Just had a quick chance to run a couple more beads with the welder set.

These were on power 5-3, gas @ 17 cfm, and wire speed between 3 to 4.25, also experimented with gun angles, push vs. pull, and speed, thus the inconsistencies.

It makes a "little" difference, though the operator still lacks talent.

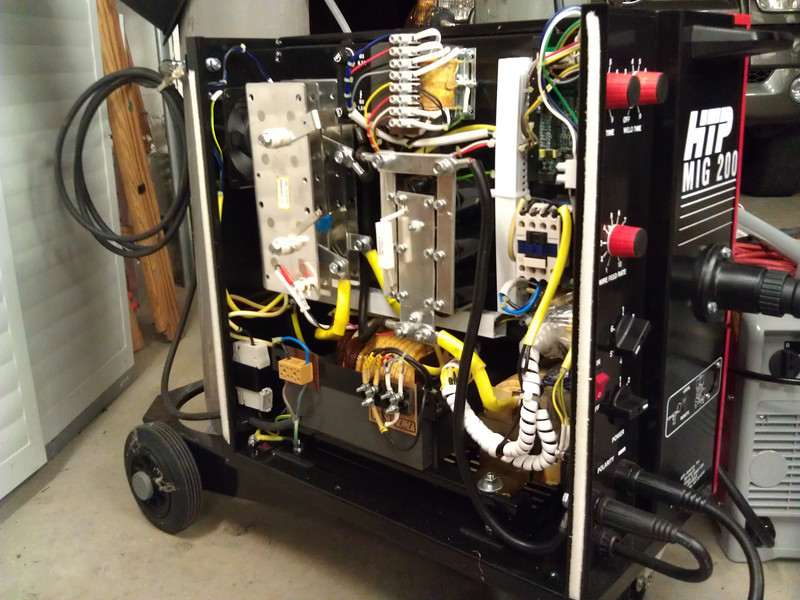

Here's a couple shots of the HTP 200

The sales, service, and after-sales support from HTP / USAWeld.com has been very good. I wouldn't hesitate to recommend them as a viable player against the big two.