Tools For Working On LS Engines

Lately we have been working on a few different LS engines and realized there are some tools out there that can help you build these engines into the reliable, leak free engines we all love.

Now these tools aren’t absolutely necessary – you could get by without them but it’s like that old saying, you need to have the right tool for the right job. After building a few LS engines and these latest few we sat back and looked at all the different tools we use on LS engines to make working on them much easier.

On our Project ’55 Bel Air build, we were using just about all of them. This engine is a basic LM7 5.3L that we performed a cam swap on, along with changing the valve springs then resealing the entire engine. Let’s go over the specialty tools needed to perform a cam swap in an LS engine, something that lots of us do.

Crank It Up

The first specialty tool you’ll need is a crank pulley puller. Admittedly, we don’t own one of these. But your local auto parts store rents a three jaw puller for a Chrysler application that works perfectly here. This is one tool that we haven’t gotten around to purchasing on our own yet, but you can bet that’s our next purchase.

In order to get the crank pulley back on, you can’t just beat it on with a hammer. We picked up from Summit Racing years ago this crank pulley installer which is essentially a big bolt with bearings on a retaining plate to slowly press the pulley on. Using this method only takes but a few minutes before the crank pulley is back on the engine.

Cam Swap Essentials

If you’re not replacing lifters, then a cam swap is a fairly easy process. Once the timing chain is removed and the rockers are backed off, the trick is to spin the cam around a few times to push the lifters up in their cradles. Generally they stay up there long enough to slide out a cam and slide in a new one. But sometimes they don’t which means you’re pulling a head to fix it.

