Quote:

Originally Posted by bsharpe

I spent a lot of time trying to align the subframe on my firebird. It is not easy with these cars especially on jackstands. I understood that my unibody was not perfect (the pinch welds are destroyed and she has been hit), the ford 9" and 4 link isn't perfect (I didn't measure enough when I installed it) and my subframe has some issues but I didn't expect to run into major problems and spend as much time as I did.

I used a laser level and old vinyl tiles under the jackstands to level the car. I then plumb bobbed from everything that was symmetrical on the car like holes in the frame and the pinch welds. I used a chalk line to find the center line of the car. I then squared the rear axle to the body by taking cross measurements and wheelbase measurements. I then tried to square the subframe to the rear axle. I was unsuccessful and found major issues with my subframe. I am now evaluating my options.

|

These cars have "issues" -- they're not exactly spring chickens... they've had a rough life... The point is - that you either have to get the body back to where it should be - or you have to modify things to get all of this to line up and be square and the wheelbase to be right. Whatever course that takes is a matter of skill and pocketbook... etc.

When I did my brother in laws Camaro - it had taken a hit on the driver side... so much so that I had to pie cut the area where the steering wheel goes thru the firewall... and I had to make a "spacer" to take up the area under the floor between the floor and the sub mount. We didn't have another way to fix this "alignment" issue. We made it work and the car drives perfectly. And his gaps are perfect. The key is to have accurate measurements so that you can "fix" the issue and know what you're doing. You can fix anything if you know where you need to be when you're finished.

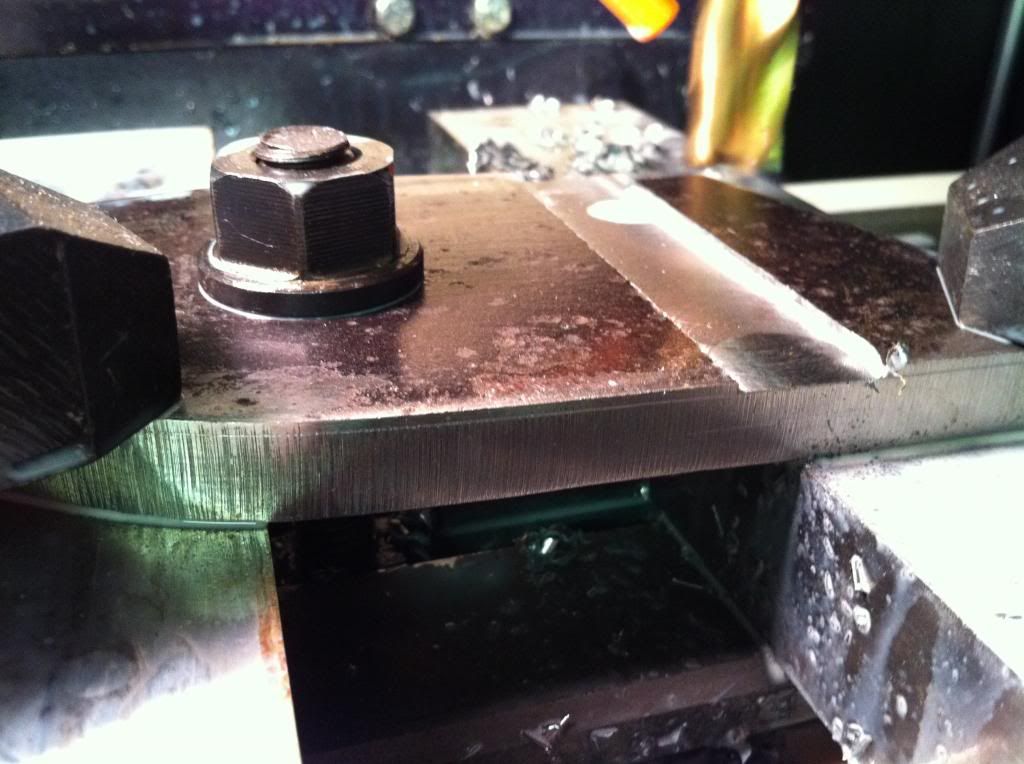

Check out this "spacer" I had to make for the driver side! I milled it to the .001 of an inch... just because... there was really no reason to get that close other than I just like using some of my tools. HAHAHAHAHAHAHAHA

It worked out just fine!