|

|

03-27-2024, 03:07 PM

|

|

Junior Member

|

|

Join Date: Feb 2015

Posts: 17

Thanks: 2

Thanked 14 Times in 6 Posts

|

|

1949 Cadillac Series 61 Build

1949 Cadillac Series 61 Build

Well I'm back. The car sickness has me again after a few years away. I found a 1949 Cadillac Series 61 for sale and picked it up for a reasonable price. Some people call this a Sedanette, but really that's for the previous body style. Either-way, it's the 2 door. It's still in shipping and should be here tomorrow but I thought I'd ask the questions now so I can research more on this rainy afternoon.

I've built a few cars in my garage before over the years, done frame off restorations, built engines, wiring, and a lot of welding panels for rust repair or improved gap fitment. I have this idea now that I think I'd like to build my own suspension for this car whether that be a front clip type of set up or just fully commit to the full frame. If I go full frame I know I need a frame table / jig. I've been trying to read any books I can get my hands on for this and have used the search function to find a couple main ones used. Honestly I know I can build jigs and level them, I'm mostly concerned with the math behind the forces and angles for set up and ride quality.

Since I've been out of the hot rod arena for a few years, I'm checking to see if my thinking is still the most current "best practice". This isn't going to be max performance or Pro shop built high dollar. I can only hope my skills make it look near that way at the end.

Car goals: 75% street and stop and go (I'm outside of Washington D.C. right now), 25% back roads and some autocross / track days if I can drive the car there. I'm not trailering the car to an event. Most companies don't make sheet metal, never mind parts for a 1949 Cadillac, which necessitates the fabrication approach I'm pursuing. The old C10, mono piston, front disk swap to 1949 Cadillac is not what I want to do here.

What parts should I look at / does my selection make sense?

1. Spindles - I'm looking at using used C5,C6,C7 uprights / spindles for this (I like this because if I decide to do AWD later I have something there to use) Brakes also bolt right on and are decent price.

2. Brakes - C6 or replacement

3. Control Arms - (This is the part I'm trying to math out along with control arm mounting, size, etc). I may be able to use stock C5 / C6 but I'm waiting to get the car to get frame measurements to determine if I need to make customs ones due to overall track width. Ball joints along with car weight / C.G. / ride height become my next thought - it's not a corvette.

4. Rims / Tires - I'd like to run a wider tire and plan on using rims that make the car look like it's still on a 15" rim to make it look period correct and use a hubcap. I'm open to rim and tire sizing opinions but my main concern is tire availability and cost. It the tires are so expensive it's a pain to maintain well that's just not for me. Common wider sizes from a Camaro / challenger /older Corvette is where I've been looking so far.

5. Rear axle / Rear Suspension - I may try to do an independent rear by using something out of a more modern Camaro. It may bolt up, or I may have to build control arms and may as well use Corvette uprights to match at that point unless a better upright is recommend. If independent rear is off the table, it's a 9" floating that I'll weld in a jig. Are we still using 3 links or has someone found something better for this type of application?

6. Engine - I'm going back and forth on this. I'm going to see what shape the 331 Cadillac is in first as 1. it's tied to the VIN, 2. Its the original engine and kind of cool / different at this point for a build. I know it makes no power, but I'm thinking a mild rebuild (pistons, rods, hone, balance) 390 Cadillac Heads and a set of VS mirrored turbos may push that thing to my power goal of ~450 RWHP / TQ. If it's trash, I have a 6.0 that was rebuilt with forged internals, Bullet cam, and texas speed intake with A/W intercooler and twin turbos. I have it kicking around.. but it's way more than I want this car to be... but it's an engine.

7. Transmission - T56 magnum or 8HP90 (or similar) I'd like to do AWD, but I cannot find a way to couple a T56 Magnum or 8HP90 to an AWD transfer case (Maybe SCS gearbox - "Straight Through" and disconnect the front differential electrically, but I'm waiting on the car and for other things to be answered before I pursue that research more).

8. Suspension - Coil-over or if I can get a similar setup to the magnetic adjustable ride that Chevy uses, that would be nice and allow for more general use than all out track slayer and slammed ride.