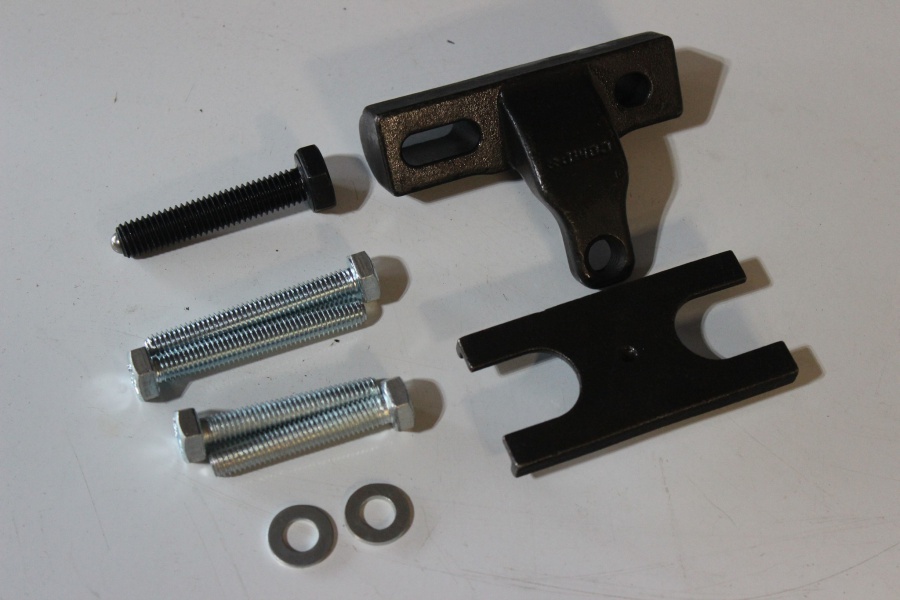

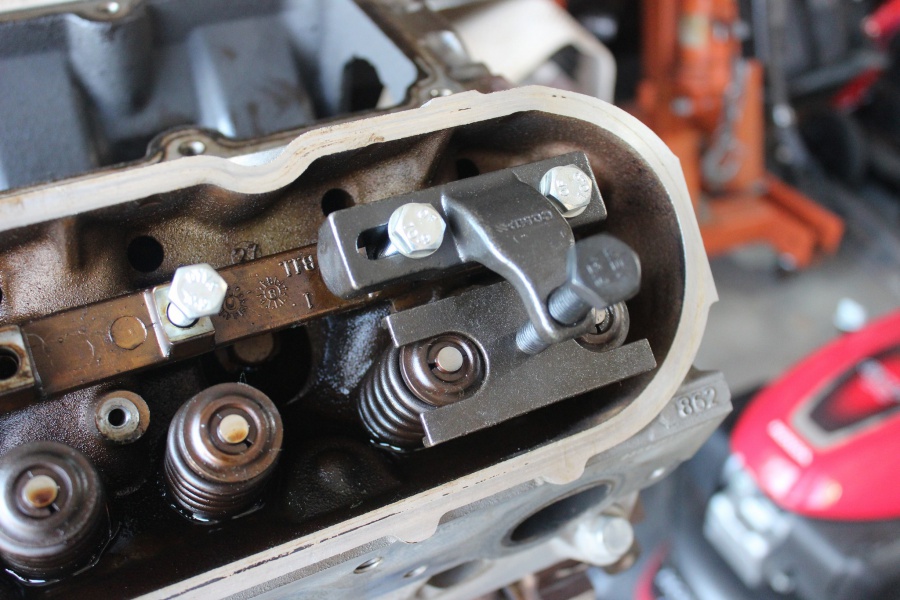

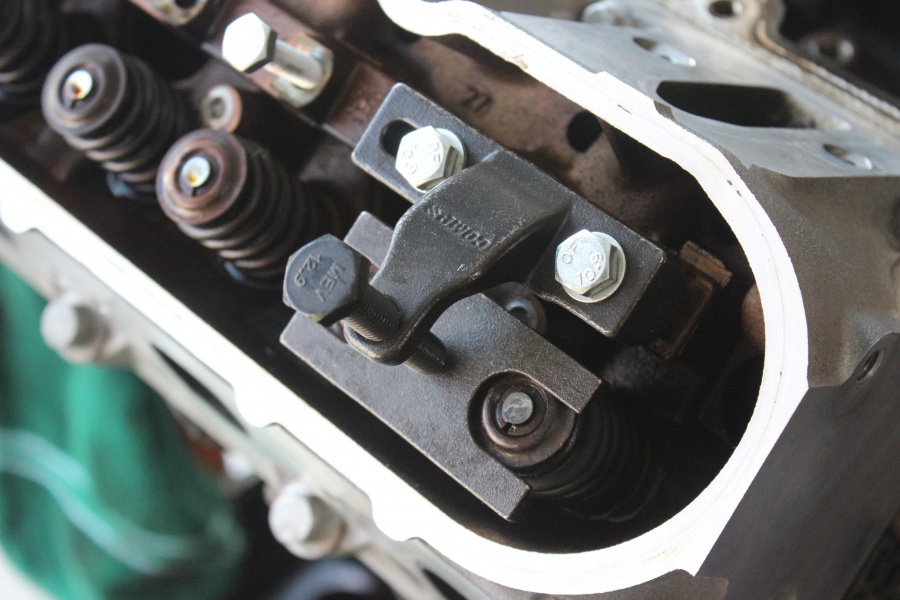

COMP Cams makes a tool, part number PW101046, well two tools really, that solves this problem and eliminates stress. They are essentially two long rods that slide into the oil galleys behind the cam retainer plate. You spin the cam around to push the lifters up then slide these rods in. They will hold the lifters in place while you take your time installing the new cam or replace cam bearings.

Is this tool necessary for swapping a camshaft? No, but it is really nice to have. Again, the right tools for the right job. While we were completing this cam swap, we wanted to replace the valve springs as well.

COMP Cams makes a really cool LS valve spring compressor tool, part number POW352001, that works insanely well. What we really liked about this one compared to others is that it’s easy to use and does two valve springs at the same time, reducing the amount of times you have to compress and decompress valve springs. It’s just a time saving tool that made our job of swapping valve seals and valve springs that much easier.

Sealing It All Up

We admit that most of us just slap the timing chain and rear main covers on and call it good. Did you know that there’s actually a better and more correct way of doing this? Imagine for a second here you have all the timing chain cover bolts threaded in, but not tight yet. There’s minimal play for that cover to move up, down, left and right – but there is play. In order for the seal around the crank to not only seal properly and last a long time, it needs to be perfectly centered on that crank snout.

Mr. Gasket makes the tool, part number VK090004, that’s needed to ensure that the timing chain cover and rear main covers are perfectly centered on the crank. They are plastic spacers that pop into the covers. A really simple tool that slides on the crank and into the cover keeping everything centered.

In order to use them you have to remove the old crank seals first. Install the tool into the cover, then install the cover. After torqueing the bolts down, you can then remove the tool and install the seal. These tools help to ensure a long lasting leak free seal.

Wrapping Up

As we mentioned, none of these tools are 100% needed – universal versions can be used to accomplish the same thing. But to do it right, save time, and ensure a long time running engine, they are needed. We look forward to getting our LM7 finished up and sitting in it’s new home soon!

For more information hop on the COMP Cams website or give them a call at (901) 795-2400. For Holley, hop on their website or give them a call at (866) 464-6553