We finally got a break in the weather up here in Boston this weekend and I took full advantage and got a lot done in the garage. I'd been working hard to get the engine and transmission ready to remove from the car and I was finally able to get them out this weekend. I'm lucky to have my Dad living nearby and he came over for the day to lend a hand.

I had never pulled an engine, so this was a new process for me. I spent a lot of time researching how to position the crane, how to attach the crane to the engine and so on. I had bought a load leveler but wasn't able to get it hooked up to the thread holes in the back of the engine. Here is the setup I ended up using:

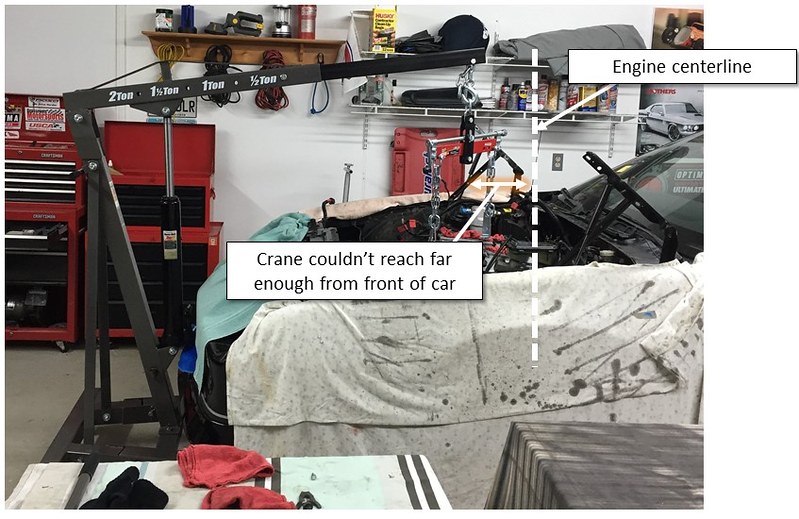

My crane was a bit short to reach the center of the engine from the front. Looking back, I could have maybe made this work, but I ended up going from the side instead.

Final setup:

Before we pulled the engine, I wanted to pull the transmission from under the car. I attached my scissor lift and was able to get to 7 of the 8 bolts holding the transmission to the bellhousing. For the 8th one at the top, I loosened the engine mounts and lowered my scissor lift, essentially angling the transmission down so I could get at it. Once that was done, I disconnected the clutch fork and out she came!

Next we started on the engine. I had left quite a few pieces on the engine thinking I could remove it with them still attached, like the headers and the bellhousing. Our biggest issue was that we couldn't get our hook on the crane perfectly centered, so the driver's side of the engine was rising much faster than the passenger's side. This caused the passenger's side header to keep getting caught on the frame:

So, off it must come. I was TERRIFIED to remove the headers in the car because of the horror stories I've heard about breaking of bolts in the head and the difficulty of getting to some of the bolt heads. Luckily though all of them moved freely. I had to get creative with a couple of them and ran out to grab some stubby wrenches but eventually we got it out.

I got lucky here:

After getting passed that snag, we just took our time and slowly inched the engine up and forward until it was clear of anything holding it back. I was nervous as it was hanging 5ft in the air over my fender but it all worked out OK. Here are some more pictures:

Slowly creeping upwards:

I was terrified at this moment:

My Dad and I:

Safely out of the car:

We finised the day with the engine on it's stand and the transmission on a table ready to be gone through. I was super happy to get this done so smoothly, I now feel like a real car guy since I can say I've pulled an engine! Now the fun can start!