Quick update

My how fast the summer goes! Around the first of this month, I got the quarter panels welded in, and the welds ground down. After this, I fabricated the inner wheel wells to clear my tires.

I then epoxy primered the inside of the trunk, the underside of the back of the car, and the wheel wells, and did the seam sealer. I also applied a layer of uPol Raptor liner to the trunk and the wheel wells.

It's stupid how much time went into those wheel wells, but I can clear a 315 tire if I want, and it won't be tucked so far under the car that it looks funny.

The raptor liner doesn't hide the spotwelds and such as well as I'd hoped, but it still looks good. If I'm worried I'll make a carpet for the trunk.

Made a cover for the shifter linkage access plate... I lost the one I made before. Thank god I keep a journal of my hand sketches for parts made like this.

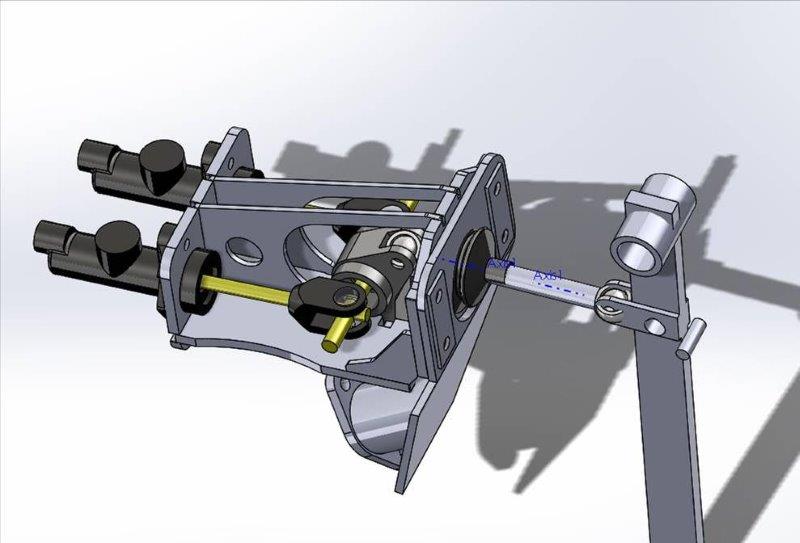

I decided I didn't like the brake booster setup I had. So I bought a Wilwood 60 degree Master Cylinder mount. Turns out I don't like how that fits either. So I made my own housing for the MCs and the bias bar pivot, which puts them somewhere I can live with. I spent a bunch of time changing the design, and ended up with something cool - the pedal ratio is 5.5:1 for the first 1/8-3/16" of MC stroke, so any slack gets taken up quickly. Then the ratio increases to about 6.35:1 at 1/2" of cylinder stroke, and sort of levels off there. I'll be interesting to see how that feels in practice.

All of the parts are at a shop being laser cut now. If you look carefully, you can see little tabs and other interlocking features, that will make fixturing it much easier. I'll take some pics of the finished thing!

I wanted to keep the noise and engine smell out of the cabin, so I found this rubber bellows after scouring every catalog I could find. Next to it is a DSE bracket I modified to hold a Tilton 75 series master cyl for the clutch.

I decided to work on the front fenders, and finish the metal work with them. My plan is to do the front fenders, the door shells, and trunk lid... then send them for sandblasting. This will reduce my time spent getting them that far.

I did NOT expect to find any rust, but figured I should look in the common places. Loand behold! You can see where I welded up some pin holes back in 2003 when I first painted this car. I couldn't tell this was present under the 3M rock chip guard stuff I had along the bottom of the car.

I found some more along the door opening. I had welded up individual pinholes instead of sectioning out the bad metal. Luckily, a wire wheel took the rust off the inside structure, and I was able to primer it.

Patches are welded up. Just need to grind them down! I think these fenders spent some time leaned up against a tree with the top in the mud, as the folded over area at the very top of the panel was a bit soggy. I cut the rust out and made a patch for this. I need to tweak the welds a bit, then I'll fold it over the inner structure, just like new.

Next update: Other fender, doors, trunk lid!