Spent a lot of time in the garage this weekend but unfortunately not a lot of the work was photo-worthy. I had a table full of parts that needed to be scraped, scuffed, cleaned and painted so I spent the majority of the time doing that.

Just a couple crappy pics of the freshly painted pieces:

Next I tackled my cracked AC box. I ended up using some Permatex Plastic Welder I found at my local Advance Auto. It was only about $6 for the tube and seems to be working OK so far. Since it's still cold here, I'm going to give it a while to set before I sand and paint it.

I did not get a picture of it, but I first drilled the ends of the cracks and then used my Dremel to create a little V-channel out of each crack to help it hold the plastic welder.

Plastic welder applied:

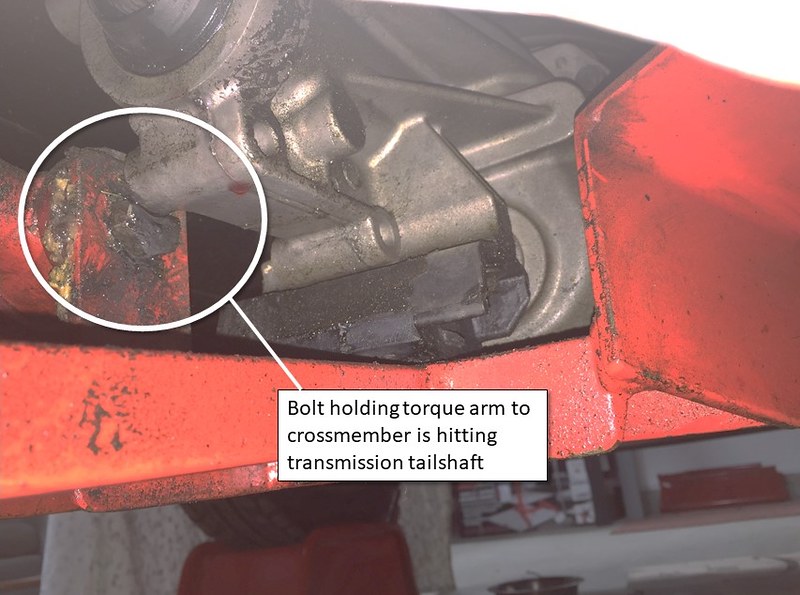

The next job was addressing the interference problem between my transmission tailshaft and the bolt that holds my torque arm to the crossmember. This is what it looked like before I took it all apart:

I trimmed a small piece from my tailshaft which I'm hoping will cure the issue. I took as little material as possible and then blended in any sharp edges to minimize the chances of creating a stress riser:

I ended my weekend by rotating my engine on its stand and spilling coolant and oil everywhere. Awesome!

There was way more in there than I expected! I thought it was a good time to call it quits for the day after that...