|

|

12-20-2005, 11:15 AM

|

|

Senior Member

|

|

Join Date: Jul 2005

Location: Carlsbad, CA

Posts: 375

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

There are two issues with regard to drag race style four link and ladder bar systems that make them highly undesireable for street applications. As Marcus pointed out, a suitable lateral locating device such as a long Panhard bar is a must for the street, the drag race kits typically come with a "diagonal" link, useless for controlling side to side motion of the car reliably, and frankly, dangerous as a result. A good friend of mine recently bought a four link 57 Chevy with a diagonal bar, he got "concerned" when he could hear rubbing of the rear tires, and could get a whif of rubber. The rubber turned out to be two things, tires, and far worse, rubbing on the fuel line. Swapping a simple Panhard rod completely transformed the car, and made it remotely livable on the street.

The other issue is that the drag race setups use spherical rod ends for the pivot points. While it is obvious that the ladder bar setup has serious bind issues in roll situations (i.e. any cornering), the same condition exists for the four link setups using rod ends also. The only reason that either of them roll at all is because something in the system is bending, stretching, etc. BOTH are overconstrained in roll, period. I think the reason that folks think the four link systems don't bind is that there is actually more stuff to bend, so the bind is less obvious. Further, using some form of compliant bushing in a four link (rubber, poly, etc) will free things up a bit and allow the setup to roll more, until of course the bushings are fully compressed.

A three link has the advantage of being completely free in roll-bind situations, by design. Each of the links only has one job to do, the redundancy of the two upper links is eliminated by removing one of them. Three link setups also require a Panhard bar or other lateral locating device, such as a Watt's linkage. You will be seeing a good number of three link applications on the market very soon.

Mark

Edit: Spelling

|

12-21-2005, 09:32 AM

|

|

Member

|

|

Join Date: Dec 2004

Location: Mid-Michigan

Posts: 76

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

With all of that said I would recommend sticking with your leaf springs. If this is a street/sometimes(maybe) track car there is nothing out there that will outperform the leafs on the street AND give a decent showing on the track with some tuning.

I was doing the same dance you are when I was bubbling up my Astro van project. I talked to a LOT of people before I decided to stay with leaf springs. The ONLY thing leaf springs have going against them is; they are not high tech. Mundane and Simple work very well though and there is a lot to be said for simple. Like "cheap", "no maintanence", "easy to tune" and "not a major tearup to install". Unless of course there is some narrowing involved...

Mark

__________________

"Bad Ast" Astro Van Pro-Touring Project.... Heat, beat, file to fit, paint to match...

|

12-21-2005, 09:41 AM

|

|

Member

|

|

Join Date: Dec 2005

Posts: 22

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

Quote:

|

Originally Posted by astroracer

With all of that said I would recommend sticking with your leaf springs. If this is a street/sometimes(maybe) track car there is nothing out there that will outperform the leafs on the street AND give a decent showing on the track with some tuning.

I was doing the same dance you are when I was bubbling up my Astro van project. I talked to a LOT of people before I decided to stay with leaf springs. The ONLY thing leaf springs have going against them is; they are not high tech. Mundane and Simple work very well though and there is a lot to be said for simple. Like "cheap", "no maintanence", "easy to tune" and "not a major tearup to install". Unless of course there is some narrowing involved...

Mark

|

looks like im going with mopar SS leafs(much thicker and stiffer) which I heard should prevent axle wrap(since i dont want to do traction bars) but i heard they are stiff, unless there is anything i can do to prevent wheel hop and axle wrap with stock rate leafs

Im gonna use the mopar relocation kit(which is kinda old school and ghetto, but works and moves springs in 3-4") and just get some koni shocks i think

For hte front im gonna go with a 1.12" torsion bar, koni shocks, full rebuild kit and upper control arm.

Subframe connectors and a 8 point roll cage will finish it out.

