I am converting over to power steering with Unisteer's Gen II kit and the ATS/Lee 670 box. So I needed a solution for my pulley setup.

Here's my current setup, short water pump driving only the alternator

(BTW the Ron Davis Radiator you see is awesome)

What I needed was a alternator bracket that met several criteria:

1. Run everything from 1 belt

2. Keep the alternator on the driver side

3. NOT a header mount bracket, which I despise

4. Give enough room to allow clearance for the Gen II pump

5. Allow enough "bite" on the PS pump pulley

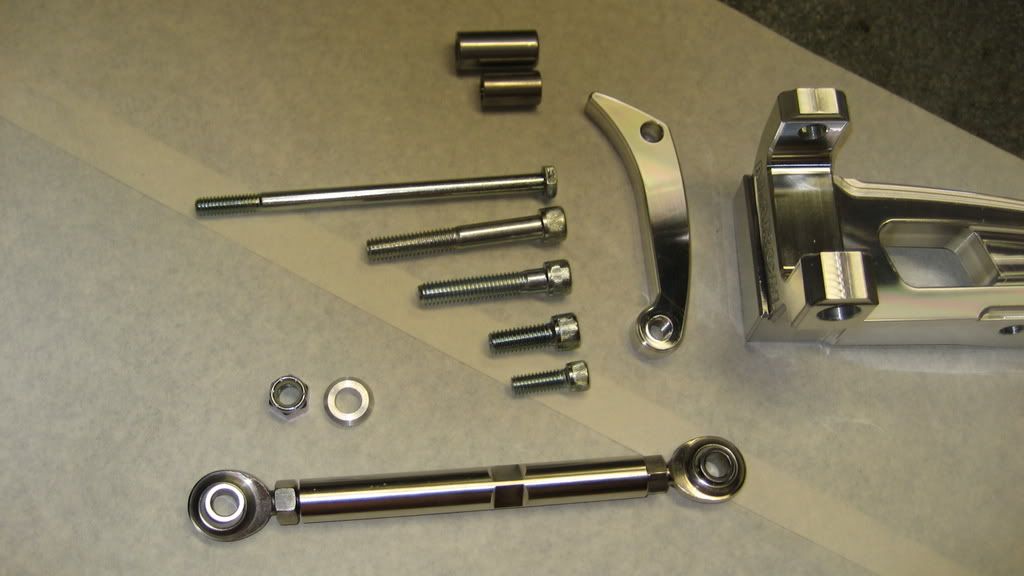

After much research, I was left with very few options. As I mentioned in my first post, I don't really go for the "bling parts." But I have to admit that I am pretty darn impressed with this alternator bracket I bought. It's a March product that I bought from Summit (MCH-20131). $160 dollars for a bracket isn't exactly my idea of a deal, but I really got what I paid for:

Note the longest bolt in the picture above, used to bolt the alternator up to the bracket. This is the 1/4" bolt that was included in the box, But it is is completely wrong...It should be 3/8" with an allen wrench head (Hex cap) just like every other bolt you see. I don't know how it got in there, but I had to run down to the hardware store to get the correct one.

Also, the shortest bolt you see wasn't correct for my application either! This is the bolt that is supposed to thread into the top hole of the alternator, holding the piece that the turnbuckle mounts to. The thread on the bolt is coarse, while the thread of the alternator is fine (or vice versa, I can't recall). I just simply reused the bolt I already had. These are the type of hangups that I have learned to accept very early in this project.

Here it is on the car:

As you can see, it makes use of the 3/8" drilled accesory holes in the Pro-Topline heads, and provides awesome adjustability with the turnbuckle. It took several hours to install this bracket because I wanted to be sure that the bolts wouldn't bottom out when threading into the aluminum head. I actually bought a bolt that was a smidge shorter and touched it with a grinder, just to be sure. You can see the replacements (in black) HCS that I used to properly install the bracket and alternator. Mismatched bolts build character!

Whether it meets criteria 4 & 5 remains to be seen...I sure hope so.