Is there a program that people use other than building this all piece by piece in fusion 360 and seeing how it all fits and works together prior to raising the cutoff wheel and grinder? It's still cold enough that I wouldn't mind building this plan virtually first to test out a few concepts for the best solution. Please find the holes in my suspension idea. The engine and transmission stuff is mostly there for power, packaging and weight reference info for now.

Pics tomorrow / Friday once it's here and I start tearing into this. May start a youtube channel too idk.

- Alex

|

|

The Following 5 Users Say Thank You to QUA-HOON! For This Useful Post:

|

|

03-27-2024, 03:39 PM

|

|

Senior Member

|

|

Join Date: Nov 2012

Location: Vancouver,B.C. Canada

Posts: 203

Thanks: 1

Thanked 34 Times in 22 Posts

|

|

.

.

Oh ya! Great choice for a hotrod I'm looking forward to your build...

Dave

|

03-27-2024, 09:29 PM

|

|

Lateral-g Supporting Member

|

|

Join Date: Nov 2008

Location: Dunwoody, GA

Posts: 6,471

Thanks: 1,007

Thanked 704 Times in 549 Posts

|

|

This definitely will be interesting to see. Best of luck with it, Alex.

__________________

Trey

Current rides: 2000 BMW 540i/6 and 86 C10.

Former ride: 1979 Trans Am WS6: LT1/T56, Kore 3 C5/6 brakes, BMW 18in rims

|

|

The Following User Says Thank You to WSSix For This Useful Post:

|

|

03-31-2024, 05:42 PM

|

|

Lateral-g Supporting Member

|

|

Join Date: Oct 2007

Location: Texas

Posts: 106

Thanks: 1,805

Thanked 29 Times in 25 Posts

|

|

That is a sweet looking car!

|

04-01-2024, 08:37 AM

|

|

Member

|

|

Join Date: Oct 2011

Location: Roseburg, OR

Posts: 86

Thanks: 0

Thanked 32 Times in 17 Posts

|

|

C5 suspension components look to me, to be robust enough.

The thing to watch with C5 spindles is the location of the steering arm. There ARE kits to fix this, but the stock location of the outer tie-rod end sphere requires a very high placement of the steering rack to make the bump-steer work. This either puts your engine up higher, or requires you to move it backward.

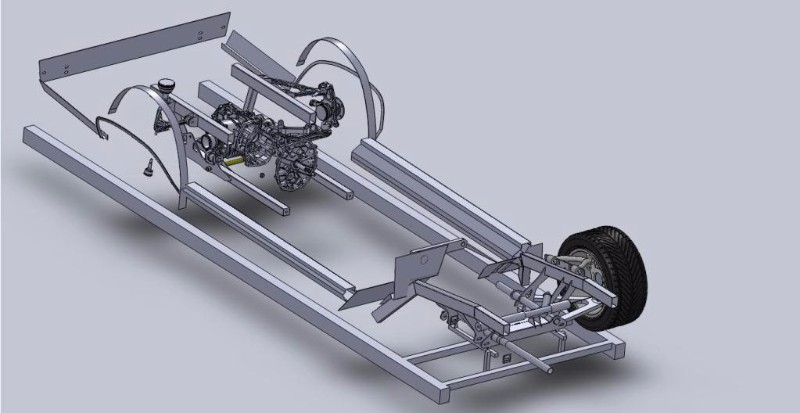

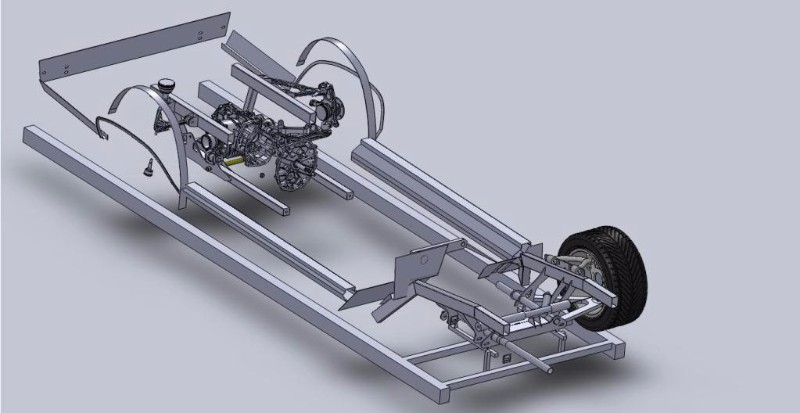

I used Solidworks to design the suspension and frame for my Nova project. It helped a ton!