18x10" mustang bullitt wheels(since they fit) on 295/35/18 drag radials

18x9" front with 255/40/18 tires

We'll see how it turns out, i want a low, mean, pro touring look and a car that at least handles decently(its a long, boat so i can only get so much)

|

12-21-2005, 09:47 AM

|

|

Member

|

|

Join Date: Dec 2005

Posts: 22

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

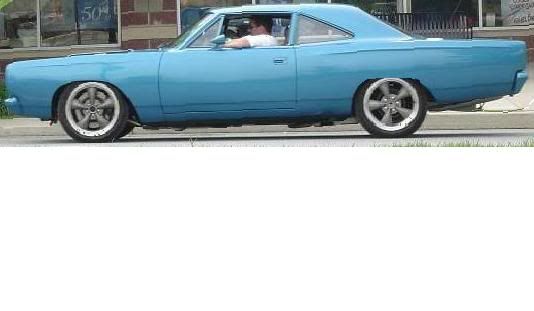

this is the look its going for(same wheels, different color)

Car is gonna be either black, or silver with those wheels but in black/polished lip

|

12-21-2005, 10:22 AM

|

|

Junior Member

|

|

Join Date: Dec 2005

Location: Michigan

Posts: 6

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

If you want low with Mopar SS springs you will need to have them dearched. In my mind a better way to go would be to spec a custom spring from Eaton Detroit (Pure Vision used them on Dust Ya' and Hammer) or your favorite spring supplier. They can build a spring that gets the back end sitting at the ride height you want and have the right spring rate for your setup.

All the Mopar SS springs are based on the shorter A-body units, so you will have to verify that you can use a stock B-body length spring with the relocation kit (I don't know for sure but I think you can) or tell your custom spring supplier that you are using that relocation kit and may need the A-body length spring.

|

12-21-2005, 10:29 AM

|

|

Junior Member

|

|

Join Date: Dec 2005

Location: Michigan

Posts: 6

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

I found this in a write up about Pure Visions "Hammer" 1970 Roadrunner:

"SUSPENSION, STEERING, AND CHASSIS WILL INSTALL CONFIDENCE. Modern K-frame from Reilly Motor Sports uses coil over shocks, tubular control arms, and Flaming River rack and pinion sterring. Red Zone Race Fabrication will be mounting a custom pair of leaf springs from Eaton Detroit Springs in the car using a Mopar Performance spring relocate kit, as well as intalling custom made sub-frame connectors."

I'd e-mail Steve Strope at Pure Vision and ask him some details about his springs. I've e-mailed him before and he seems like a good guy.

|

12-21-2005, 11:03 AM

|

|

Senior Member

|

|

Join Date: Jul 2005

Location: Carlsbad, CA

Posts: 375

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

Hey! That blue Road Runner is my internet friend Pete's car. Nice guy, and a great car.

I would move with caution on any front end replacement kit on the market today, there seems to be some pretty significant issues with them from all that I have talked to that have direct experience.

Quote:

|

its a long, boat so i can only get so much

|

It seems like we are not going to be ready for your project timeline for the front stuff in particular, but I have full confidence that our suspension systems will make that comment obsolete! Our shop car is expected to be complete and will be shown at the Mopar Spring Fling this coming year, I think it will change folk's impressions of what can be done to Mopars in terms of honestly good suspension setups.

Whatever you decide, have fun with your project, enjoy every second of the build and best of luck with it.

Mark

|

12-22-2005, 07:34 AM

|

|

Senior Member

|

|

Join Date: May 2005

Posts: 292

Thanks: 12

Thanked 25 Times in 14 Posts

|

|

Quote:

|

Originally Posted by Mean 69

The other issue is that the drag race setups use spherical rod ends for the pivot points. While it is obvious that the ladder bar setup has serious bind issues in roll situations (i.e. any cornering), the same condition exists for the four link setups using rod ends also. The only reason that either of them roll at all is because something in the system is bending, stretching, etc. BOTH are overconstrained in roll, period. I think the reason that folks think the four link systems don't bind is that there is actually more stuff to bend, so the bind is less obvious. Further, using some form of compliant bushing in a four link (rubber, poly, etc) will free things up a bit and allow the setup to roll more, until of course the bushings are fully compressed.

A three link has the advantage of being completely free in roll-bind situations, by design. Each of the links only has one job to do, the redundancy of the two upper links is eliminated by removing one of them. Three link setups also require a Panhard bar or other lateral locating device, such as a Watt's linkage. You will be seeing a good number of three link applications on the market very soon.

|

While it is true that most "drag racing style" four links (which are really five links when you count the panhard or track bar) are overconstrained in roll, that is not true of all four trailing link setups. Four trailing links, with one pair angled and no panhard, is kinematically free (Art Morrison uses this setup on many of their chassis). Also, although I've not yet fully worked out the kinematics in my head, I think the DSE four link is on the right track by introducing a rotational degree of freedom on roughly the roll axis. I'd bet that the DSE setup is very free in roll.

