-examine the seat mounting.

We had little choice but to cut out these factory floor seat risers. This was a tedious task - cutting dozens of spot welds - but it gained the room we needed to make a cage that was safe enough for limited street use without a helmet. Lowering the seat like this normally isn't needed for racing use on an E46, but was deemed necessary for the HUGE compromise of running with "a cage on the street" - which is never an ideal situation.

Once those risers were removed there was even room gained by removing one layer of sheet metal from the transmission tunnel - which had two layers with an air gap between then. This extra layer was angled and took up 2" inboard. Removing it centered the seat to the steering column better at the new lower height.

Ryan built a new driver's side bracket that fit the new contours of the remaining E46 floor pan, which were still anything but flat. The two sizes of tubing used were to make the inboard side fit better next to the tunnel.

continued below

|

05-19-2017, 09:29 AM

|

|

Senior Member

|

|

Join Date: Mar 2014

Location: Plano, TX

Posts: 160

Thanks: 6

Thanked 67 Times in 33 Posts

|

|

continued from above

The "feet" are flat steel and there are uprights that are used to clear a big hump in the floor, but the overall structure is still more than 2" lower than before. There will be additional structure added under the car to reinforce the seat mounting points, which will tie into the cage.

Now that picture above shows Ryan in the driver's seat and he's around 6'4" tall - yet his head has massive clearance to the roof and upper cage bars. We kind of went to extreme lengths on this install to gain a massive amount of headroom, and shorter driver's might get a thicker seat pad, but for street use without a helmet its finally deemed safe. Of course we will add SFI padding to all bars around both occupants.

This is the final seat mounting with both Circuit II seats. The driver's side is on a slider but the passenger side is fixed. Both seats are 2+ inches lower than the initial fitment - you can scroll up and see the first mounts that kept the 3" tall seat braces and see how much higher the seats are relative to the roof and upper cage bars.

ROLL CAGE FABRICATION

We talked at length about cages vs roll bars in our last update to our "daily driven track car" project build thread, which is the E46 330 we built and I race in NASA TTD Time Trial class. That car's purpose was to show how far we could go on track in a "street car", and for that build a roll cage wasn't appropriate. It has 245mm Hoosiers and less than 220 whp.

The Optima series does you no favors when it comes to safety allowances, but this V8 powered M3 will have more than TRIPLE the horsepower of our TTD classed 330. It also has giant 345mm Hoosiers for NASA use, big downforce, and a lot more potential for speed and carnage. So on this M3 a cage is not only a good idea, we consider it a requirement.

Obviously some of the cage progress was shown in the seat mounting section above, but that's because the cage and seat mounting go hand-in-hand - another "concurrent" set of tasks that I am splitting apart for clarity. We also showed "considerable interior structure removal" from the back seat bulkhead in the very first project thread update.

Jon, Jason and I all had input with Ryan so that we were all on the same page with respect to class rules and series requirements for the cage material and layout. We chose 1.75" dia x .095" DOM 1018 seamless steel tubing for this cage. The design emphasis was on getting the tubes as far away from the driver as possible - while still keeping roll up door windows for Optima. This would not be a "wheel to wheel" cage (which has more robust door bars and sometimes additional tubes) but a Time Trial car with very limited street use - I go more into the series and classes this car will run at the bottom of this post. We built the cage with those aspects in mind.

After the main hoop was bent up and set in the car the rear downbars were landed in virtually the same spots as the 4-point welded roll bar we added to our shop 330 last month. This M3 cage happened first and I liked the layout so much I asked Ryan to duplicate the back half for my 330 (minus one of the diagonals in the main hoop; the M3 got two).

Many BMW roll cages you see on the interwebs have these rear down bars landing on the shock towers (not doing coilover rear springs, so that's not useful to us here), or into some elaborate jungle gym of triple-triangulated tubes tying into rear subframe mounts (we've already beefed up the subframe mounts) and everything else. With respect to those cage builders, we just don't feel that any of that is necessary on a time trial car. It's just throwing steel at a perceived problem with minimal return. This is a phenomenon we call: Steelitus.

