continued from above

Seat mounting to the chassis is also critical to safety. The positioning of the seat determines your sight lines, comfort, and safety. We can handle all of that, but what about the seat itself?

If you have the grip levels of massive Hoosiers (left), you better have appropriate seats to deal with that (right)

If you have the grip levels of massive Hoosiers (left), you better have appropriate seats to deal with that (right)

I wouldn't think about running a car with big Hoosiers (1.3 to 1.5 g) on a stock seat. We needed to pick a

better seat for this Camaro, as the capabilities and grip levels would likely be higher than any modern super car and even most race cars. 345mm Hoosiers make a boat load of grip, and I know from running these in the past, you better be strapped into a GOOD seat if you want to be in complete control. High leg bolsters, shoulder support, and a halo around your helmet.

This LaJoie seat was one of 3 seats provided by the customer when he brought the car to us. It is an aluminum, 2-piece seat marketed largely to the circle track crowd. We all felt that while the better versions of these look beautiful, works of art, they fell short. As an aside, it just didn't fit the theme the customer requested, a serious track car using

modern sports racing components, drivetrain, tires and aero. There's very little circle track influence here. Also, this car had to have a second seat in it that was somewhat similar to the driver's seat - and buying another LaJoie was not in the cards.

The build also came with a pair of brand new Sparco EVO II and EVO III seats. The EVO III is huge, and was too big for the owner. The EVO II fit him well, and we sell and install a lot of these (and just put one in my

NASA TTD prepped BMW E46), but this project needed something more serious. The lack of lateral shoulder and head support was a deal breaker on this level of build.

Yes, we sell all manner of racing seats, and I keep about a dozen in my showroom for "test sitting". Nothing beats sitting in a seat to see how you fit. One of the most respected names in racing seats is Racetech, but we had never bought a seat from them before. They do some of the best tests and their "crash test" share videos like

this side impact test rig video. That seat back movement in a side impact made us look at their 119 series of seats.

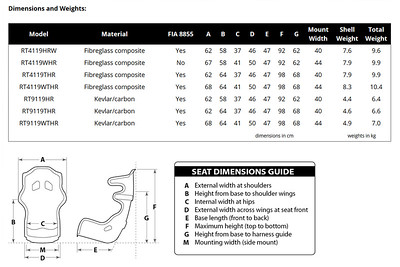

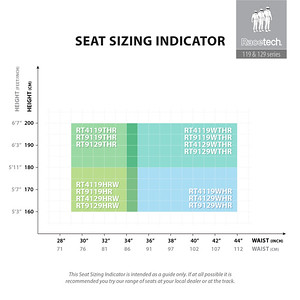

I'm trying not to be sales-y here, and if you look on our website you won't even see Racetech listed, but the features are hard to ignore. They make an unprecedented FOUR sizes of the 119 seat - combining normal and tall heights, plus normal and wider widths.

For the owner of this car we had him test sit in some seats, send in several body measurements as dictated by Racetech, and then looked at

the sizing chart and determined he needed the normal width in the tall height - the 4119THR.

These 119 series seats are a bit pricey, and the carbon fiber versions (9119) are extremely expensive, so we went with the 4119 composite seat range for the driver's side seat. The passenger will get one of the Sparco EVO seats, but there won't likely be too many laps with a right seat filled at 10/10ths pace.

WHAT'S NEXT?

This 2-part write-up took us from January through April. A lot of time was spent with the chassis or body at the painters, and any of you that have built a project like this would understand how long paint work takes - even partial paint or priming work.

Next time I will show the body going back into the frame, then the aluminum flat bottom undertray panels and floors being built, the exhaust routing through the tunnel, the dash and cowl work, then firewall and sheet metal fab up front. Lots to cover, hopefully I'll have time this weekend to write another segment to catch us up closer to real time.

Cheers,