So before I got around to safety wiring the rotors I had to build them up. It is a simple exercise but it took a bit of time to do. Part of this is me being anal about putting them together.

Why worry about assembling brake parts right.

I'll run through this quick. It also gives me a chance to show off my Wilwood floating hats.

Here one is.

It's AL like most of the front hats but you'll notice the T slots in it instead of just threaded holes.

Into these you inset these little T nuts.

Man that is a crappy picture. I can't wait to hear GWs comment on that one.

This allows the rotor to "float" on the hat. This really separates the hat and the rotor into two separate pieces. Having two separate sections of the rotor and hat helps to keep heat generated in the rotor off of the hat. By keeping the hat cool you are less likely to have any flex, giving you more feel and braking predictability under extreme braking conditions. A floating rotor also allows for much more contact surface between the rotor and brake pads since the rotor itself follows the path of the pads correcting any imperfection either may have as it floats.

Now with anything that requires a definitive torque value I make sure the threads are clean and free of burrs. In most cases that means a quick run of a tap through the threads.

In this case the stainless bolts are nice and hard compared to the T nuts so I just dry fitted them. If any of the bolts had bound as I was assembling the rotors I would have got a tap out for that one.

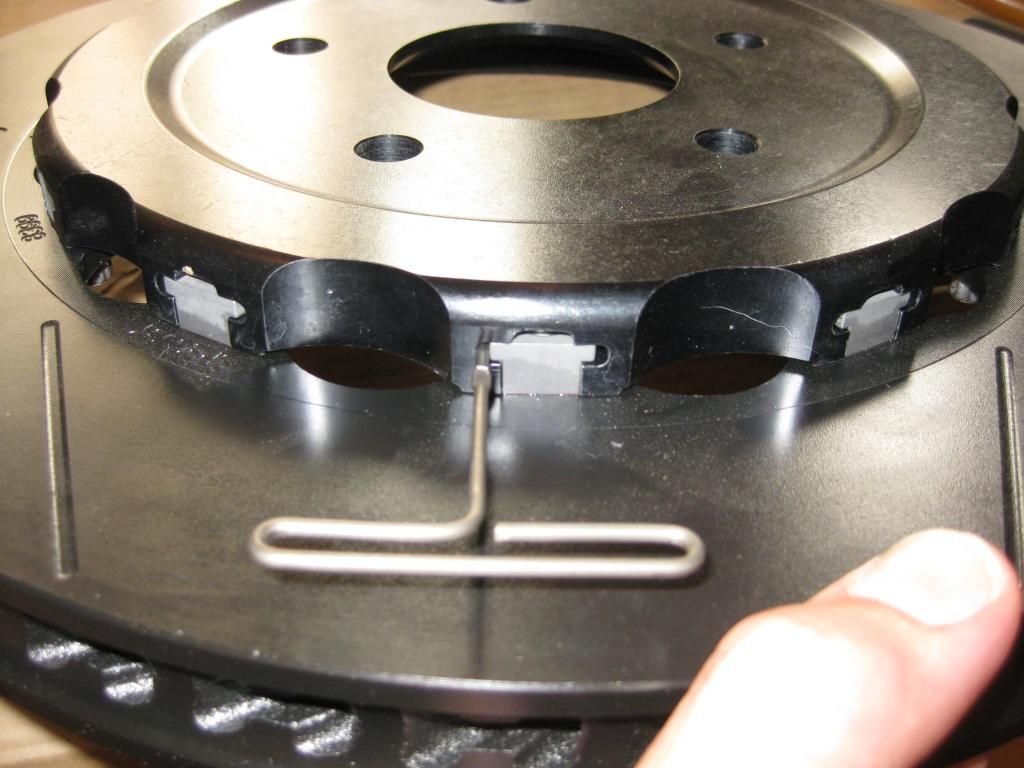

With these T nuts you use a small T wire to ensure the nuts don't rotate as you torque the bolts.

I didn't have any issues with this set. Once the rotors are completely assembled to hand tight it's time to loctite and torque them.

I use two sockets of the same size to make the next step easy. Once I torque a bolt I leave the socket on it and then go to the bolt directly across to torque in a criss cross pattern. the first socket serves as a marker to remind me where I just was.

Once you put a bit of loctite RED on all the bolts bolt and torque them to 125 in lbs (in this case) it's time to get out the safety wire pliers.