I already know how these "roll cage design" discussions go, and I'm not here to argue with the internet cage experts. I just know what works well for what we have built in various cars and different racing classes. No, we don't have a chassis jig to measure torsional stiffness / frequency (almost nobody on the planet has these types of tools), and we didn't do FEA on the structure, but this cage will be appropriate for the final weight (2600) and type of racing (Time Trial) this car will do.

continued below

|

05-19-2017, 09:34 AM

|

|

Senior Member

|

|

Join Date: Mar 2014

Location: Plano, TX

Posts: 160

Thanks: 6

Thanked 67 Times in 33 Posts

|

|

continued from above

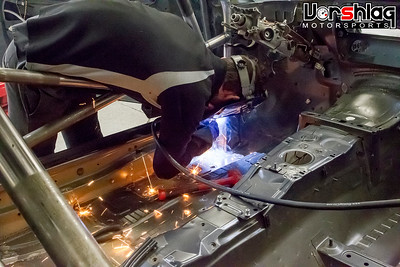

The main hoop was placed behind the driver and aligned closely to the factory B-pillar, placing the tubes just ahead of the back seat floorpan kick-up for the fuel tank. The lower landing points were reinforced with steel plate as well as sitting on top of plinth blocks, to raise the cage up off the floor. In the pictures below you can see the plinth structures (below left) and how the cage was dropped at the front to weld the top joints (below right). Dropping the cage off the plinths allows the cage to be lowered by that distance, to get full 360° welds around each tube. This seems common place, but I cannot count how many cages we've seen done without full welds around all tubes. This is one of those "cost saving" features that often happens on lower cost roll cages. I talk more in depth about "why roll cages cost money" in this forum post.

continued from above

continued from above

Removing the roof panel made the main hoop upper joints a little easier to weld, and we could have done this cage build with the roof installed. Since it was getting a carbon roof to emulate the CSL model and reduce weight, it made it that much easier.

The image below left shows the main hoop being welded to the upper cage bars. Even with the factory roof removed we still needed the plinth blocks on the main hoop landing points to gain enough access for final welding on the top of the cage. The upper door / roof structure panels were still in the way. You can see on the below right picture (with the cage raised up on the plinth blocks in place) the curvature of the upper cage sections and how far up into the roof area they go. More head room, better forward visibility, tighter fitting to the outer panels.

Once the main cage structure was fully welded together the front was raised up on the plinth blocks and they were welded into the chassis (below left). The main hoop was welded to the load spreading plates, which themselves had been welded to the floorpan (below right)

The door bars were a simple "X" style design due to the need for functional door windows. Not ideal, but one of the compromises we had to make for Optima series. We also added a "FIA compliance" bar at the front of the door opening to give more column strength to the side of the cage in the event of a rollover. This is commonly done on road racing cars with high rake windshields and in rally cars. The image below left has the plinth blocks removed, below right has them in place and welded.

With the main sections welded together and to the chassis we looked at additional points to tie the cage into the unibody. The low mounted horizontal bar between the main hoop's lower bars rests right against the rear seat vertical floor section, which was joined to the tub with several stitch welds along this tube. The A-pillar cage bars were also tied to the chassis with some load plates that featured dimple die formed stiffening holes. We may do the same thing at the B-pillars later in the build.

Last but not least, the horizontal harness bar was added after the seat placement was finalized. Ryan added a "taco plate" reinforcement to the X bar joint inside the main hoop.

There's still a few gussets and bits we might add, and some short sections of tube to tie the harness bar into the main "X", but the main part the roll cage is complete. Remember: this isn't the only way to make a roll cage for an E46. This is built as a Time Trial / Optima Street Car competitor, so there are multiple compromises made to meet some conflicting needs.

LOW PROFILE DOOR PANELS

To race in Optima series you can't do door bars like this and keep all the points. Compromises for rules are all part of the game.

To race in Optima series you can't do door bars like this and keep all the points. Compromises for rules are all part of the game.

After we realized we needed to keep the door glass, we knew that we would have to rework the factory door panels - which were just too thick to allow adequate room to the driver's elbow with door bars. We prefer for a race car to have fixed Lexan or no door windows at all, then we can gut the structure inside the doors and push the cage door bars out to the outer skin. This always gives more room to the driver - which is helpful to absorb energy in a side impact (more common in wheel to wheel racing). Optima dings you heavily for not having working door glass, so the X-bar layout on the doors was a concession to that series.

continued below

Last edited by Fair; 05-19-2017 at 09:49 AM.

|

05-19-2017, 09:36 AM

|

|

Senior Member

|

|

Join Date: Mar 2014

Location: Plano, TX

Posts: 160

Thanks: 6

Thanked 67 Times in 33 Posts

|

|

continued from above

We discussed options with the owner and the marked up image (above right) of modified OEM door panels was deemed the right way to go. This allowed us to keep the upper curved plastic section of the factory door panel, which has the inside door handle, a speaker hole, and the upper wiper seals and felts for the door glass. Ryan carefully removed the lower section of the panel, which was plastic riveted to the upper section.

