LS Swap Radiator From Flex-A-Lite

Overheating is never a fun time. As hot rodders build bigger and more powerful engines, overheating has always been a bit of an issue. Luckily, radiator design and technology has improved just like those engines. Now you can have well over 1,000 horsepower while sitting in the hot traffic and the air conditioning cranked. It’s truly amazing to see the improvements over the last few years.

When we built our bored and stroked LS3, we knew that we would need a cooling system that would be up to par. We called Flex-A-Lite who set us up with their radiator and fan combo. After taking the car across Texas in the middle of summer with the AC cranking and not even starting to overheat, we were sold. We couldn’t believe that even in triple digit temps, hot asphalt and the AC cranked, the needle never moved.

Now that we are building Project Way-Gone, we wanted that same radiator set up as this car is LS powered as well. The difference though is we are using a junkyard, bone stock LM7 engine so the Flex-A-Lite set up should easily handle it. With one part number we were able to order the LS swap radiator and fan combo. This radiator has the inlet and outlet on the same side and a bung already welded for the steam vent. They even weld up the brackets for the fan and mount the fan!

One unique feature that the Flex-A-Lite radiator has that improves cooling over the competition is the cooling tubes. Traditionally these are wide, flat tubes with nothing inside. The Flex-A-Lite tubes are extruded with what we will call supports. For one, this would make the tubes a little bit stronger. The main benefit though is that these supports transfer heat to the outer cooling tube for better heat transfer.

You Won’t Break A Sweat With This Installation

Installation is as easy as four bolts – seriously. The radiator bolts up to the factory core support using the same four bolts the factory radiator uses. The next step was to get the cooling system plumbed then wired up. The hoses were easily enough figured out. Until we get the Restomod Air system installed, we bypassed the heater hoses. For now we just want to get the car running and moving under it’s own power.

The upper radiator hose we figured out what worked best was a Chevy Cavalier upper hose with the 2.2L engine, part number 8820. The lower hose we used ended up being the wrong one. Another trip to NAPA and we found one that worked. We aren’t sure what application it is, but the part number is 7196.

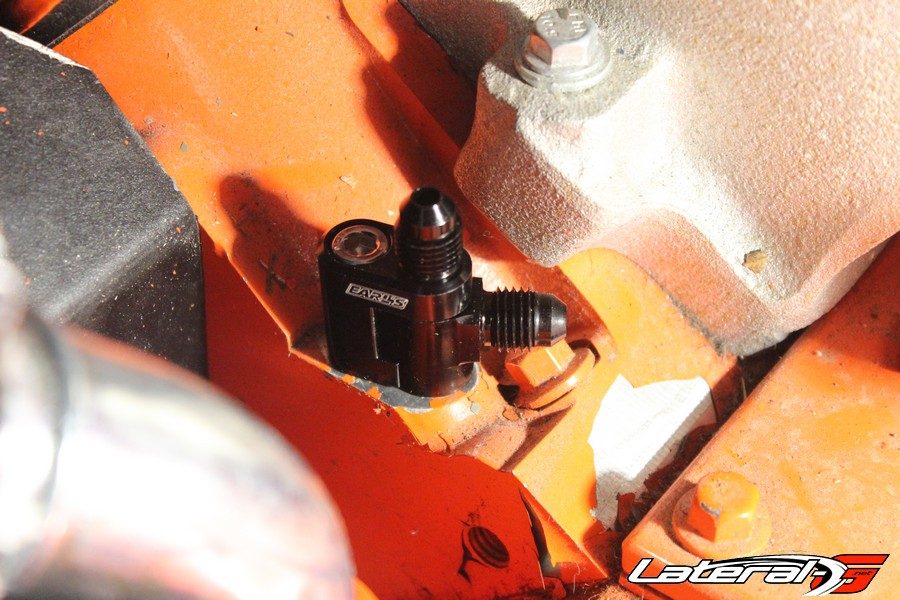

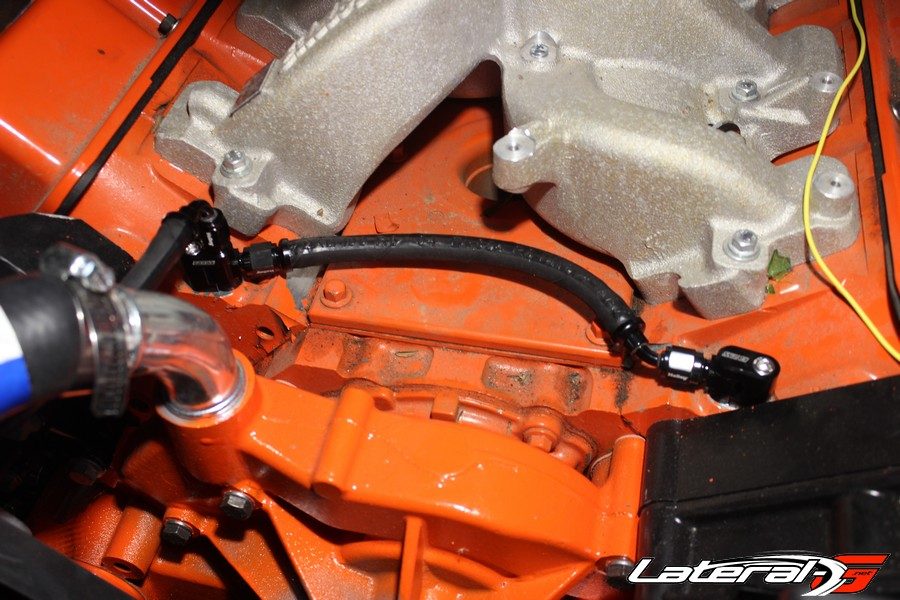

The LS engine requires a steam vent in order to properly remove air pockets from the engine. On this engine the rear ports are blocked from the factory so we decided to keep it that way. In order to plumb in the front vents, we reached out to Holley and grabbed a LS Vent Steam kit. This kit was handy in that it includes two vents that have -4 AN fittings to connect to each other, then go up to the radiator. The kit includes a length of hose to plumb into the radiator, which already has a 1/4 NPT bung and fitting included making this a snap.

The last step was to wire up the radiator fan. This kit from Flex-A-Lite does include all the wiring and a controller to turn the fan on and off. This controller uses a temperature probe that goes into the fins of the radiator to get a reading and kick the fan on. However on this build, the Holley Sniper unit has a wire to trip a fan relay that we opted to use instead.

How we wired the fan was to actually use a heavy duty 70 AMP relay from Painless Performance. This high amperage relay gets power directly from the battery and utilizes the Sniper units fan output to turn the fan on and off. The wiring kit includes heavy duty wiring and plenty of length to mount it remotely.

There are a lot of different radiator manufactures out there to choose from. We chose Flex-A-Lite because they have the track record to back it up and really proved their product in our other projects. We can’t wait to get this ride on the road and cruising!

For more information or to see what they have for your application, hop on Flex-A-Lite’s website or give them a call at (800) 851-1510