In other respects - roll center, instant center - four parallel trailing links are no different than three from a design perspective, so if the issues with binding in roll are sufficiently solved, it comes down to the specifics of design and packaging. It really comes down to the design goals for the system, and the competence of the designer in achieving those goals, which is where the most important differences between systems are really manifested.

|

12-22-2005, 08:22 AM

|

|

Senior Member

|

|

Join Date: Jul 2005

Location: Carlsbad, CA

Posts: 375

Thanks: 0

Thanked 0 Times in 0 Posts

|

|

Quote:

|

Also, although I've not yet fully worked out the kinematics in my head, I think the DSE four link is on the right track by introducing a rotational degree of freedom on roughly the roll axis. I'd bet that the DSE setup is very free in roll.

|

Not sure what you are referring to? The bushing design? If so, this is not the solution to the constraint problem with a four link (parallel/semi-parallel). The issue is that one upper link needs to get a bit longer, or the other to get a bit shorter in roll in order to create a bind free system. Their bushing design is rotationally "free," at least statically (not sure how it will work when it is loaded in the actually suspension with a thrust load applied to the swivel thing they patented?), but this isn't where the binding issue comes into play. Think of it this way, a rod end has the same rotational freedom as their (unloaded) bushing, though it clearly can't rotate 360 degrees: it still has enough to accomodate the amount of roll angle induced by the axle in practical terms. If you agree, and look at the system with this in mind, you'll see what I am getting at. Again, the reason their system will work in roll is due to the compliance (radial, in this case) of the bushings used.

As far as the side view kinematics and rules, you are completely correct, the four link setup has no disadvantage, nor advantage over a three link, the same rules apply. Here again, the geometry of the system in side view is VERY important in determining the behavior of the vehicle, and it gets even more interesting when you look at how it behaves dynamically, it's not enough to say that the roll center height, IC, etc are "this" by design, one needs to consider the migration aspects of the system in practice to see how the car will behave in real life.

And regarding the AME stuff, the suspension engineer on my team happens to have a few years of direct experience with that setup.

Mark

|

12-22-2005, 09:39 AM

|

|

Senior Member

|

|

Join Date: May 2005

Posts: 292

Thanks: 12

Thanked 25 Times in 14 Posts

|

|

You're right, introducing an axial rotation DOF in each link will still leave the parallel 4 link overconstrained, but it will remove one additional overconstraint in the case of poly bushings at both link ends, without the NVH and wear issues of heim joints. From that perspective, a three link has the same issues. Just how much remaining deflection is required to accomodate roll in the normal plus/minus few degrees range is the question I don't have the answer to, but if the resulting roll stiffness introduced by the deflection is a low percentage of the total roll stiffness created by springs and sway bar, it will not be a significant factor in the handling. Engineering is the art of informed compromise, and what appears to be a compromise may be well-informed or not.

I completely agree that roll center, roll axis, roll steer, and instant center, and the variance of those parameters through the suspension range, are the primary determinants of the handling characteristics of a rear suspension design. For consumers of these products, if the vendor can't answer what those parameters are for a given design, and why those parameters were chosen, it is a complete crapshoot whether the design will "improve" handling. And to make the point I was originally trying to make, you can't determine these things just by counting links.

The good news for PT guys on a budget is that plain old multi-leaf springs can do a OK job on almost all fronts, with the primary compromises being static friction (which can be reduced by careful design) and unsprung weight (which can't be fixed, unless you go fiberglass, which has its own issues).

Yeah, Katz did some pretty good work at AME. Most of those old-line chassis makers have no serious engineering in their suspension designs, but the AME stuff is pretty good. As it happens, I just picked up the Tri5 Morrison chassis for my wife's 55 BelAir a couple of days ago. It'll never see the track, but it will drive a lot better on the street!

Good luck on your new company, sounds like you guys are pretty jazzed.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:35 PM.

|