In the images above you can see the detail on the plastic rivets which fastened the two plastic panels together. Once those were cut out he made a cardboard template for the lower section, test fit that to the cage, then transferred the templates to aluminum sheet. These will make for "almost flat" panels, which will gain several inches of width for the cage door bars (removing the "pull" handle and outer arm rest).

With the two aluminum panels cut they were then split along a curved front edge, which would need to be fitted to a curved section of the upper plastic section of the OEM door panel. This gap was filled with more aluminum sheet, then he secured it to the door panel with Clecos and tack welded the pieces together (see below left).

The split sections were fully TIG welded off the car, then the seams were sanded, filled with metal as needed, and shaped for a nice appearance (see above right). The Optima series has car show portions that we cannot ignore, so this work was for those all important "Design & Engineering Points".

The end result adds some necessary protection between the driver's arm and the sharp inner workings of the window glass. It looks good so it should help in the Optima D&E judging, too. We might go back and upholster these aluminum panels, or coat/anodize them in some way. For now we had the clearance needed to get the door bars as far away from the driver's arm while keeping the door windows operational.

FRONT SUBFRAME REINFORCEMENT + SPINDLES REFRESHED

Due to the high torque loads from the 7.7L engine we are building for this car we decided it was worthwhile to reinforce the front subframe while the car was being built. When we are building a car to this level there are very few areas that are "just left stock". The factory front subframe was dropped out of the car and bead blasted down to bare steel.

Once we received the subframe back we inspected it closely for cracks, bent flanges, and any other potential damage. This came out of a Texas car so there were no traces of rust or corrosion, and luckily the motor mount sections weren't cracked. This meant we had a good core to start with.

The factory M3 subframe is a welded steel assembly from a number of stampings, but the factory misses a few spots when they put them together, so those were fully welded by our crew.

They also TIG welded in some reinforcement plates to the underside of the motor mount plate, then a second plate was welded in from underneath to "box" in the bottom of this section. We use one of these mounting holes for our LS swap mounts, so we wanted that as strong as possible. Even the subframe mounting holes were seam welded at both ends, to fill in "skipped" sections from the factory.

continued below

|

05-19-2017, 09:36 AM

|

|

Senior Member

|

|

Join Date: Mar 2014

Location: Plano, TX

Posts: 160

Thanks: 6

Thanked 67 Times in 33 Posts

|

|

continued from above

We were re-using an OEM power steering rack, converted to manual (electric assist) steering, so we also added some tack welds to the back of the steering rack mounts. Once the welding was completed on this and the rear subframe (read more below) it was sent out for powder coating.

There a gloss black powder coating was applied to give this raw steel some corrosion protection. Its a bit flashier than the factory coating, but when you have it down to the raw steel like this, powder coating is the way to go.

The front M3 spindles were also dismantled, glass bead blasted, then "double nickel plated" (a process we tried on a few suspension parts in the past, and it looks great and lasts). The spindles were treated to brand new front hubs, then some of our 90mm wheel studs. We sent the OEM front lower control arms to our friends at SPL Parts for them to model for a billet adjustable lower control arm set with spherical bearings. We should see those soon, but for now the car has the old arms back on to be able to roll around the shop.

8.8" IRS DIFF HOUSING UPGRADE & REAR SUBFRAME REINFORCEMENT

Left: Our E36 LS1 swap "Alpha" build saw tons of abuse on the 188mm BMW diff. Right: Our Beta customer broke the medium case

Left: Our E36 LS1 swap "Alpha" build saw tons of abuse on the 188mm BMW diff. Right: Our Beta customer broke the medium case

The argument for using a BMW diff in our swaps goes back to 2002 when we first starting our E36 LS1 "Alpha" project. And in 2011 when we kicked off the E46 LS1 development we had the discussion again, but this time with many years of first hand experience with a "medium case" E36 M3 limited slip behind a 500 whp engine and 315mm Hoosiers. We couldn't manage to break the 188mm Medium case but we did have one customer (540 whp) that did - but in his own words, he breaks everything.

