Making good progress. Finished a fixture and bent up all the brackets. I started tacking them together late this afternoon. I need to practice inside corner joints and learn how to tell how much heat to use.

Turned up a ton of spacers. No CNC here.

Don't try this at home kids. Hanging it way off the mill.

Added some extra roll center adjustment to a down rev part.

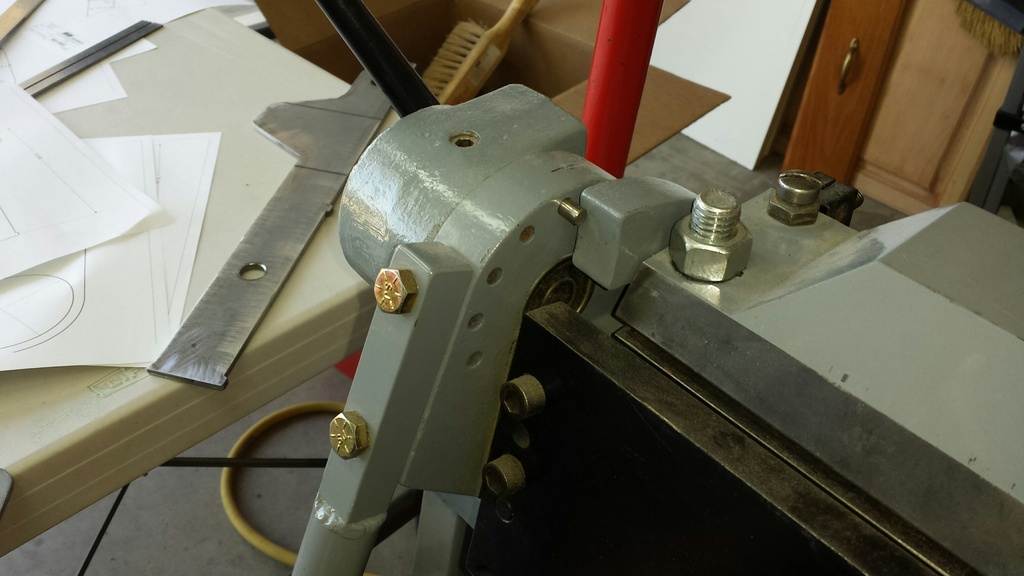

I love my vintage Di-Acro brake. I saved it from the scrap metal guys and restored it several years back.

Its little details like this you could never get in a modern piece.

The dowel pins fit into reamed holes every 15 degrees. There is an additional adjuster screw on the hard stop that will bridge the gap. The result is very repeatable bends. You understand their name, Die Accuracy.

Sometimes you have to get more creative.

Is that 3.5" exhaust tubing for the Falcon?

Table full of parts ready for welding.