I promised pictures.

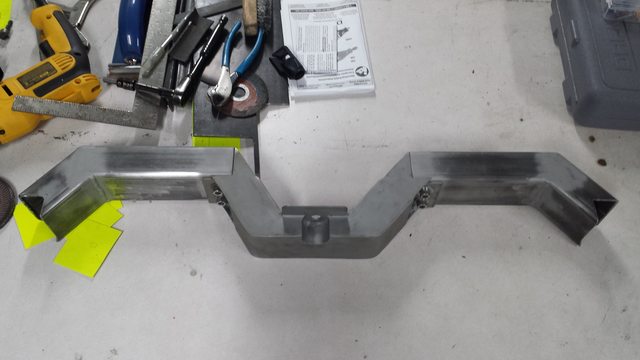

I had to raise the transmission up in order to correct the driveline angle issue I was having, this pushed the exhaust into the transmission cross brace. I could have gone with a better, bolt in design, but I wanted to increase the structural rigidity of the car some more. I also apparently really like to take the longest most difficult path I can take to get the job done. So here's my version of a welded in transmission cross brace.

The center section I put together with sheet metal. The sides are 2x3 tubing. Here it is installed in the car.

I had to replace the front foot wells and the lower parts of the toe boards in the car due to rust. I wanted to make a more rounded tunnel to clear the T56, but this is what I came up with given my limited abilities. It'll be covered by the center console eventually but it also will look good if exposed in my opinion.

Here it is with a lot of the grinding completed. I still have plenty more to go. I'm not fully welded yet either.

Part of what is taking me so long is having never done this before, me moving slowly, and me wanting to do minor stuff like welding the drain plug into the floor because I didn't like the way the floor would look from underneath. Like I said, the long, difficult road.

I also have a lot of gaps I have to fill in. I removed too much metal in places so I have to put it back some how. It's really time consuming but I'll get there.

That's it for now. As I said, I hope to have it back on the ground in a couple months. We'll see what life has to say about that though.

Thanks for looking.