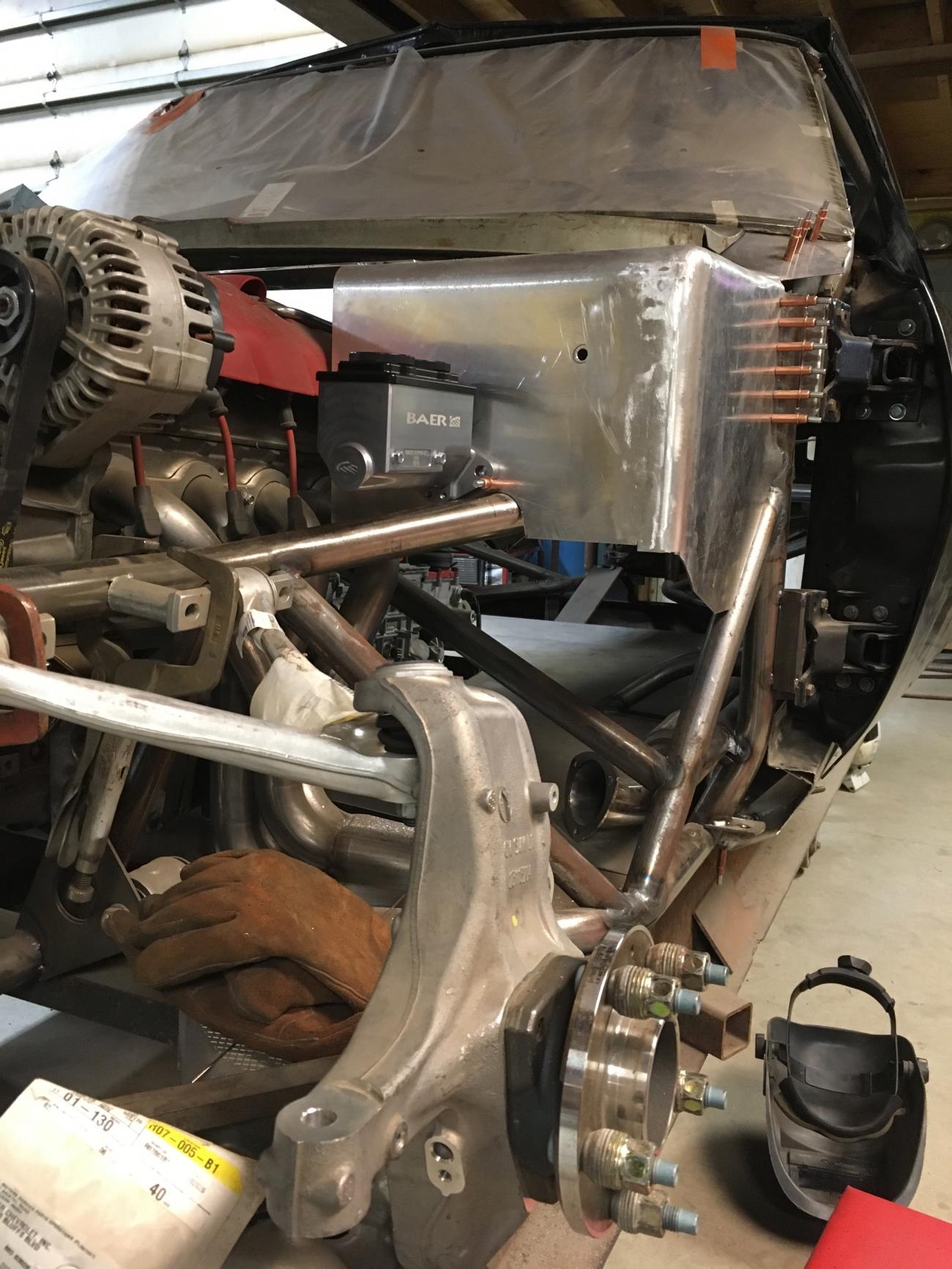

Just getting around to posting information on my project after spending a couple of years reading about all of the other projects on here. This one started as a bundle of docul (chromoly) tubing and a stack of boxes of repop sheetmetal.

My goal is to make it as light as possible and keep the COG as low as possible. It is getting an ls7, a tko600, C4 corvette rear gear and c7 corvette suspension on the underside. The body is all of the AMD aluminum camaro parts sans the fenders, fenders are anvil carbon, doors are from ultra-carbon, and the rest is steel for now.

Quick shot after tonights work. All of the interior sheet metal is 16ga aluminum.