So I figure out very quickly that I need all the windows and hardware to fit the door panels. So now that's in a holding pattern waiting on parts. I did check fitment with a seat though and everything fits close, but won't require and mods.

I did get started on a raised floor toe board though to hide my InfinityBox power modules. With the seats set back to match the engine set back it left a ton of foot room, so I'm not losing anything in this area. Plus it helps move weight lower in the car and is easy to get to if I need access to the fuses.

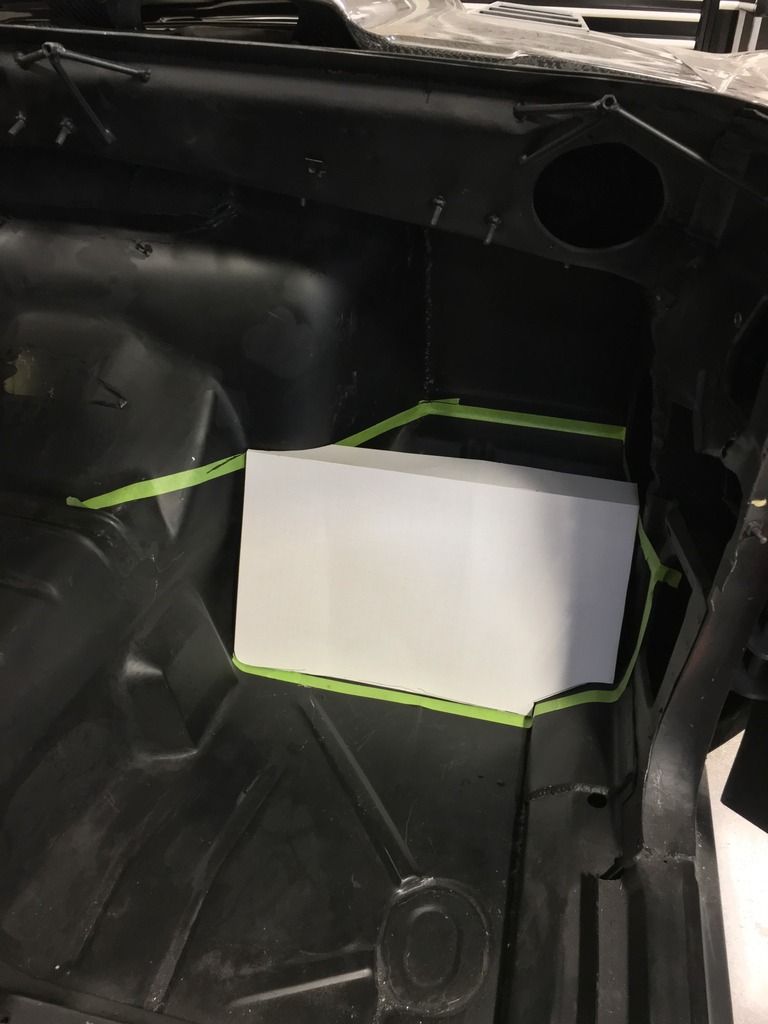

Start with cardboard to see how it looks and check clearance to the HVAC.

With it fit pretty good I went ahead and cut it in metal and rechecked the room behind it for the modules

As I was pretty happy with the additional room I went ahead and cut a hole cover and bead rolled it. Now I need to build a frame to mount it to, mount the modules, and build a top enclosure to the firewall.