So my lack of talent (frustration) with steel has basically left me scared to attempt aluminum

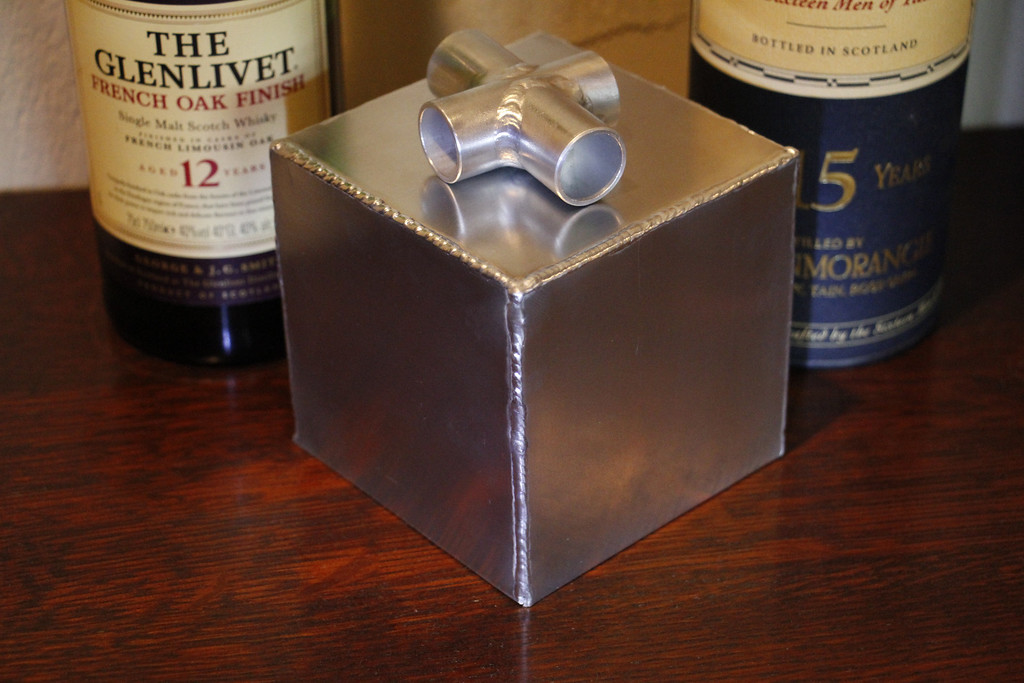

Wednesday I attempted aluminum for the first time. The box and tube are 16g 6061. I don't know why but it seems much easier for me, maybe because I can see the work area better?

While the beads are far from perfect it feels like a victory.......now which scotch do I reward myself with?