Besides the anticipated tunnel clearance mods the only real issue we had with the install was the throw-out bearing shipped with the kit from Hurst Drivelines......too long

Hurst responded promptly and shipped me a Mcleod adjustable at no charge.

Other than having to cut the tacks on the exhaust system, R&R the tranny and kick my own azz the install went pretty well.

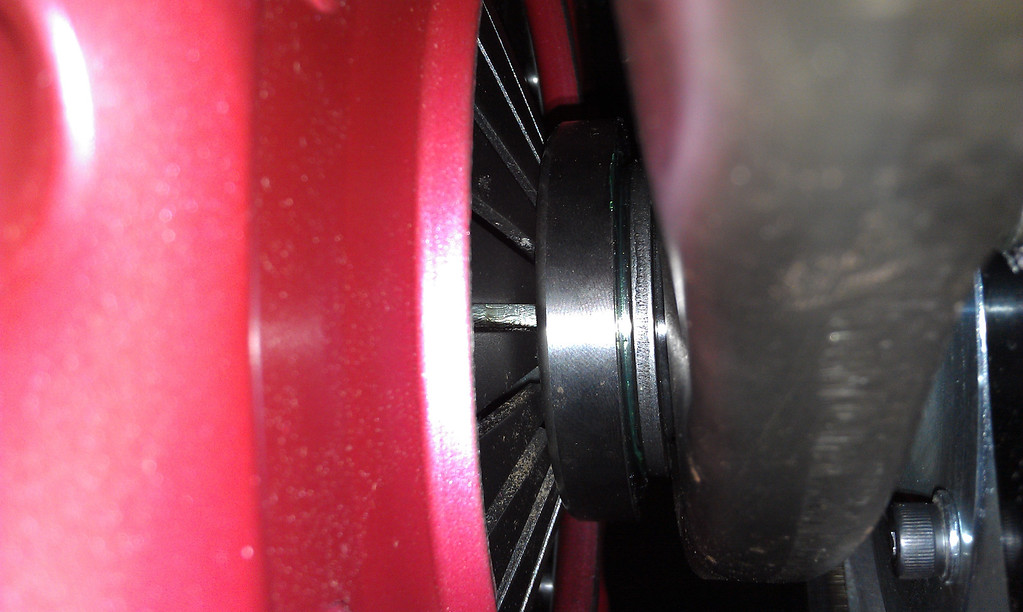

So moving right along, I've fought a leaking front timing cover to oil pan seal since I've had the car. Decided while the tranny was out to replace the cover and pan with Milodon units and a Felpro one piece silcone gasket. We could squeeze the motor up just enough to get the pan out between the crank and cross member. One ficken problem, the windage tray would clear the oil pump pick-up.

Nothing a little cutting can't fix.......I saved the piece so in the future it can be tacked back in.

I used black permagasket silicone on the front and rear seals when we reinstalled the pan and all went well.

So the first test drive I find out it's leaking worse than before.....WTF! I call Milodon and was informed their gasket has a little more material at the front an rear seals than Felpro's.............

So at some point in the near future the motor will be coming out and the pan will be mounted with a Milodon gasket and The Right Stuff. Did I mention that I HATE OIL LEAKS!?