This LS powered Miata used an aluminum Ford 8.8" IRS differential mounted in a custom rear subframe

This LS powered Miata used an aluminum Ford 8.8" IRS differential mounted in a custom rear subframe

In various V8 builds since then we've used a variety of solutions: the Medium case BMW diff, a Ford 8.8" diff (Miata V8, Beta E36 LS1), and even the 210mm "large case" BMW E46 M3 differential in customer E46 M3 LS swaps. This "large case" BMW unit is also used in heavier cars like the M5, 7 series, and more, and in the E46 M3 it always came with a limited slip differential.

The non-M E46 chassis got the medium case unit, and 100% of those were OPEN differentials, which while still fairly strong are not ideal for putting down power (I fight with the open diff with only 220 hp in my TTD 330). For this project the "easy button" solution would be to leave the E46 M3's larger 210mm ring gear unit in place and just upgrade the axles. And we proposed that to the owner of this car early on - but cautioned that the torque that this somewhat larger stroker LS motor can put out (700 ft-lbs) might be past the limit for this car. There are lots of BMWs running around making "dyno numbers" higher than we're shooting for on the 210mm housing, but I suspect many if not most are not making the torque we will. This will be a brutal track car that will even see some standing start launches (Optima Speed Stop events) on rather wide tires. "Over building" the diff was the smart choice...

continued below

|

05-19-2017, 09:44 AM

|

|

Senior Member

|

|

Join Date: Mar 2014

Location: Plano, TX

Posts: 160

Thanks: 6

Thanked 67 Times in 33 Posts

|

|

continued from above

Here are more weights from the the 1999-03 Mustang Cobra 8.8" aluminum rear housing (62.9 lbs, at left) and the "medium case" BMW E36 housing (76.9 lbs, at right). The weight for the "large case" E46 M3 unit is above, at 100.4 pounds. All of these weights are complete housings with the factory rear covers, factory gears, and factory differential units. The BMW housings are heavier because they are cast steel - which is stronger than aluminum - but what usually breaks is the actual ring gear.

And while the external dimensions on the medium case BMW unit and the Ford 8.8" unit look similar, the 8.8" ring gear translates to 223.5mm. And this is one of those cases where "bigger is better". Not to mention there are countless ring and pinion gear sets available at a fraction of the cost of the limited number of BMW gear ratio options for either the 188mm or 210mm housings. And limited slip units are more abundant (and less costly) for the 8.8" vs the BMW units.

So like the engine and drivetrain in this build, we're looking at a domestic part for a lower cost and stronger differential, with more plentiful gear/diff options and a lighter weight by nearly 37 pounds.

We happened to have an 8.8" aluminum diff housing from a 2015-up Mustang S550 chassis, and its a thing of beauty. We mocked it up next to the 210mm M3 diff (above left) and it looked like it might work. Then we pulled the subframe out of the car, pulled it apart, and bead blasted it to raw steel. That's when we noticed - this S550 housing isn't going to ever fit. The front mounting "feet" on the S550 housing are inside the pick-up points of the rear suspension and the middle of the case hits at the back. This would require a completely scratch built subframe and new control arm lengths - and we don't need those kinds of hassles.

Enter the 1999-04 Ford Mustang Cobra aluminum 8.8" housing. I picked one up used because we couldn't find new stock of the OEM housing or even the old Ford Racing part number kit - popular with Cobra kit car builds for years. The M3 rear subframe was clamped to the fab table and Ryan started cutting...

The front of the 99-03 Cobra 8.8" housing is much narrower than the 2015-up S550 housing, so after some minor clearancing and reinforcement, the front was able to slide between the suspension pick-up points. The front sections needed a good bit of fabrication and even custom machined front mounting bushings, but it all went together smoothly. The centerline of the drive flanges was matched to that of the BMW unit and it was squared up before any of the mounts were designed.

The rear mounting was a bit trickeir. The 99-04 Cobra "clamp" mount was similar to the E46 non-M rear cover, but was never a popular choice and this cover/mount had failures in the Cobra Mustangs (below left). The later Explorer 8.8" rear cover (below right) mimicked the E46 M3 "ears" but they were in the wrong plane fore-aft and the wrong width. It was going to take massive modifications to make that work, so we punted on these.

Instead Jason recommended an aftermarket steel Ford 8.8" solid rear axle cover that has the same bolt pattern and shape as the 99-04 8.8" IRS housing. This was a fabricated unit for off road use, so it was beefier than the thin stamped steel OEM covers used on solid axle 8.8s.

continued below

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 12:20 AM.

|