|

|

The Following 4 Users Say Thank You to nickcornilsen For This Useful Post:

|

|

04-01-2024, 09:54 AM

|

|

Senior Member

|

|

Join Date: Nov 2006

Location: Mountain Springs, Texas

Posts: 1,892

Thanks: 1,101

Thanked 484 Times in 267 Posts

|

|

Check out these C5/6 adapters from Dobbertin Performance. I used these to put full C5 suspension, steering, brakes and drivetrain under my 56 Chevy Cameo. A lot of the hard work is done for you. Website also has some good info.

https://www.dobbertinperformance.com/

Don

|

|

The Following User Says Thank You to dhutton For This Useful Post:

|

|

04-03-2024, 10:16 AM

|

|

Junior Member

|

|

Join Date: Feb 2015

Posts: 17

Thanks: 2

Thanked 14 Times in 6 Posts

|

|

Quote:

Originally Posted by nickcornilsen

C5 suspension components look to me, to be robust enough.

The thing to watch with C5 spindles is the location of the steering arm. There ARE kits to fix this, but the stock location of the outer tie-rod end sphere requires a very high placement of the steering rack to make the bump-steer work. This either puts your engine up higher, or requires you to move it backward.

I used Solidworks to design the suspension and frame for my Nova project. It helped a ton!

|

Thanks for the reply and the info on the C5 spindles. I was thinking the same thing about the R&P placement.

Are you super familiar with Solidworks? I only ask because a lot of people point to Fusion 360 as a good tool for a hobbyist. So long as I can use Solidworks as a new guy I'd probably use that as my friend has it too.

- Alex

|

|

The Following User Says Thank You to QUA-HOON! For This Useful Post:

|

|

04-03-2024, 10:17 AM

|

|

Junior Member

|

|

Join Date: Feb 2015

Posts: 17

Thanks: 2

Thanked 14 Times in 6 Posts

|

|

Quote:

Originally Posted by dhutton

Check out these C5/6 adapters from Dobbertin Performance. I used these to put full C5 suspension, steering, brakes and drivetrain under my 56 Chevy Cameo. A lot of the hard work is done for you. Website also has some good info.

https://www.dobbertinperformance.com/

Don |

Thanks for these! I've been looking at these too. I have to wait until it stops raining out.. but I think a lot of people are going to be in the same camp as me after seeing how small and thin the 1949 frame is. My 57 Cadillac looks like a tank compared to this thing.

- Alex

|

|

The Following User Says Thank You to QUA-HOON! For This Useful Post:

|

|

04-03-2024, 01:34 PM

|

|

Member

|

|

Join Date: Oct 2011

Location: Roseburg, OR

Posts: 86

Thanks: 0

Thanked 32 Times in 17 Posts

|

|

Quote:

Originally Posted by QUA-HOON!

Thanks for the reply and the info on the C5 spindles. I was thinking the same thing about the R&P placement.

Are you super familiar with Solidworks? I only ask because a lot of people point to Fusion 360 as a good tool for a hobbyist. So long as I can use Solidworks as a new guy I'd probably use that as my friend has it too.

- Alex

|

I've been using solidworks for at least 20 years now... but I taught it to myself using you tube and how-to guides. I find it pretty straight forward.

|

|

The Following User Says Thank You to nickcornilsen For This Useful Post:

|

|

04-03-2024, 05:41 PM

|

|

Junior Member

|

|

Join Date: Feb 2015

Posts: 17

Thanks: 2

Thanked 14 Times in 6 Posts

|

|

Quote:

Originally Posted by nickcornilsen

I've been using solidworks for at least 20 years now... but I taught it to myself using you tube and how-to guides. I find it pretty straight forward.

|

I'll give it a shot then! I'll try to figure out how to build a frame in it this weekend to start this building process.

|

|

The Following User Says Thank You to QUA-HOON! For This Useful Post:

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 02:52 PM.

|